Variable-rigidity hydraulic three-dimensional shock isolation device and method

A technology of variable stiffness and shock isolation, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of high cost, complex structure of combined multi-dimensional shock isolation devices, and inability to isolate vertical earthquakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

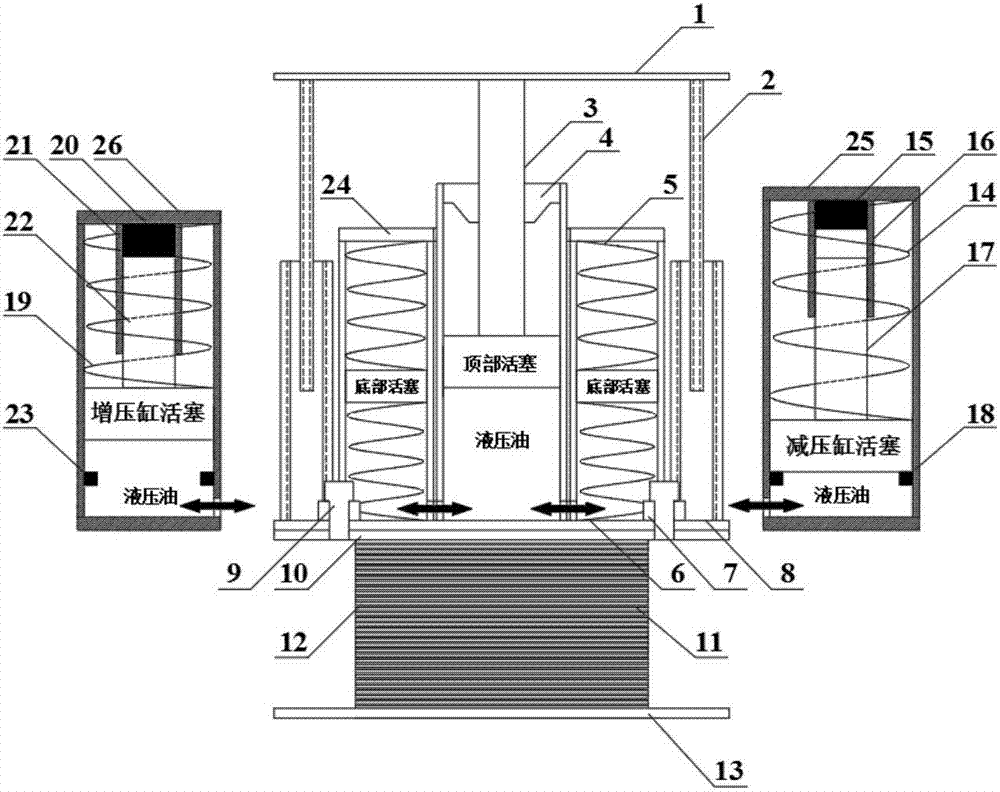

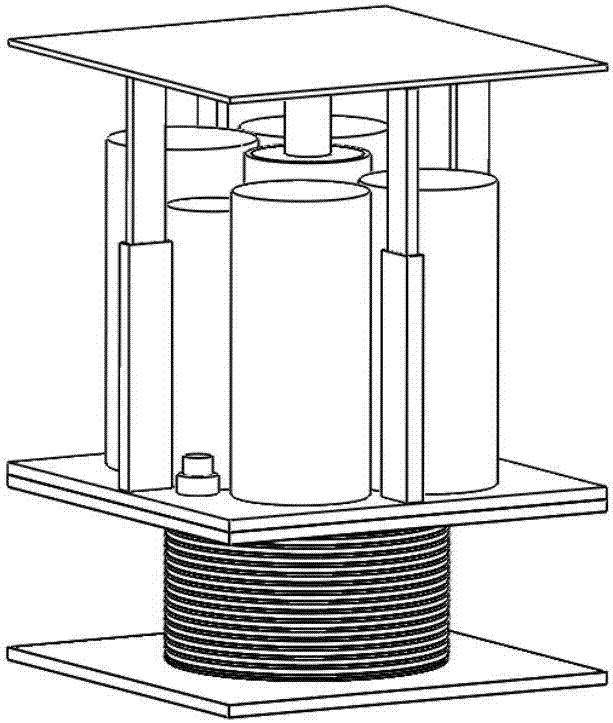

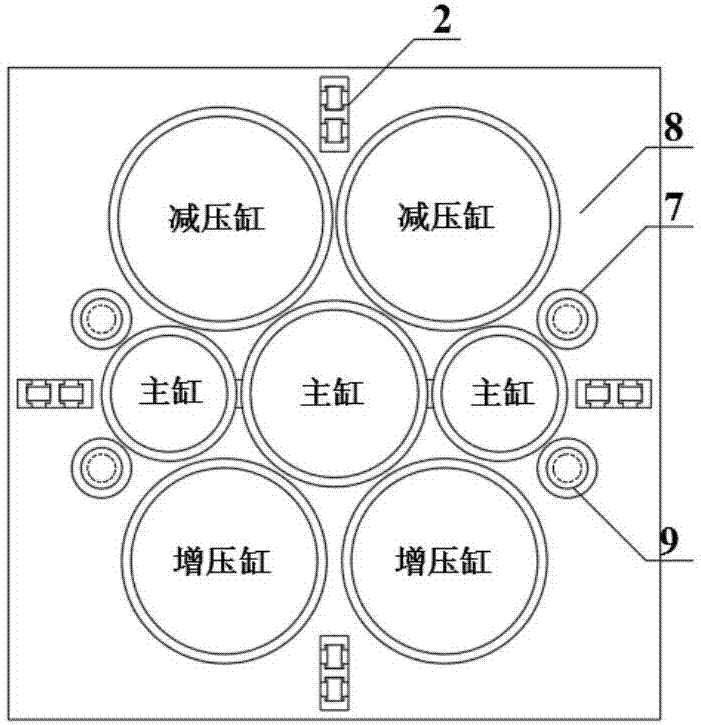

[0052] The following is an example of a three-dimensional vibration isolation device in which the master cylinder includes two bottom piston cavities and has two pressure boosting cylinders and two pressure reducing cylinders as an example: detailed description.

[0053] Taking the three-dimensional vibration isolation device in which the master cylinder includes two bottom piston cavities and two booster cylinders and two decompression cylinders to conduct three-dimensional vibration isolation in a single-layer spherical reticulated shell with a span of 50m as an example, combined with the technical solution and the attached The drawings illustrate specific embodiments of the present invention in detail so that the advantages and features of the present invention can be more readily understood by those skilled in the art.

[0054] The horizontal and vertical fundamental periods of the single-layer spherical reticulated shell with a span of 50 m are 0.318s and 0.284s, respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com