Welding wire box with moisture protection

A technology of welding wire box and welding wire, which is applied in the direction of providing/exhausting shielding gas devices, welding equipment, manufacturing tools, etc., can solve problems such as high cost, escape, and increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

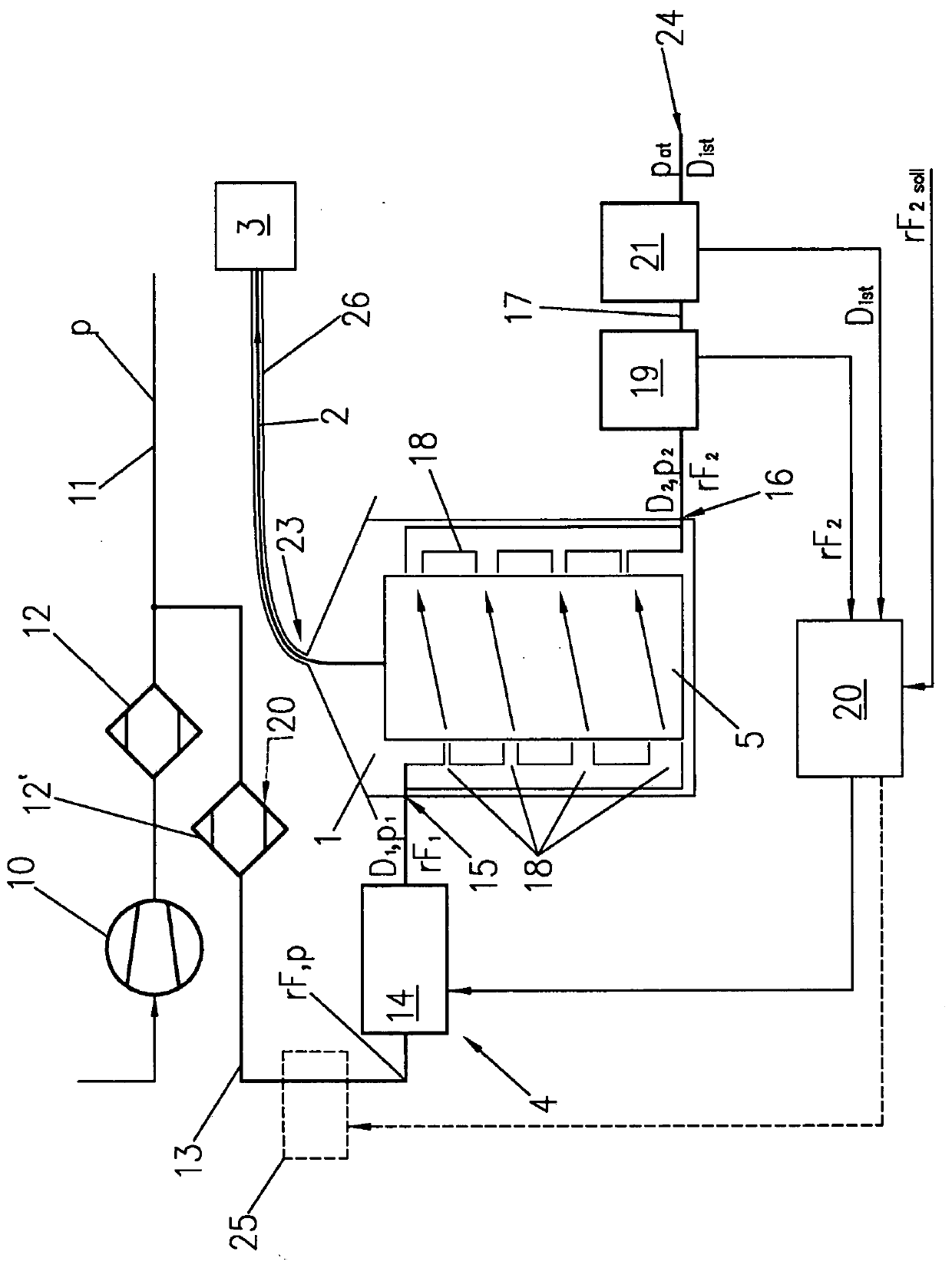

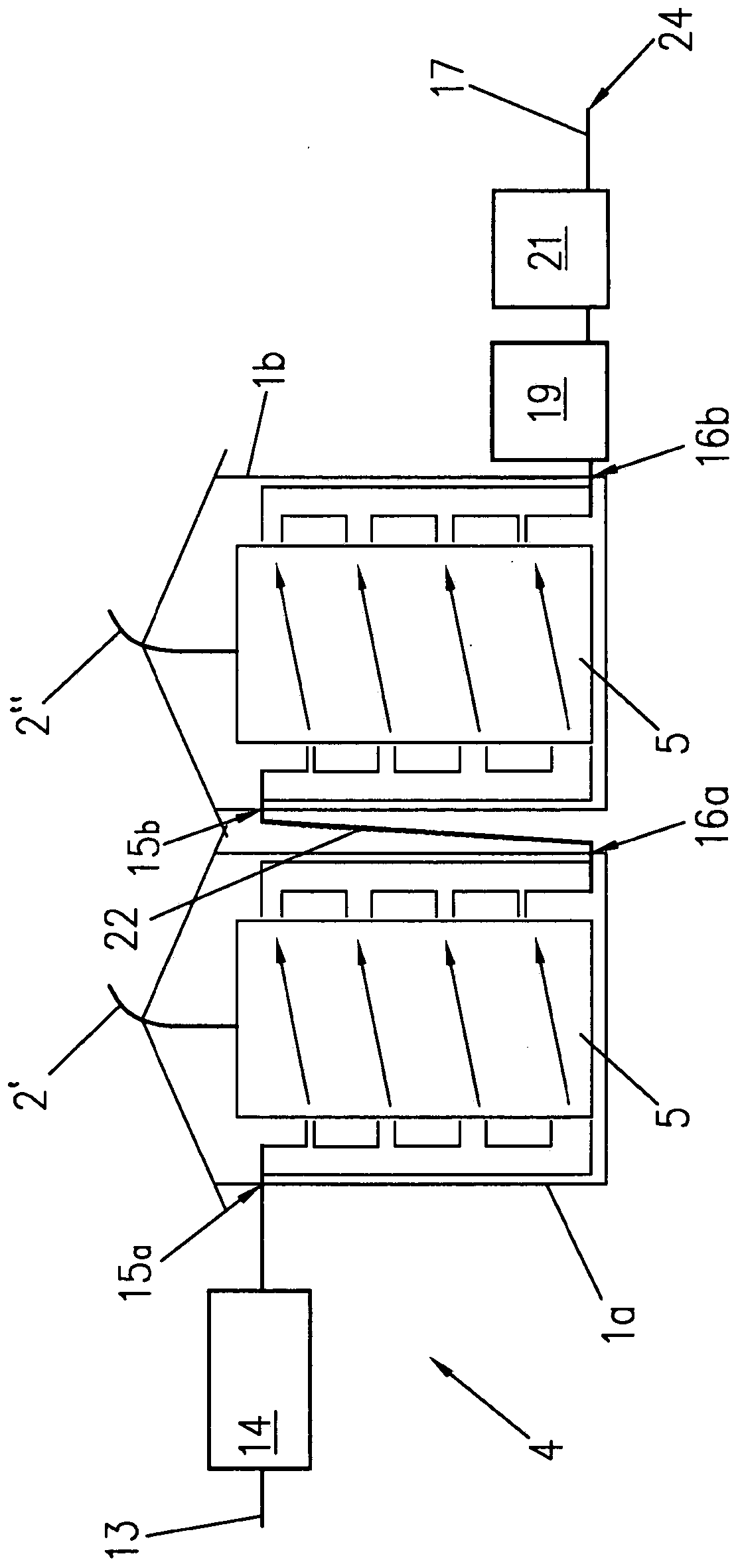

[0021] figure 1 A welding wire box 1 is shown, in which a welding wire 2 is placed