Jet type slurry erosion wear testing device and testing method thereof

A technology of wear test and test method, which is applied in the direction of measuring device, test wear resistance, instrument, etc., which can solve the problems of difficult control of coating flatness and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

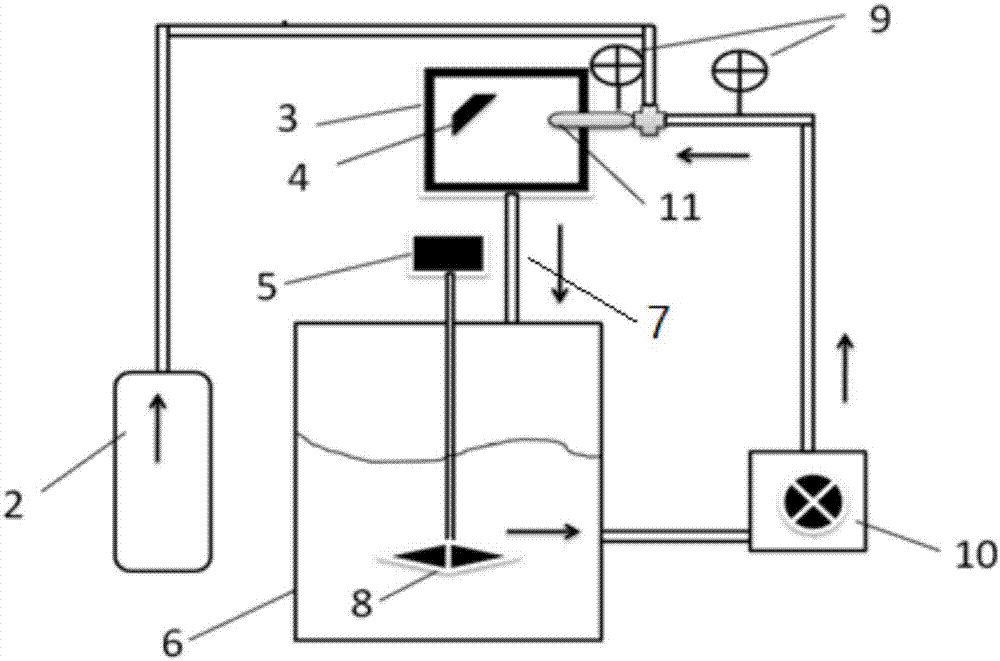

[0065] A kind of jet type slurry erosion wear test device of the present embodiment, such as figure 1 As shown, it consists of a compressed air auxiliary power mechanism, a sample erosion mechanism and a slurry supply mechanism. The compressed air auxiliary power mechanism includes a compressed gas tank 2; the sample erosion mechanism includes a nozzle 1 and a sample chamber 3; The slurry supply mechanism includes a slurry tank 6 and a grinding liquid pump 10 communicated through pipelines; the compressed gas tank 2 communicates with the nozzle 1 through an air pipe; the grinding liquid pump 10 communicates with the nozzle 1 through a grinding liquid pipe; the The sample chamber 3 has a built-in sample 4, the nozzle 1 is inserted into the sample chamber 3, and the mouth of the nozzle 1 faces the sample 4; the slurry tank 6 has a built-in stirrer 5, and the stirring blade 8 on the stirrer 5 extends into the To the bottom of the slurry tank 6 to ensure the uniformity of the slur...

Embodiment 2

[0073] A kind of jet type slurry erosion wear test device of the present embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are: the nozzle 1, the air pipe and the grinding liquid pipe are connected together through a three-way pipe; the grinding liquid pipe and The nozzles 1 are all connected with a pressure gauge 9 to display the flow rate of the slurry, and then the flow rate of the slurry can be controlled by adjusting the power of the grinding liquid pump. The bottom of the sample chamber 3 communicates with the slurry tank 6 through an external return pipe 7, and the slurry is recycled to avoid waste and environmental pollution.

[0074] The test method of a jet type slurry erosion wear test device of the present embodiment, the steps are:

[0075] A. Fix sample 4: fixed sample 4 is facing the nozzle 1;

[0076] B, start stirring: start the agitator 5, and stir the slurry in the slurry tank 6 evenly;

[0077] C. Start ...

Embodiment 3

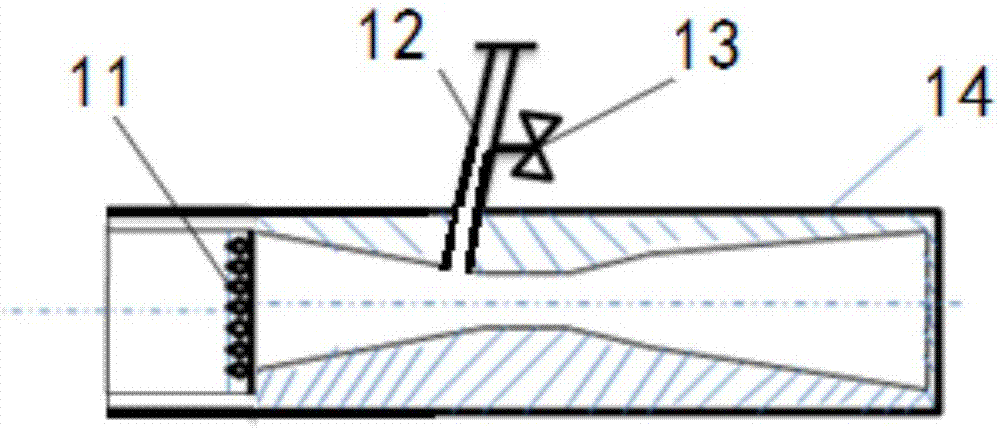

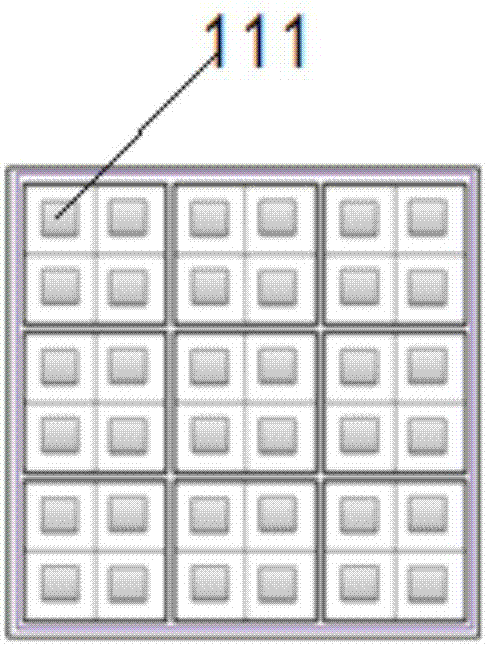

[0080] A kind of jet type slurry erosion wear test device of this embodiment, the basic structure is the same as that of embodiment 2, the differences and improvements are as follows: figure 2 As shown, the nozzle 1 has a Venturi nozzle structure; the port is a plurality of nozzles 11, the throat is connected to the compressed air inlet 12, and the slurry channel 14 at the tail is connected to the grinding liquid pipe; the air inlet pipe of the compressed air inlet 12 is connected to the gas pressure regulator valve 13. The conical inlet of the Venturi nozzle structure has a certain clustering effect, and the throat design can enhance the erosion ability of the slurry, and can also make its distribution on the nozzle 1 section more uniform. The slurry is pumped into the pipeline by the grinding liquid pump 10. Before entering the nozzle 1, the compressed air enters through the compressed air inlet 12 to generate turbulent diffusion in the boundary layer, and exchange energy a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com