Critical layer stress adjusting method for solving cracking of multi-layer film caused by electron beam deposition

A technology of electron beam deposition and critical layer, which is applied in the direction of coating, ion implantation plating, metal material coating process, etc., and can solve problems such as film cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

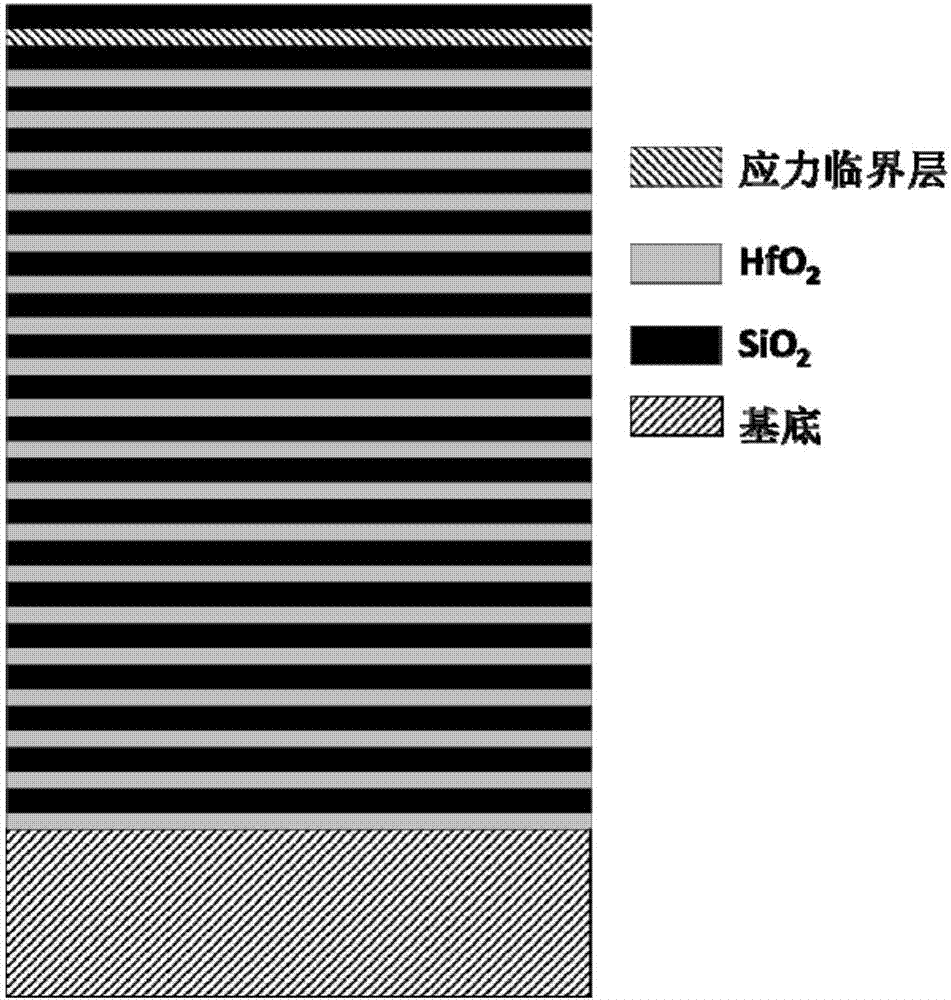

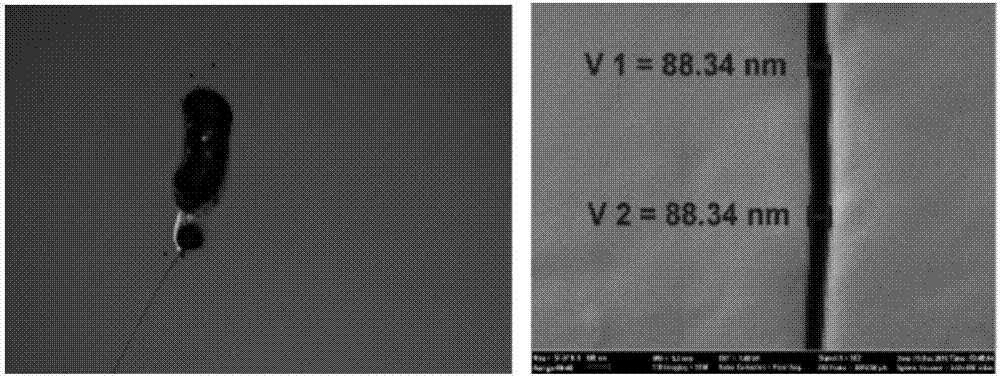

[0032] The high refractive index material is HfO 2 , the low refractive index material is SiO 2 , the total number of film layers is 40, and the multilayer film with a total thickness of 8 μm is an example, illustrating the method for controlling the critical layer stress of the present invention to solve the cracking of electron beam deposited multilayer film, the method comprising the following steps:

[0033] 1) Input parameters to the computer:

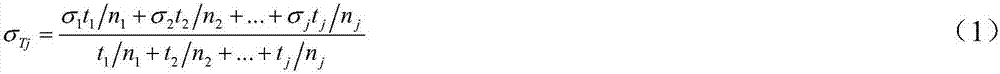

[0034] including the design wavelength λ D , High refractive index material refractive index n H (1.92), low refractive index material refractive index n L (1.44), the stress σ of the high refractive index material prepared by electron beam deposition technology in the deposition environment H (360Mpa), the stress σ of the low refractive index material prepared by electron beam deposition technology in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com