Semiconductor laser wavelength stabilizing system and realization method

A technology for stabilizing systems and lasers, applied to semiconductor lasers, lasers, laser components, etc., can solve the problems of slow response time, low laser power density, long heat transfer path, etc., and achieve fast response speed, high control precision, and system The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

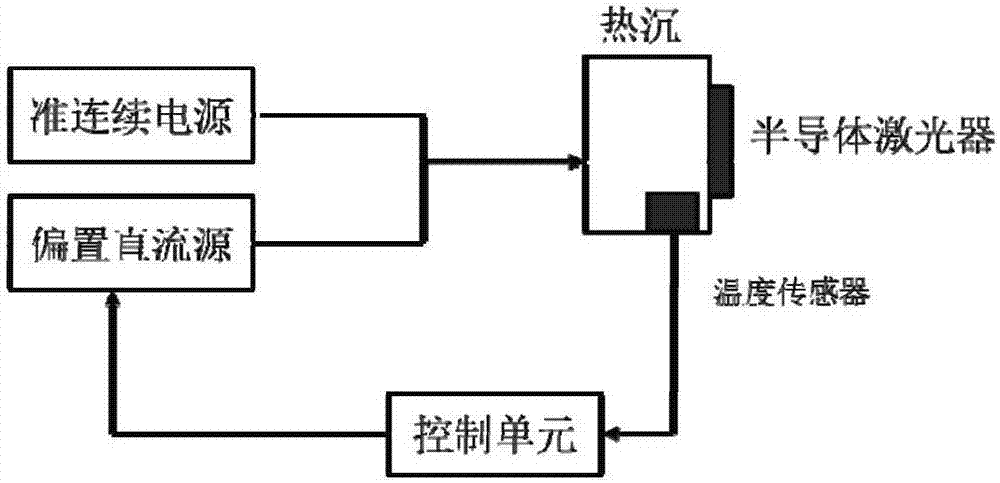

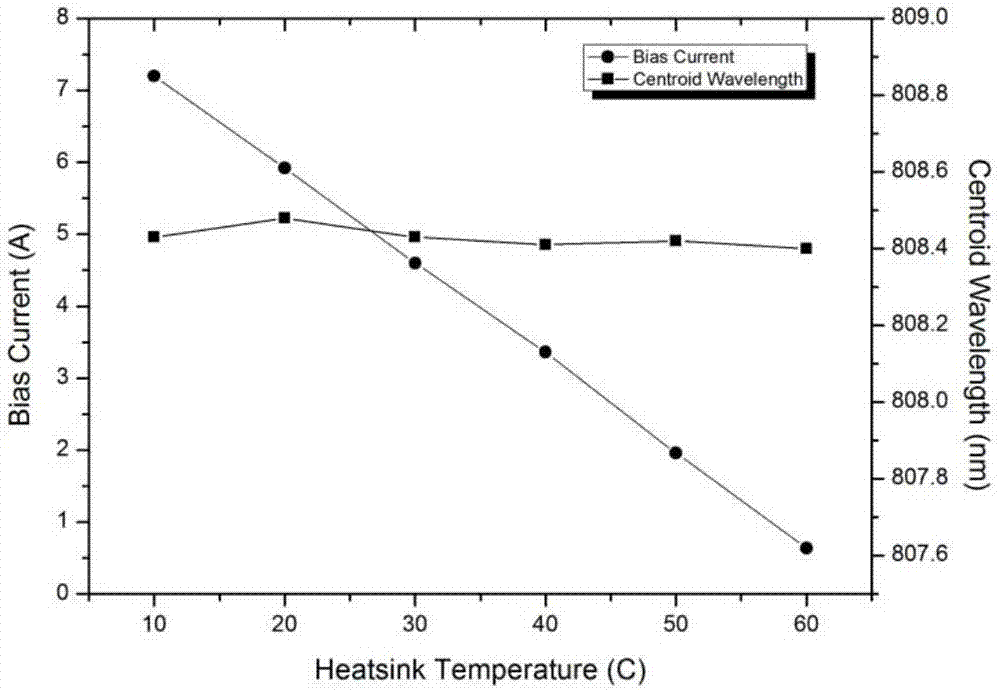

[0030] Such as figure 1 As shown, the semiconductor laser wavelength stabilization system of the present invention includes: a semiconductor laser, a heat sink, a temperature sensor, a control unit, and a driving power supply. The functional relationship between the heat sink temperature and the DC bias current is used as the control parameter, based on the control unit based on the microprocessor (specifically, a single-chip microcomputer, etc.), through the real-time detection of the heat sink temperature, according to the built-in bias current of the control unit and The relationship between the heat sink temperature adjusts the DC bias current accordingly to realize the stability of the output wavelength of the semiconductor laser.

[0031] Various packaging forms are available for semiconductor lasers, specifically conduction-cooled high-power semiconductor lasers (non-water-cooled semiconductor lasers);

[0032] The heat sink is a material with high thermal conductivit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com