Tubular pile inner hole thread milling machine and tubular pile inner hole thread groove manufacturing method

A technology for threading machines and pipe piles, applied in thread cutting tools, thread cutting machines, manufacturing tools, etc., can solve the problems of different depths of thread grooves, which cannot meet the needs of use, low frictional resistance inside the pile, and complicated processing process, etc., and saves money. The effect of energy, construction quality assurance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

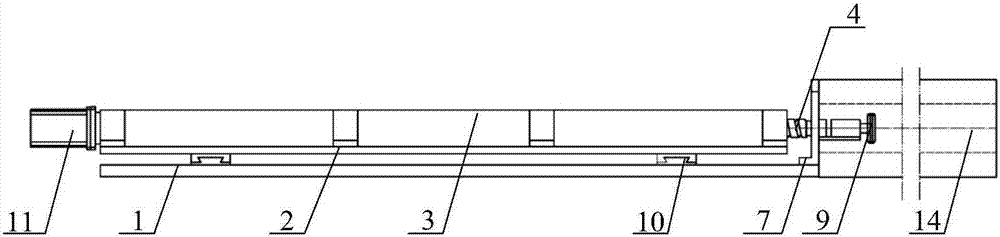

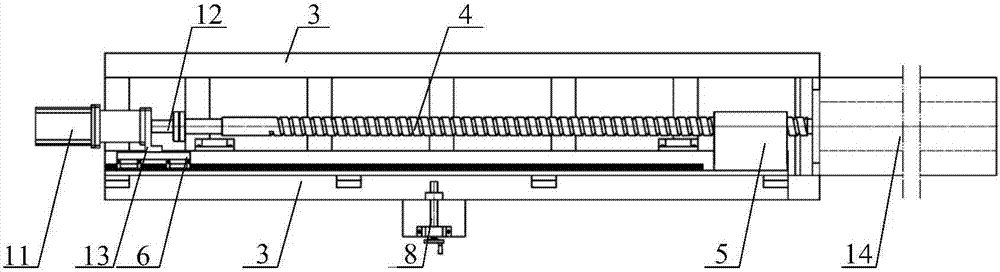

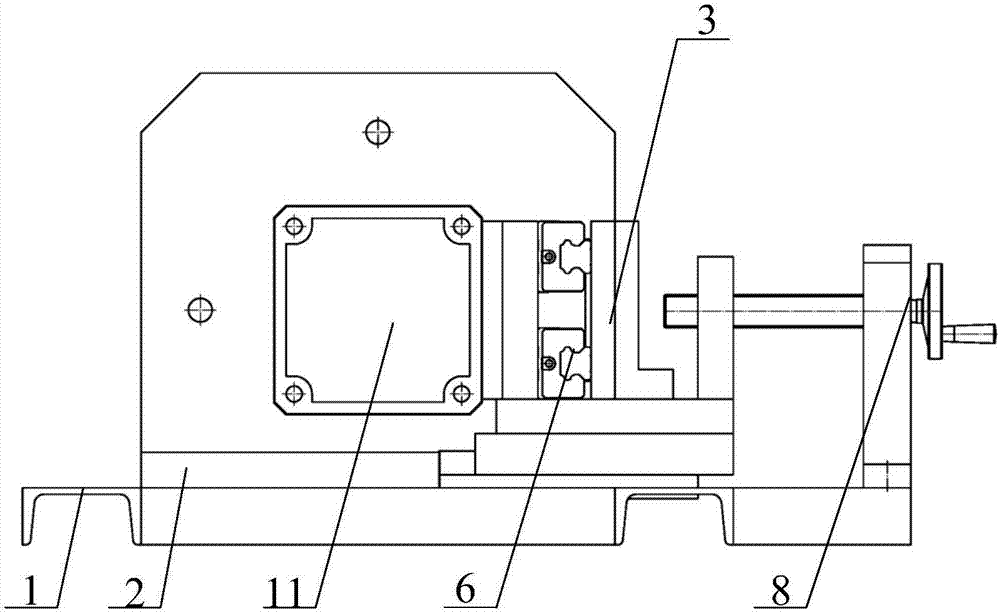

[0021] The technical solution of the invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 3 As shown, the pipe pile inner hole thread grinding machine of the present invention includes a bracket 1, a base 2, a feed device 8, a first linear guide rail pair 6, a second linear guide rail pair 10, a lead screw 4, a nut sleeve 5, a servo Motor 11 and diamond inlaid type forming grinding wheel 9. Two second linear guide rails are longitudinally arranged on the bracket 1, the base 2 is installed on the bracket 1 through the second linear guide rail pair 10, and vertical plates 3 parallel to each other are respectively supported on both sides of the base 2 in the length direction. The base 2 is connected with the feed device 8, the feed device 8 is fixed on the bracket 1, and the feed device 8 controls the base 2 to slide along the second linear guide rail, so as to realize the longitudinal movement of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com