Heat pipe and preparation method thereof

A technology of junction heat pipes and heat pipes, applied in the field of junction heat pipes and their preparation, can solve the problems of reducing the service life of junction heat pipes, affecting the heat transfer performance of junction heat pipes, and prone to deformation, etc., achieving low production costs, improving anti-deformation functions, and improving The effect of stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

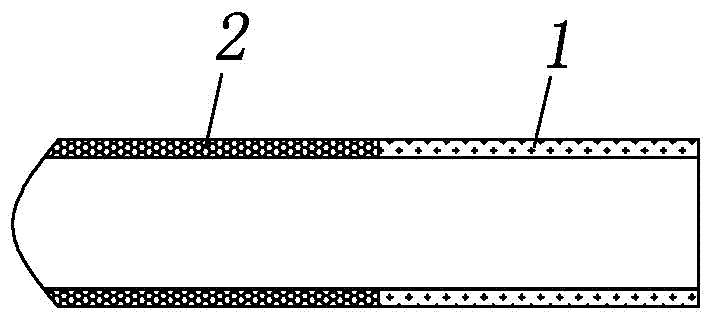

[0024] The embodiment is basically as attached figure 1 Shown: provide a junction heat pipe, including a tube shell, a tube core close to the inner wall of the tube shell and a working liquid sealed in the tube shell, the tube shell includes a boron nitride section 1 and a white corundum section 2, wherein the boron nitride section 1 occupies 1 / 2 of the length of the shell, white corundum section 2 occupies 1 / 2 of the length of the shell, the outer diameter of the shell is 65mm, the inner diameter is 55mm, and the height is 125mm; and the free end of boron nitride section 1 is round shape, the free end of the white corundum segment 2 is a protrusion.

[0025] The preparation method of the heat junction tube in this embodiment includes the following steps:

[0026] A. Material preparation: heat white corundum to 2200°C to molten state by electric arc, and heat boron nitride to 2800°C to molten state by electric arc;

[0027] B. Injection molding: first inject molten white cor...

Embodiment 2

[0033] A junction heat pipe provided in this implementation includes a tube shell, a tube core close to the inner wall of the tube shell and a working liquid sealed in the tube shell. The tube shell includes a boron nitride section 1 and a white corundum section 2, wherein the boron nitride section 1 occupies 1 / 3 of the length of the shell, white corundum section 2 occupies 2 / 3 of the length of the shell, the outer diameter of the shell is 80mm, the inner diameter is 70mm, and the height is 140mm; and the free end of boron nitride section 1 is round shape, the free end of the white corundum segment 2 is a protrusion.

[0034] The preparation method of the heat junction tube in this embodiment includes the following steps:

[0035] A. Material preparation: heating white corundum to 2350°C to molten state by electric arc, and heating boron nitride to 2900°C to molten state by electric arc;

[0036] B. Injection molding: first inject molten white corundum into the stamping mold,...

Embodiment 3

[0042] A junction heat pipe provided in this implementation includes a tube shell, a tube core close to the inner wall of the tube shell and a working liquid sealed in the tube shell. The tube shell includes a boron nitride section 1 and a white corundum section 2, wherein the boron nitride section 1 occupies 1 / 6 of the length of the shell, white corundum section 2 occupies 5 / 6 of the length of the shell, the outer diameter of the shell is 100mm, the inner diameter is 90mm, and the height is 165mm; and the free end of boron nitride section 1 is round shape, the free end of the white corundum segment 2 is a protrusion.

[0043] The preparation method of the heat junction tube in this embodiment includes the following steps:

[0044] A. Material preparation: heat white corundum to 2500°C to molten state by electric arc, and heat boron nitride to 3200°C to molten state by electric arc;

[0045] B. Injection molding: first inject the white corundum in the molten state into the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com