Locally reinforced tubular fabric covering film used for in-situ window opening and preparation method thereof

A technology of local reinforcement and tubular fabric, which is applied in the direction of heating/cooling fabric, fabric, fabric surface trimming, etc., can solve the problems of unfavorable delivery of curved aortic shape matching, poor patient fit, increase the rigidity of vascular stents, etc., and achieve enhanced durability Sexuality and in vivo long-term service performance, avoiding adverse consequences, and curbing the effects of potential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

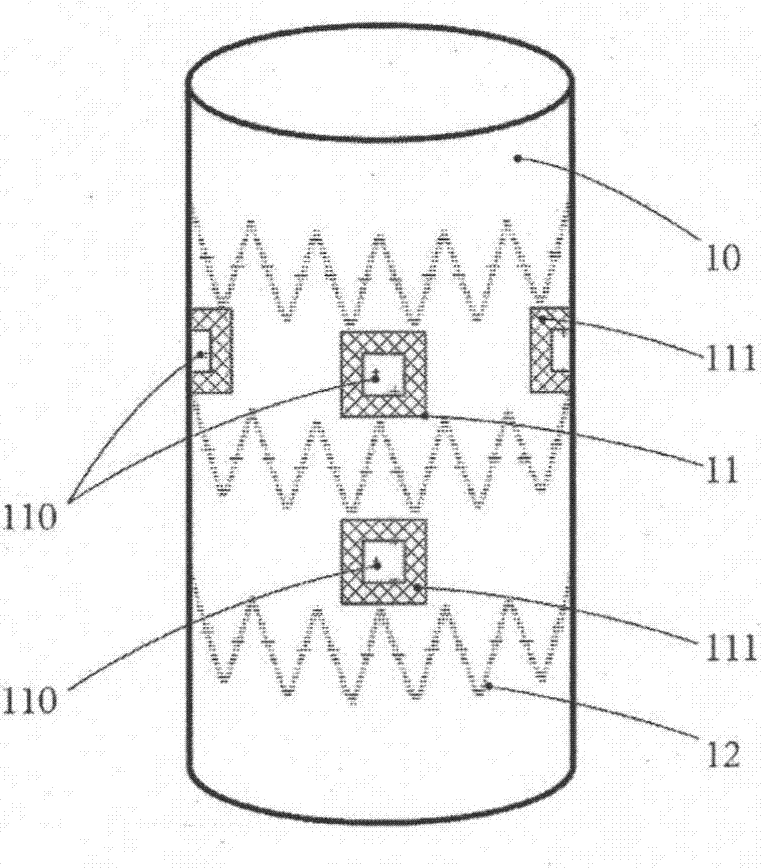

[0034] Such as figure 1 As shown, it is a schematic diagram of the partial reinforcement of the tubular fabric coating with the membrane support for in-situ fenestration. The body is composed of a fully open window domain 11 and a base domain 10. The fully open window domain 11 is composed of a non-reinforced structural domain 110 and a partially reinforced structural domain 111 surrounding the non-reinforced structural domain 110; the fabric of the partially reinforced structural domain 111 The maximum tear strength of the tissue is greater than the maximum tear strength of the non-reinforced domain 110 fabric tissue. A metal bracket 12 is fixed on the side of the tubular fabric-covered body.

