Making method of preserved meat

A production method and bacon technology, which are applied in the preservation of meat/fish with chemicals, food science, etc., can solve the problems of high salt content and easy to exceed the oxidation value of bacon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

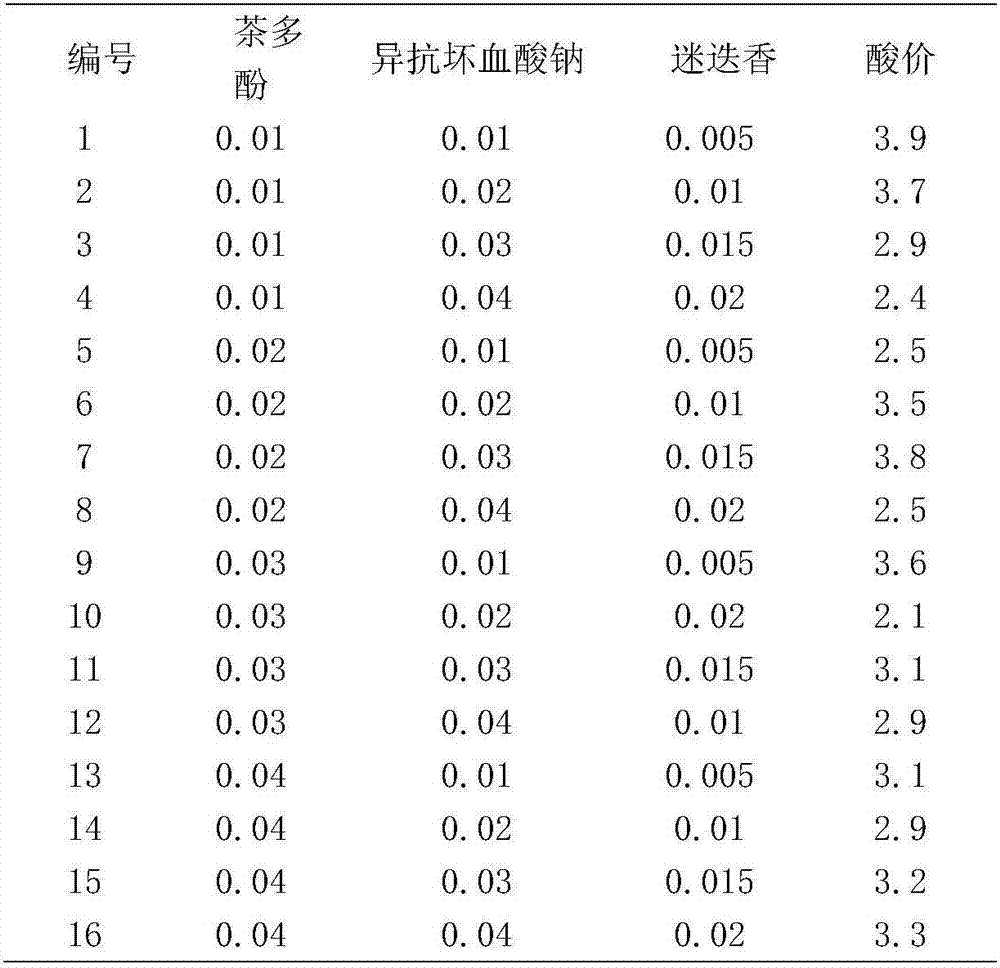

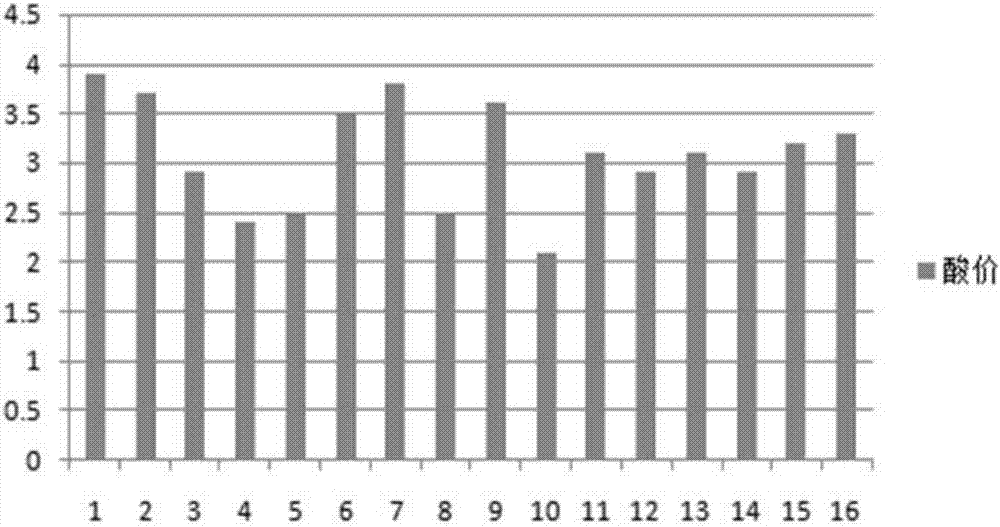

Image

Examples

Embodiment 1

[0017] Example 1, in order to ensure that it meets the national food oxidation value standard and can prepare bacon with good export taste under the condition of low salt, one of the embodiments of the present invention is as follows. The method for making bacon specifically includes the following steps. First, The raw meat is frozen at minus 5°C for 2 hours, which makes it easier to cut the meat. If the freezing time is too short or too long, it will affect the cutting and shaping of the meat; after the meat is frozen, take it out and cut it into strips. Then weigh the weight, taking the preparation of 100kg raw meat as an example, first weigh 100kg raw meat, which is convenient for batching later; then weigh 2.5kg of salt and sprinkle it evenly on the surface of the raw meat; Sodium nitrite, and then sprinkle evenly on the surface of the raw meat. Next, put the raw meat that has been sprinkled with salt and sodium nitrite on the tumbler, keep at 4°C for tumbling and marinati...

Embodiment 2

[0018] Example 2 In order to ensure that it meets the national food oxidation value standard and can prepare bacon with good export taste under the condition of low salt, one of the embodiments of the present invention is as follows. The method for making bacon specifically includes the following steps. First, the