Device capable of conveniently improving girth welding quality of pipelines

A circular welding and quality technology, applied in the direction of auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of reducing the service life of pipelines, and achieve the effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

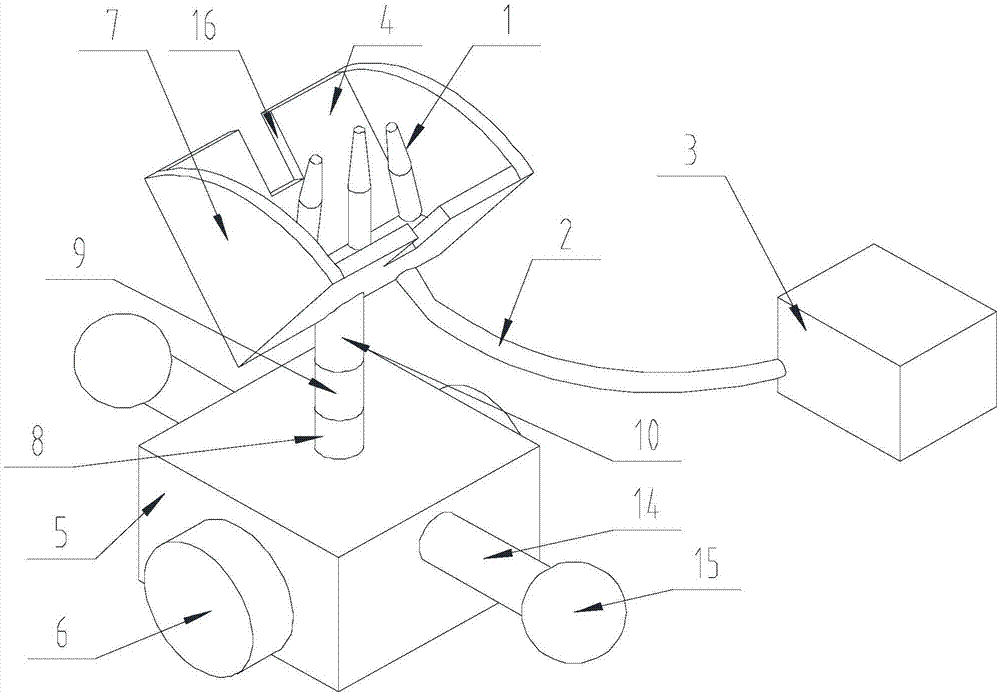

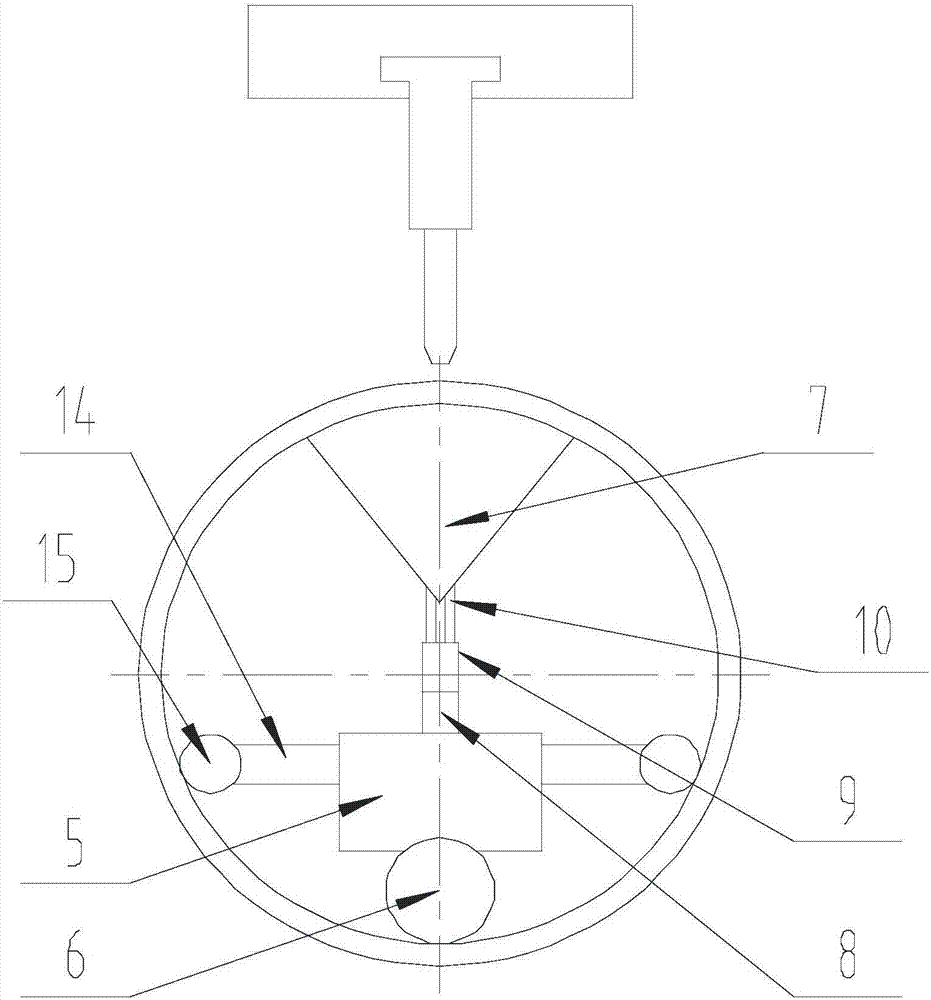

[0027] Such as Figure 1-Figure 3 As shown, the present invention is convenient to improve the device of pipeline annular welding quality, comprises gas nozzle 1, gas pipeline 2, gas storage tank 3 connected in sequence and bent plate 4 connected in sequence, support block 5, roller 6 and motor, described The cross section of the bent plate 4 is L-shaped, and the outer convex end of the bent part of the bent plate 4 is connected to the upper surface of the support block 5, and baffles 7 are arranged at the two opposite open ends of the bent plate 4, so Described baffle plate 7 is fan-shaped plate, and one side on its fan-shaped surface is connected with one side of the open end of bent plate 4, and the other side on the fan-shaped surface is connected with the other side of the open end of bent plate 4, and the curved edge of baffle plate 7 is far away from the bent plate. The bending part of the bending plate 4, the gas injection end of the gas nozzle 1 is located on the side...

Embodiment 2

[0030] The present invention is based on embodiment 1, and the present invention is further described.

