A six-degree-of-freedom double-parallel type heavy swing platform with load balancing devices

A balancing device and load balancing technology, applied in teaching models, instruments, educational appliances, etc., can solve the problems of low safety of super large loads, reduced motor output power, and no improvement in carrying capacity, so as to improve flexibility and dynamic response, Guarantee safety and reliability, and the effect of super large load-bearing structure rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

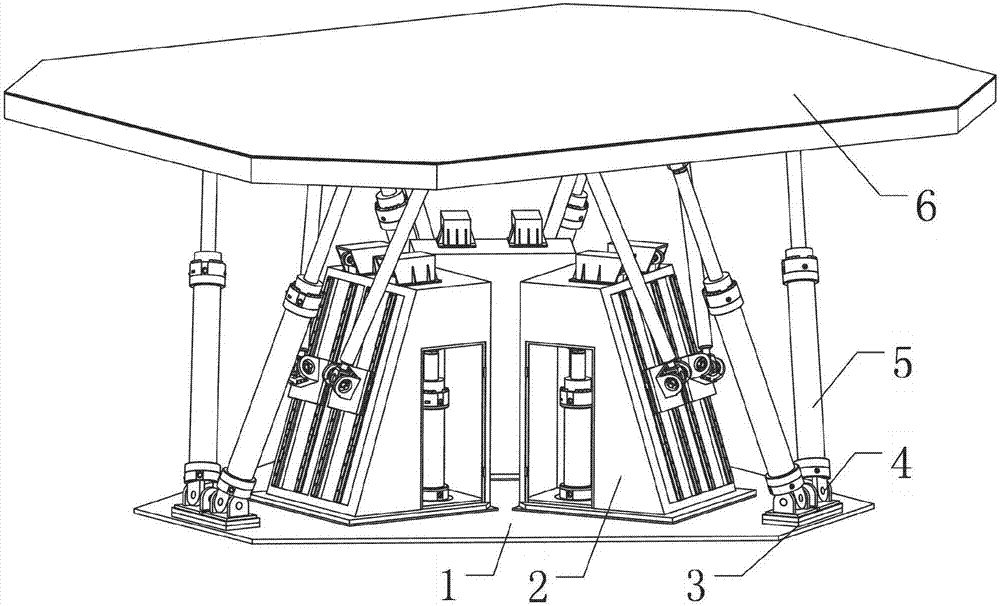

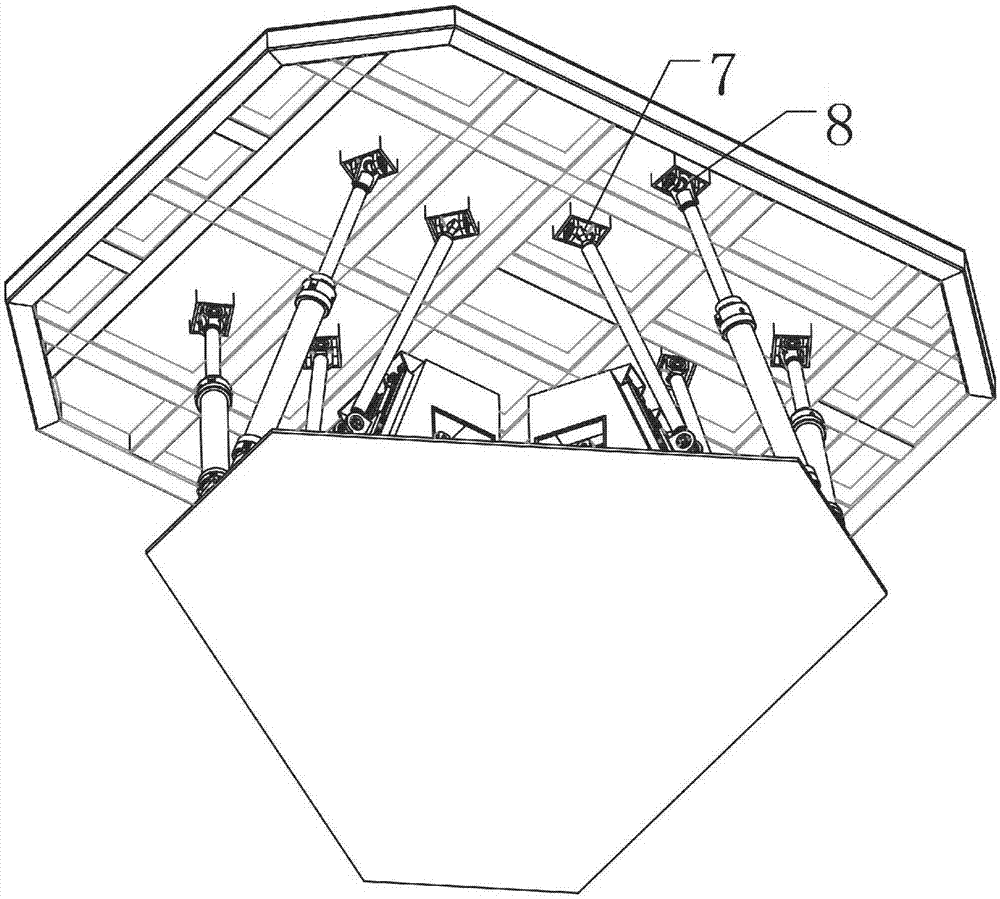

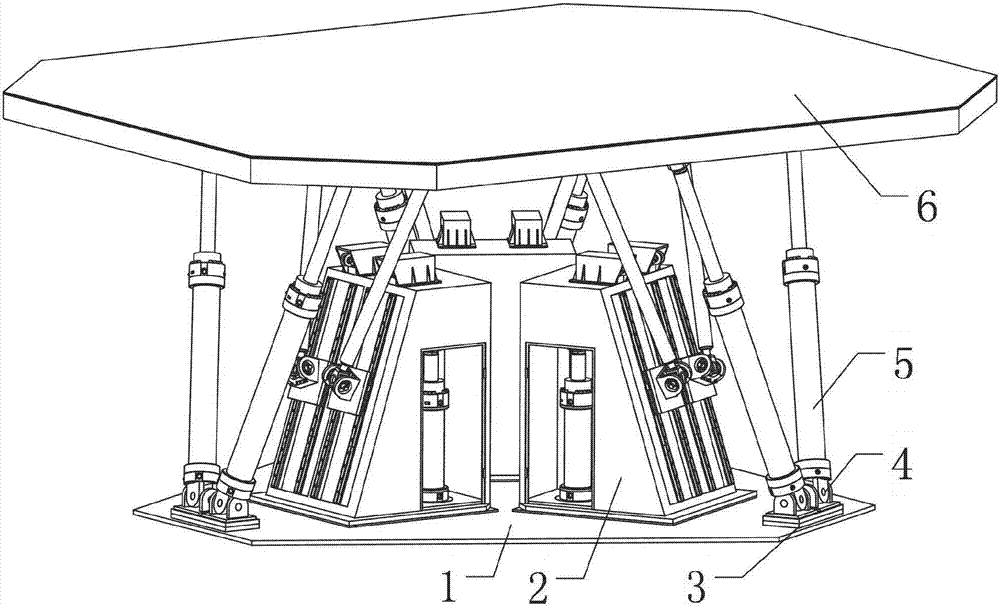

[0027] exist figure 1 , figure 2 In the schematic diagram of a six-degree-of-freedom double-parallel heavy-duty swing table with a load balancing device shown, three load balancing devices 2 are evenly distributed and fixed in the middle of the lower floor, and three bosses 3 are respectively fixed outside the middle of the three load balancing devices On the lower bottom plate of the lower base plate, the ends of the six driving branches 5 are respectively connected to the three bosses through the second universal hinge 4 as a group, and the telescopic ends are respectively connected to the bearing platform 6 through the second spherical hinge 8, adjacent to each other. The ball joints of the two branches of the machine are arranged evenly on the bearing platform as a group.

[0028] Such as Figure 5 , Figure 6 As shown, the load balancing device is fixedly connected to the lower base plate through the right-angled trapezoidal seat 2-1, and the right-angled trapezoidal ...