raw material Freeze the meat at minus 5°C for 2 hours, which will make it easier to cut the meat. If the freezing time is too short or too long, it will affect the cutting and shaping of the meat; after the meat is frozen, take it out and cut it into strips, and then Take the preparation of 100kg of raw meat as an example, first weigh 100kg of raw meat for later batching; then weigh 2.5kg of salt and sprinkle it evenly on the surface of the raw meat; then weigh 0.008kg of sub Sodium nitrate, and then sprinkle evenly on the surface of the raw meat. Next, put the raw meat that has been sprinkled with salt and sodium nitrite on the tumbler, keep at 6°C for tumbling and ...

Embodiment 3

[0019] Example 3 In order to ensure that it meets the national food oxidation value standard and can prepare bacon with good export taste under the condition of low salt, one of the embodiments of the present invention is as follows. The method for making bacon specifically includes the following steps. First, the raw material Freeze the meat at minus 5°C for 2 hours, which will make it easier to cut the meat. If the freezing time is too short or too long, it will affect the cutting and shaping of the meat; after the meat is frozen, take it out and cut it into strips, and then Take the preparation of 100kg of raw meat as an example, first weigh 100kg of raw meat for later batching; then weigh 2.5kg of salt and sprinkle it evenly on the surface of the raw meat; then weigh 0.008kg of sub Sodium nitrate, and then sprinkle evenly on the surface of the raw meat. Then put the raw meat that has been sprinkled with salt and sodium nitrite on the tumbler, keep it at 10°C for tumbling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com