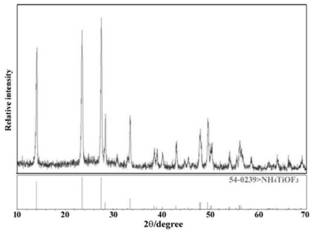

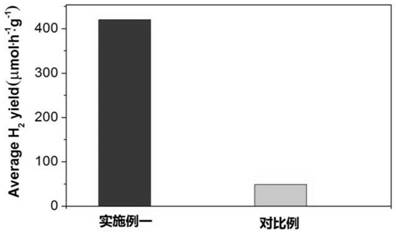

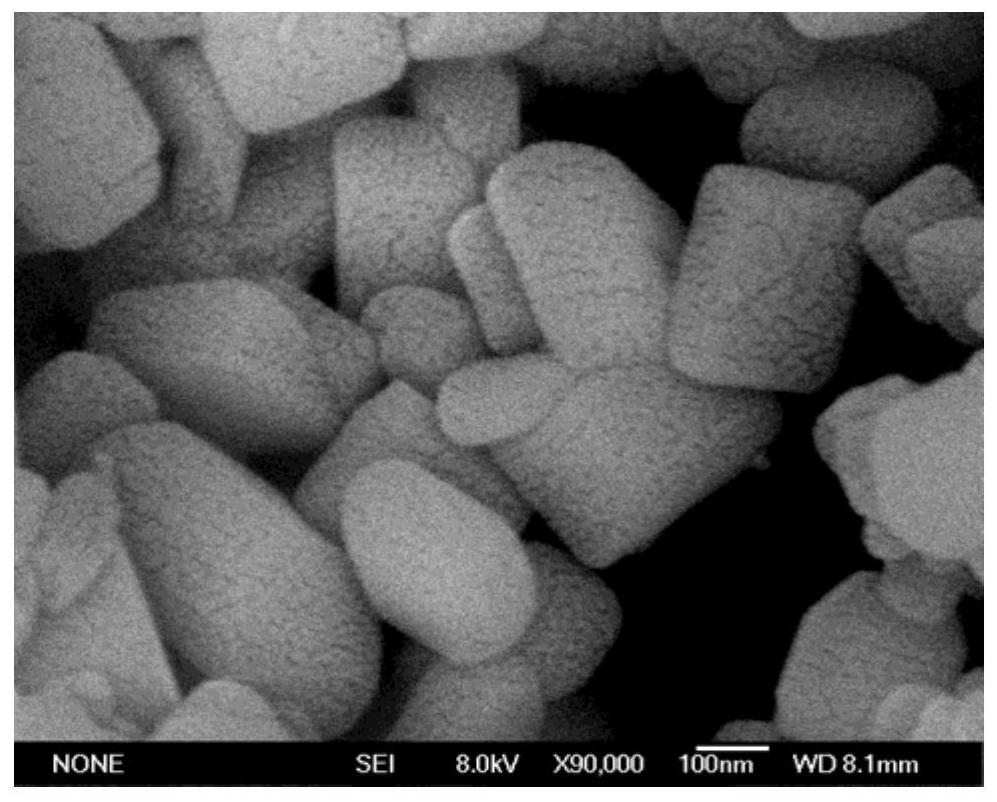

a pt/nh 4 tiof 3 Porous Sachima Structured Photocatalyst

A photocatalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems that have not yet been provided, and achieve easy control of dispersion, low preparation cost, and high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 4mg chloroplatinic acid obtain mixed solution;

[0017] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180°C for 8 hours;

[0018] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0019] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

Embodiment 2

[0021] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 2mg chloroplatinic acid obtain mixed solution;

[0022] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180° C. for 8 hours;

[0023] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0024] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

Embodiment 3

[0026] (1) Get 1ml dipropylene glycol, add 30ml acetic acid successively, 0.4g ammonium fluoride, 0.24g titanium sulfate, 8mg chloroplatinic acid obtain mixed solution;

[0027] (2) Transfer the mixed solution obtained in step (1) to a high-pressure reactor lined with polytetrafluoroethylene, and react at a constant temperature of 180° C. for 8 hours;

[0028] (3) Naturally cool the reaction solution obtained in step (2) to room temperature, centrifuge, and repeat washing twice with deionized water and ethanol respectively to obtain Pt / NH 4 TiOF 3 Precipitate;

[0029] (4) Dry the precipitate obtained in step (3) in a 70°C drying oven to obtain Pt / NH 4 TiOF 3 Porous Sachima structured photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com