One-step pelletizer

A granulator, fluidized bed granulation technology, applied in the direction of mixer, special binder granulation, powder suspension granulation, etc., can solve problems such as dead angle, uneven granulation, dead bed, etc., to achieve efficiency and The effect of quality improvement, overall granulation uniformity, and dead angle reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

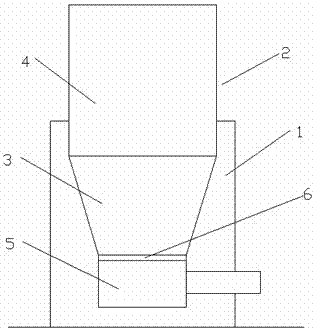

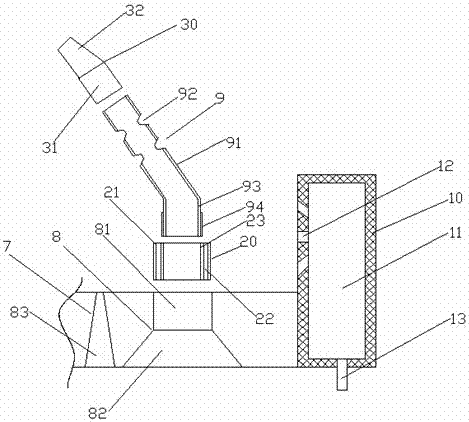

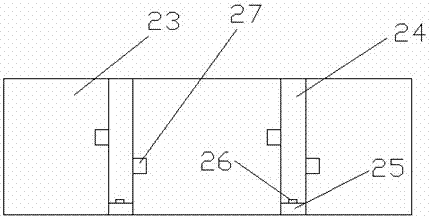

[0028] Such as Figure 1-3 As shown, the present invention relates to a one-step granulator, comprising a frame 1, on which a fluidized bed granulation chamber 2 is arranged, and the fluidized bed granulation chamber 2 includes a lower material bin 3 and an upper The granulation bin 4 is provided with an air inlet bin 5 at the bottom of the material bin 3, and an air flow distribution plate 6 is arranged between the air inlet bin 5 and the material bin 3. The flow mentioned in the present invention The chemical bed granulation chamber 2 is the prior art, including its material bin 3 and the granulation bin 4, which are all prior art, and will not be repeated here. The present invention improves the air flow distribution plate 6 inside it, and the air flow distribution The plate 6 includes a plate body 7, and a plurality of air holes 8 are formed on the plate body 7, and an air flow pipe 9 is arranged on the air air hole 8, and the flow direction of the air flow out of the air ...

Embodiment 2

[0035] Such as Figure 4As shown, the difference from Embodiment 1 is that the nozzle 30 in the present invention includes a connecting pipe 31, and the connecting pipe 31 is threadedly connected to the end of the air flow pipe 9, and the end of the connecting pipe 31 is The sealing end 33 forms an air outlet groove 34 around the wall body of the end, so that different airflows are formed around the whole area, and the overall material and adhesive are mixed more uniformly and fully, and the collapse of the bed and the death of the bed are not easy to occur. Phenomenon, so that the granulation is more uniform, to ensure product quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com