Embodiment 2

[0030] Such as image 3 and Figure 7 As shown, the cylinder barrels of the two groups of balance hydraulic cylinders 2-12 arranged in the cavity of the right-angled trapezoidal seat are fixedly connected with the bottom of the trapezoidal seat, and the movable pulley 2-13 is installed at the end of the cylinder rod. Four second fixed pulleys 2-14, one end of the four chain ropes are fixedly connected with the connecting seat respectively, and the other ends respectively bypass the first fixed pulley located at the upper end of the trapezoidal seat, the second fixed pulley inside the inclined surface of the trapezoidal seat and the balance hydraulic pressure The movable pulley at the end of the cylinder rod is fixedly connected to the top in the cavity of the trapezoidal seat; other components and connection relations are the same as in Embodiment 1.

Embodiment 3

[0032] Such as Figure 4 and Figure 8Shown, be located at an end of two double columns 2-16 in the right angle trapezoidal seat cavity and be fixed on the trapezoidal seat bottom, its other end is a free end, two counterweights 2-15 pass guide wheel and two double The uprights coincide, and the two chain ropes form a group, one end of which is fixedly connected to the connecting seat, and the other end is fixedly connected to the counterweight by bypassing the two pulleys of the first fixed pulley block; other components and connection relationship and implementation Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com