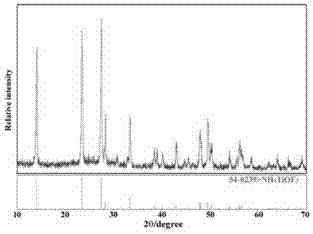

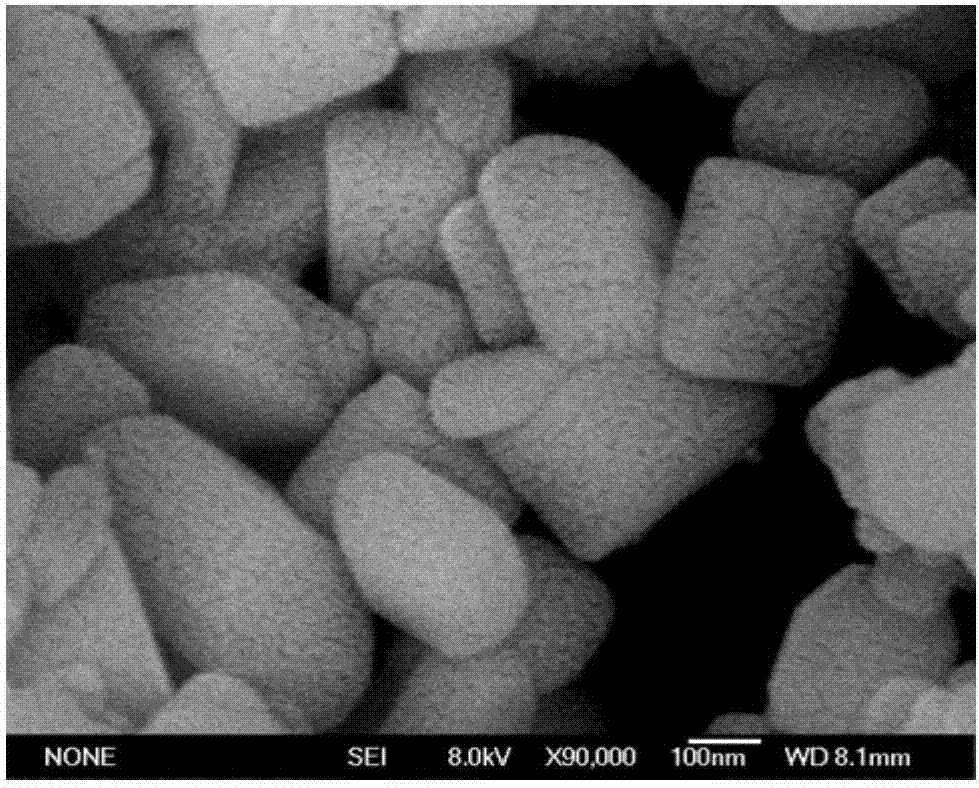

Pt / NH4TiOF3 porous Shaqima-structured photocatalyst and preparation method thereof

A technology of photocatalyst and ammonium fluoride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that the preparation method of porous Sachima structure photocatalyst has not been provided, and achieve dispersion Easy to control, simple process and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

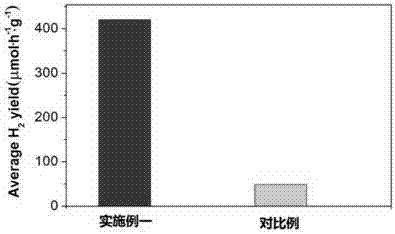

Embodiment 1

[0016] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 4mg chloroplatinic acid obtain mixed solution;

[0017] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180°C for 8 hours;

[0018] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0019] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

Embodiment 2

[0021] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 2mg chloroplatinic acid obtain mixed solution;

[0022] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180° C. for 8 hours;

[0023] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0024] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

Embodiment 3

[0026] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 8mg chloroplatinic acid obtain mixed solution;

[0027] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180° C. for 8 hours;

[0028] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0029] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com