Power distribution on a vessel

A technology for ships and switchboards, applied in ship propulsion, ship construction, electrical components, etc., to achieve the effects of scale reduction, avoiding low-voltage cables, and high cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

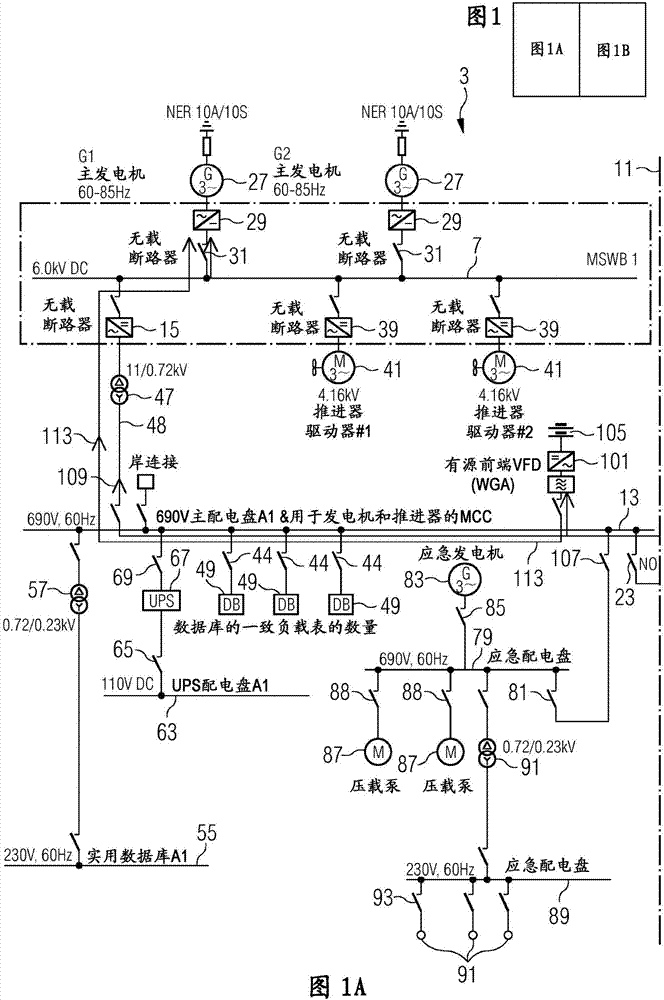

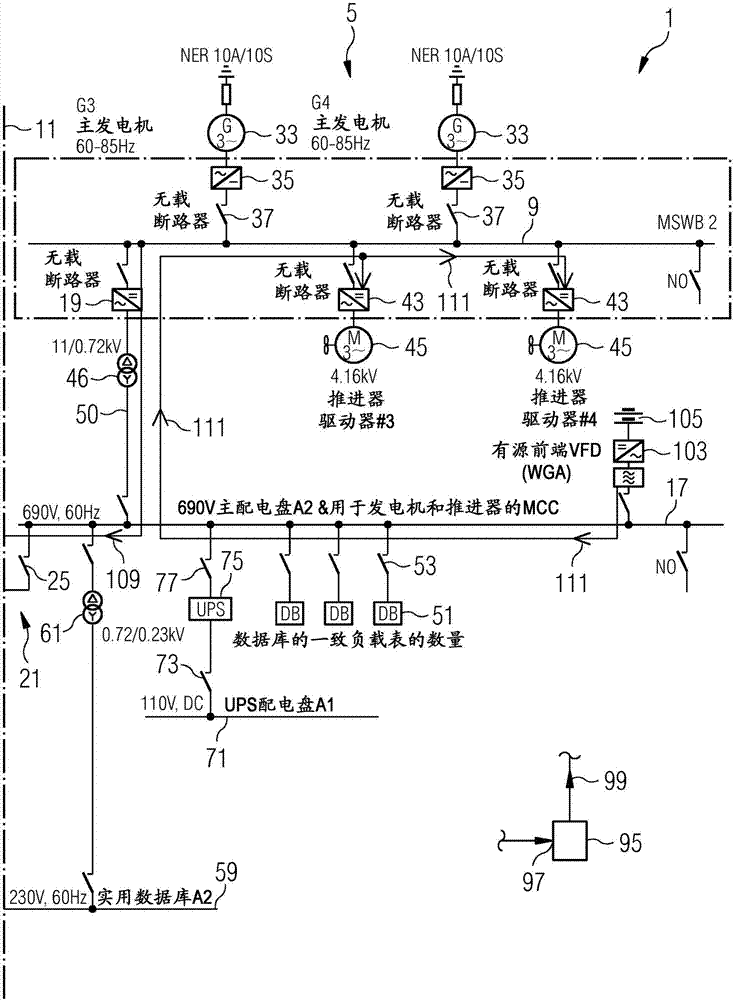

[0045] A schematic circuit diagram of a structure 1 for power distribution on a ship illustrates a first system 3 and a second system 5 sharing several features. The first system 3 comprises a first DC bus 7 operating at a first medium voltage (6.0 kVDC in the example shown). Similarly, the second system 5 comprises a second DC bus 9 operating at a second medium voltage, eg between 5kV and 10kV DC. As indicated in the figure, the first DC bus bar 7 and the second DC bus bar 9 are separated by a barrier 11 , which are independent of and / or spaced from each other. Thereby, there is no direct connection between the first DC bus 7 and the second DC bus 9 .

[0046] The first system 3 also comprises a first AC bus 13 operating at low voltage (690V, 60Hz AC in the example shown). A first inverter 15 is coupled between the first DC bus 7 and the first AC bus 13 . The second system 5 comprises a second AC bus 17 operating at low voltage (ie 690V, 60Hz AC). A second inverter 19 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com