[0031] Such as Figure 1-Figure 3 As shown, the present invention is a device for improving the welding quality of pipe rings. A connecting rod 8 is arranged between the bent plate 4 and the supporting block 5 . The connecting rod 8 is a telescopic rod, and its axis is perpendicular to the supporting block 5 . Adjust the length of the connecting rod 8 according to the pipes with different diameters, so that the gas nozzle 1 can be as close as possible to the welded part where the pipes are connected.

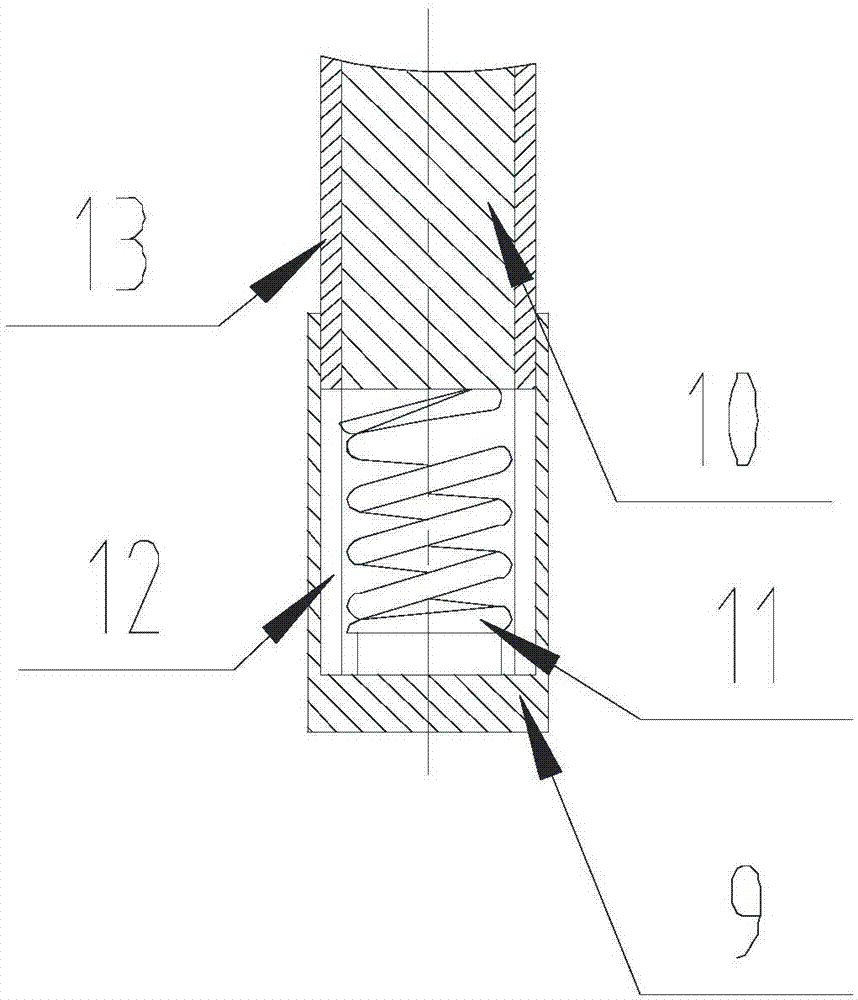

[0032] Further, between the connecting rod 8 and the bent plate 4, a sleeve 9 and a moving rod 10 whose axes coincide with each other are sequentially arranged, one end of the sleeve 9 is connected to the end of the connecting rod 8 away from the support block 5, and The axis of the sleeve 9 coincides with the axis of the connecting rod 8;

[0033] A spring 11 is arranged i...

Embodiment 3

[0037]The present invention is based on embodiment 1, and the present invention is further described.

[0038] Such as Figure 1-Figure 3 As shown, the present invention facilitates the device for improving the welding quality of pipe rings. A support rod 14 is arranged on a pair of opposite sides of the support block 5, and the axis of the support rod 14 is perpendicular to the pair of opposite sides of the support block 5, and At the same time, it is perpendicular to the axis of the roller 6 , and the pair of opposite sides are perpendicular to the upper surface of the support block 5 . The support rod 14 is a telescopic rod, and the end of the support rod 14 away from the support block 5 is provided with a contact ball 15 . The length of the support rod 14 is adjusted so that the contact ball 15 is in contact with the inner wall of the pipeline, so as to avoid the situation that the air delivery device is toppled due to vibration during welding.

[0039] Further, a relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com