Motor driver verification device

A motor driver and verification device technology, applied in motor generator testing, instruments, simulators, etc., can solve problems such as time-consuming and labor-intensive, economic loss, affecting production capacity, etc., so as to shorten the troubleshooting time, prevent motor damage, and ensure The effect of repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described more specifically with reference to the accompanying drawings.

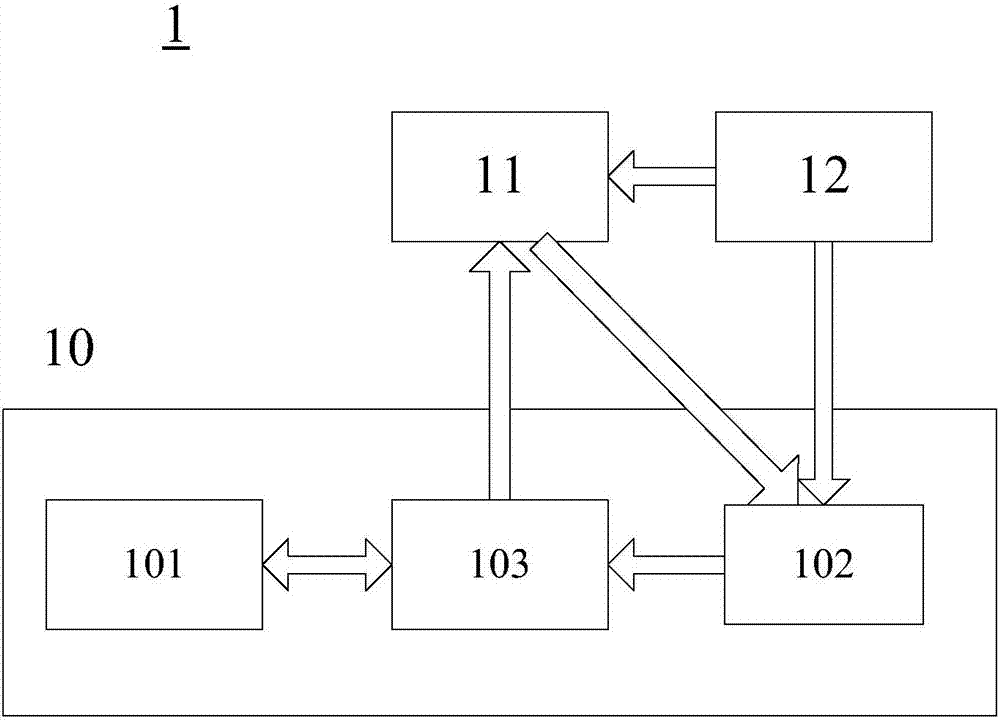

[0026] figure 1 A block diagram of a motor driver verification system 1 including a motor driver verification device 10 according to an embodiment of the present invention is shown.

[0027] Such as figure 1 As shown, the verification system 1 includes a motor driver 11 to be verified, a motor 12 adapted thereto, and a motor driver verification device 10 according to an embodiment of the present invention. The device 10 includes a man-machine interface 101 , a sensor unit 102 and a processing unit 103 . Such as figure 1 As shown, the arrows therein show the signal or data flow relationship between the various components.

[0028] The human-computer interaction interface 101 is used to receive a user's verification instruction for the motor driver 11 . Specifically, the verification instruction may include a series of operations to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com