Vertebral artery stent and manufacturing method thereof

A vertebral artery, straight rod technology, applied in the field of medical devices, can solve the problem of not having high radial support force, fatigue resistance and flexibility, etc., to increase radial support force, improve flexibility, and reduce pathological changes. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

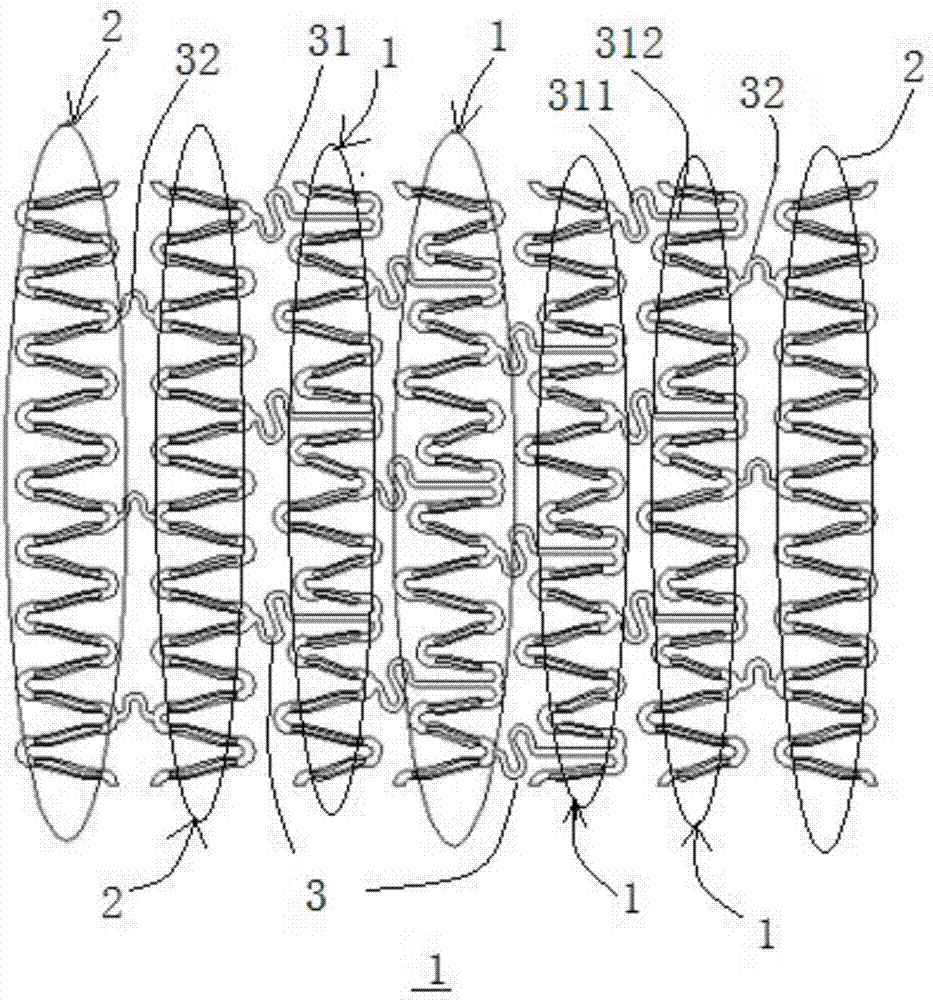

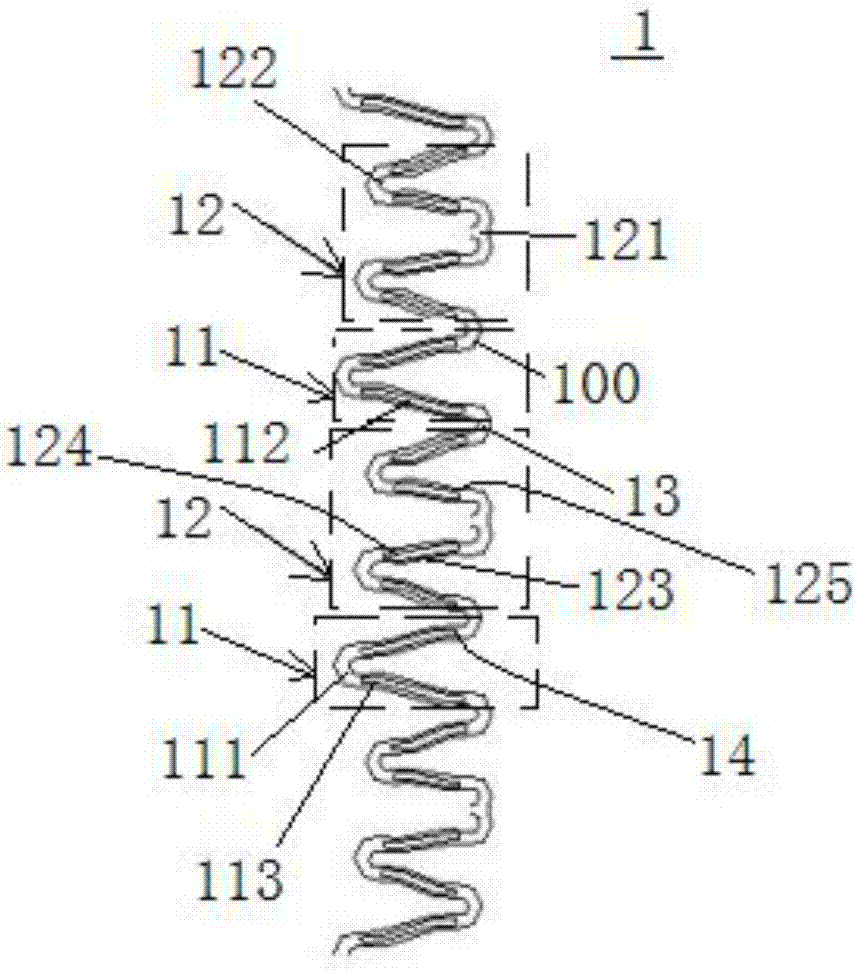

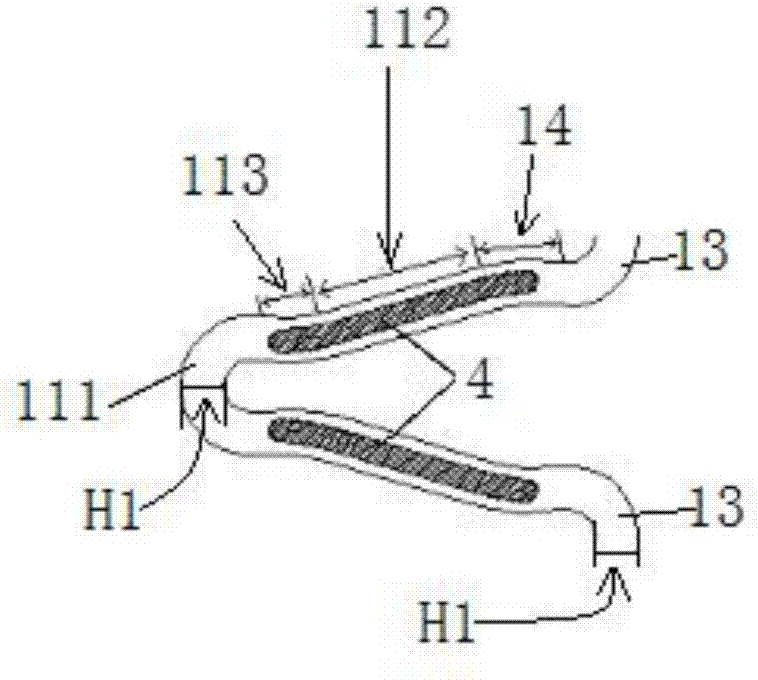

[0085] The vertebral artery stent is composed of 7 first unit ring structures and 16 connection structures, including 4 "n"-shaped first connection structures and 12 second connection structures composed of "s"-shaped curved parts connected to straight parts . The thickness of the stent is 100 μm, and the laser cutting technology is used to cut out the groove loaded with the drug coating. The groove width is 55 μm and the depth is 30 μm. 60%. The width of the first straight rod structure and the second straight rod structure of the first unit ring structure is 96 μm, the ring width of the first ring end structure and the second ring end structure is 91 μm, the first straight rod structure and the second straight rod structure Slightly about 5% wider than the transition structure, the length of the second straight bar structure is 25% shorter than the length of the first straight bar structure.

Embodiment 2