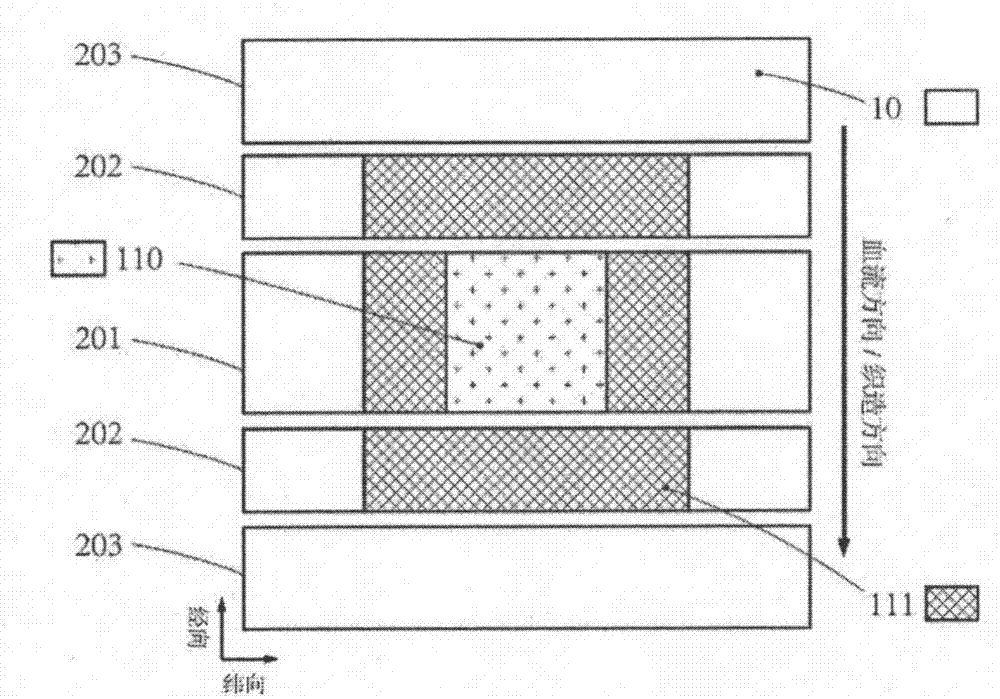

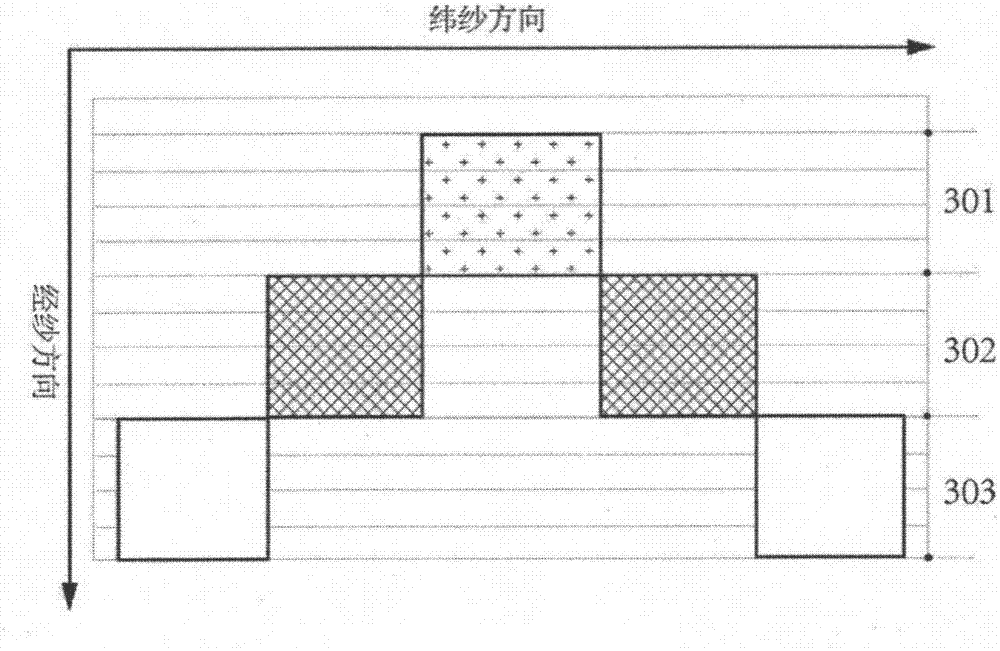

[0035] Such as figure 2 As shown, it is a schematic diagram of a cardboard for preparing a partially reinforced tubular fabric film with a film support for in-situ window opening. The cardboard map is divided into a first cardboard image 201, a second cardboard image 202, and a thir...

Embodiment 2

[0043] Such as figure 1 As shown, it is a schematic diagram of the partial reinforcement of the tubular fabric coating with the membrane support for in-situ fenestration. The body is composed of a fully open window domain 11 and a base domain 10. The fully open window domain 11 is composed of a non-reinforced structural domain 110 and a partially reinforced structural domain 111 surrounding the non-reinforced structural domain 110; the fabric of the partially reinforced structural domain 111 The maximum tear strength of the tissue is greater than the maximum tear strength of the non-reinforced domain 110 fabric tissue. A metal bracket 12 is fixed on the side of the tubular fabric-covered body.

[0044] Such as figure 2 As shown, it is a schematic diagram of a cardboard for preparing a partially reinforced tubular fabric film with a film support for in-situ window opening. The cardboard map is divided into a first cardboard image 201, a second cardboard image 202, and a thir...

Embodiment 3

[0052] Such as figure 1As shown, it is a schematic diagram of the partial reinforcement of the tubular fabric coating with the membrane support for in-situ fenestration. The body is composed of a fully open window domain 11 and a base domain 10. The fully open window domain 11 is composed of a non-reinforced structural domain 110 and a partially reinforced structural domain 111 surrounding the non-reinforced structural domain 110; the fabric of the partially reinforced structural domain 111 The maximum tear strength of the tissue is greater than the maximum tear strength of the non-reinforced domain 110 fabric tissue. A metal bracket 12 is fixed on the side of the tubular fabric-covered body.

[0053] Such as figure 2 As shown, it is a schematic diagram of a cardboard for preparing a partially reinforced tubular fabric film with a film support for in-situ window opening. The cardboard map is divided into a first cardboard image 201, a second cardboard image 202, and a third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com