Iron-based amorphous alloy and preparation method thereof

A technology of iron-based amorphous alloy and iron-based metal, which is applied in the field of iron-based amorphous alloy and its preparation, and can solve the problems of low amorphous forming ability and low saturation magnetic induction intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

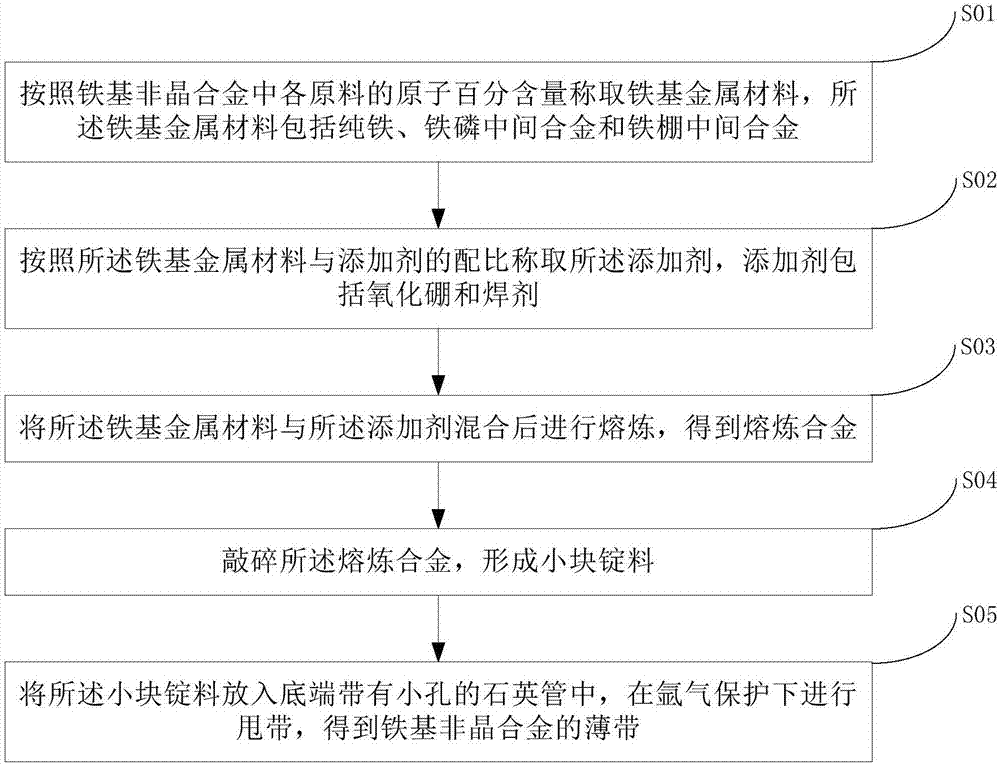

Method used

Image

Examples

Embodiment 1

[0030] An embodiment of the present invention provides an iron-based amorphous alloy, the iron-based amorphous alloy is Fe 85 B 10 P 5 amorphous alloy. Fe 85 B 10 P 5 The raw materials for the preparation of the amorphous alloy include iron-based metal materials and additives, wherein the mass ratio of the iron-based metal materials and additives is 1:3. The iron-based metal material includes pure iron with a purity of 99.99%, an iron-phosphorus master alloy and an iron-boron master alloy. The content of pure iron, iron-phosphorus master alloy and iron-boron master alloy is based on Fe 85 B 10 P 5 The atomic percent content is determined. The additives include boron oxide and high manganese and high silicon type basic flux HJ430, wherein the mass ratio of boron oxide and high manganese high silicon type basic flux HJ430 is 1:1. High manganese and high silicon type alkaline flux HJ430 including SiO 2 , MnO and other components, among them, SiO 2 The mass percentage ...

Embodiment 2

[0039] An embodiment of the present invention provides an iron-based amorphous alloy, the iron-based amorphous alloy is Fe 86 B 9 P 5 amorphous alloy. Fe 86 B 9 P 5 The raw materials for the preparation of the amorphous alloy include iron-based metal materials and additives, wherein the mass ratio of the iron-based metal materials and additives is 1:6. The iron-based metal material includes pure iron with a purity of 99.99%, an iron-phosphorus master alloy and an iron-boron master alloy. The content of pure iron, iron-phosphorus master alloy and iron-boron master alloy is based on Fe 86 B 9 P 5 The atomic percent content is determined. Additives include boron oxide and high manganese and high silicon type basic flux HJ431, wherein the mass ratio of boron oxide and high manganese high silicon type basic flux HJ431 is 2:1. High manganese and high silicon type alkaline flux HJ431 including SiO 2 , MnO and other components, among them, SiO 2 The mass percentage of MnO ...

Embodiment 3

[0042] An embodiment of the present invention provides an iron-based amorphous alloy, the iron-based amorphous alloy is Fe 80 B 12 P 8 amorphous alloy. Fe 80 B 12 P 8 The raw materials for the preparation of the amorphous alloy include iron-based metal materials and additives, wherein the mass ratio of the iron-based metal materials and additives is 1:4. The iron-based metal material includes pure iron with a purity of 99.99%, an iron-phosphorus master alloy and an iron-boron master alloy. The content of pure iron, iron-phosphorus master alloy and iron-boron master alloy is based on Fe 80 B 12 P 8 The atomic percent content is determined. The additives include boron oxide and high manganese and high silicon type basic flux HJ433, wherein the mass ratio of boron oxide and high manganese high silicon type basic flux HJ433 is 2:1. High manganese and high silicon type alkaline flux HJ433 including SiO 2 , MnO and other components, among them, SiO 2 The mass percentage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com