[0087] The vertebral artery stent is composed of 10 first unit ring structures and 22 connection structures, including 4 "n"-shaped first connection structures and 18 second connection structures composed of "s"-shaped curved parts connected to straight parts . The thickness of the stent is 100 μm, and the laser cutting technology is used to cut out the groove loaded with the drug coating. The groove width is 60 μm and the depth is 25 μm. 65%. The width of the first straight rod structure and the second straight rod structure of the first unit ring structure is 107 μm, the ring width of the first ring end structure and the second ring end structure is 91 μm, the first straight rod structure and the second straight rod structure Slightly about 15% wider than the transition structure, the length of the second straight bar structure is 35% shorter than the length of the first straight bar structure.

Embodiment 3

[0089] The vertebral artery stent is composed of 12 first unit ring structures and 20 connection structures, including 8 "n"-shaped first connection structures and 16 second connection structures composed of "s"-shaped curved parts connected to straight parts . The thickness of the stent is 110 μm, and the laser cutting technology is used to cut out the groove loaded with the drug coating. The groove width is 50 μm, and the depth is 30 μm. 70%. The width of the first straight rod structure and the second straight rod structure of the first unit ring structure is 100 μm, the ring width of the first ring end structure and the second ring end structure is 91 μm, the first straight rod structure and the second straight rod structure Slightly about 9% wider than the transition structure, the length of the second straight bar structure is 30% shorter than the length of the first straight bar structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com