in a sufficiently known manner, from which it is removed by a welding process 3 not shown in detail here and used for welding. Welding devices with auxiliary devices required for the welding process 3 , such as a shielding gas supply, are sufficiently known and are not shown or described in detail here. The feed unit for feeding the welding wire 2 can be arranged in the welding wire box 1 , but also in the welding device itself and / or in the welding torch. The welding wire 2 is usually placed in the welding wire box 1 in the form of a welding wire coil 5, as in figure 1 shown in . In order to protect the welding wire 2 against the moisture contained in the ambient air, a guard 4 is provided, which will be described in detail below.

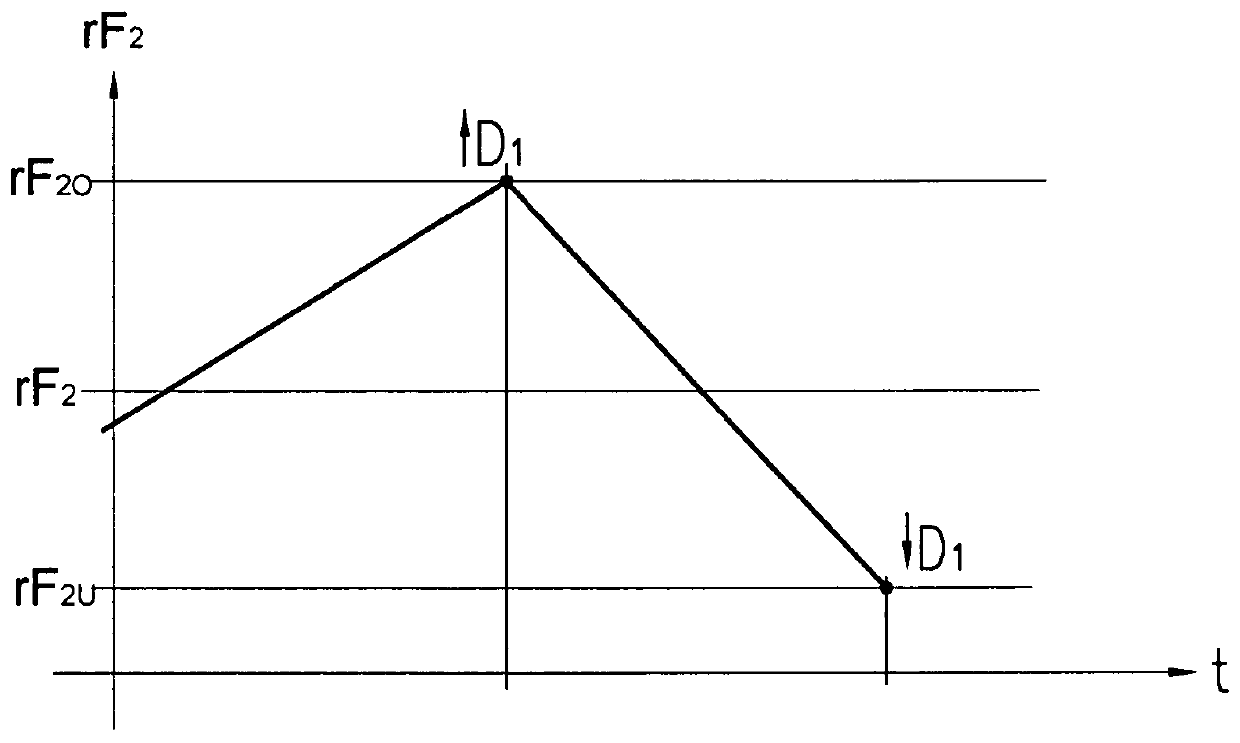

[0022] Ambient air is compressed by a compressor 10 and scavenging air is produced at a pressure p and is made available via a compressed air line 11 . In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com