Method for identifying the type of clogging in a membrane filtration apparatus

A membrane filtration, enzyme solution technology, applied in chemical instruments and methods, applications, membrane technology and other directions, can solve problems such as limitations, and achieve the effect of saving the use of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

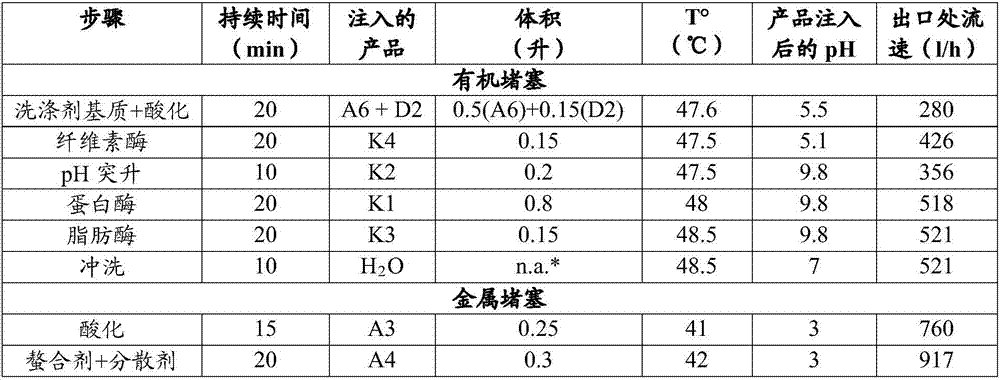

[0053] In order to determine the nature of the clogging present in the ultrafiltration unit (300 liter volume) used for the extraction of lupine, the method of the invention was carried out according to the steps shown in the following table:

[0054]

[0055] A6 = Detergent base with chelating, dispersing and wetting agents

[0056] D2 = acid solution (phosphoric acid + nitric acid)

[0057] K4 = Aqueous solution of cellulase-based enzymes

[0058] K2 = alkaline solution (caustic soda + caustic potash)

[0059] K1 = protease-based enzyme aqueous solution

[0060] K3 = lipase-based enzyme aqueous solution

[0061] A3 = acid solution (HCl)

[0062] A4 = solution containing chelating agent and dispersing agent

[0063] n.a.* = Not Applicable: Loss of circulating flow for 10 consecutive minutes.

[0064] A first example carried out according to the method of the invention shows that the clogging of the ultrafiltration device is mainly due to the presence of particles wit...

Embodiment 2

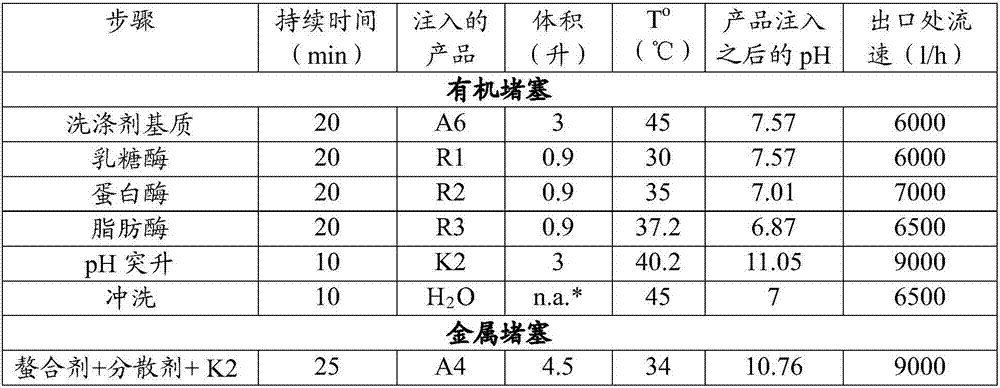

[0067] In order to determine the nature of clogging present in nanofiltration and reverse osmosis filtration units (1500 liter volume) used for the treatment of milk, the method of the invention was carried out according to the steps shown in the table below:

[0068]

[0069] A6 = Detergent base with chelating, dispersing and wetting agents

[0070] R1 = Lactase-based enzyme aqueous solution

[0071] K2 = alkaline solution (1:1 ratio of caustic soda + caustic potash)

[0072] R2 = protease-based enzyme aqueous solution

[0073] R3 = lipase-based enzyme aqueous solution

[0074] A4 = solution containing chelating agent and dispersing agent

[0075] n.a.* = Not Applicable: Loss of circulating flow for 10 consecutive minutes

[0076] A second example performed according to the method of the present invention shows that the clogging of nanofiltration and reverse osmosis filtration devices is mainly due to the presence of particles with an affinity for lipase and protease. ...

Embodiment 3

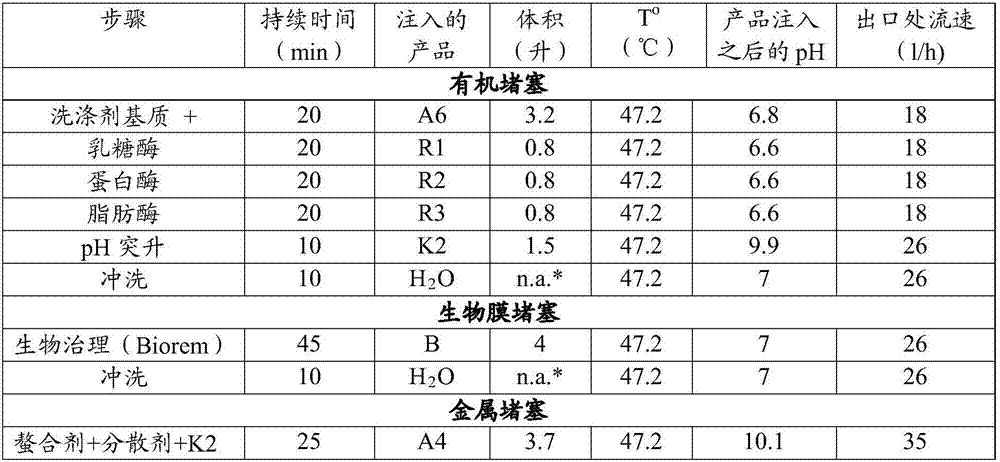

[0079] In order to determine the nature of clogging present in a reverse osmosis filter unit (3000 liter volume) used for the treatment of milk, the method of the invention was carried out according to the steps shown in the table below:

[0080]

[0081] A6 = Detergent base with chelating, dispersing and wetting agents

[0082] R1 = Lactase-based enzyme aqueous solution

[0083] K2 = alkaline solution (1:1 ratio of caustic soda + caustic potash)

[0084] R2 = protease-based enzyme aqueous solution

[0085] R3 = lipase-based enzyme aqueous solution

[0086] A4 = solution containing chelating agent and dispersing agent

[0087] B = A composition comprising a detergent component and an enzyme component, wherein the detergent component contains chelating agents, dispersants and wetting agents, and the enzyme component contains polysaccharases, laccases and proteases

[0088] n.a.* = Not Applicable: Loss of circulating flow for 10 consecutive minutes.

[0089] The method a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com