Microwave vacuum preservation method for grains

A fresh-keeping method, microwave vacuum technology, applied in the application field of grain storage and fresh-keeping, can solve the problems of long cooling time, secondary pollution, etc., achieve high production efficiency, fast cooling speed, and facilitate continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 invention process example

[0024] Take rice microwave vacuum packaging preservation as an example. 2kg of newly processed rice is packed into a packaging bag with an opening on one side, and the specification is 30cm × 20cm. One of the side openings is 20cm wide, and the other three sides are sealed. The packaging bag material is polyester and polypropylene composite plastics. The first step is to seal with a heat sealing machine. When sealing, place a high-temperature-resistant comb-shaped mold between the upper and lower layers of the opening of the packaging bag. Remove the mold to make the packaging bag not completely closed. Leave a 1mm-diameter mold every 1cm. A total of 18 vents are reserved; the second step is to put the bag containing the grain in the microwave oven (produced by Nanjing Benhe Microwave Technology Development Co., Ltd., Jiangsu Province, PLC controlled intelligent microwave oven), at 0.17kW / kg Under the power of microwave irradiat...

Embodiment 2

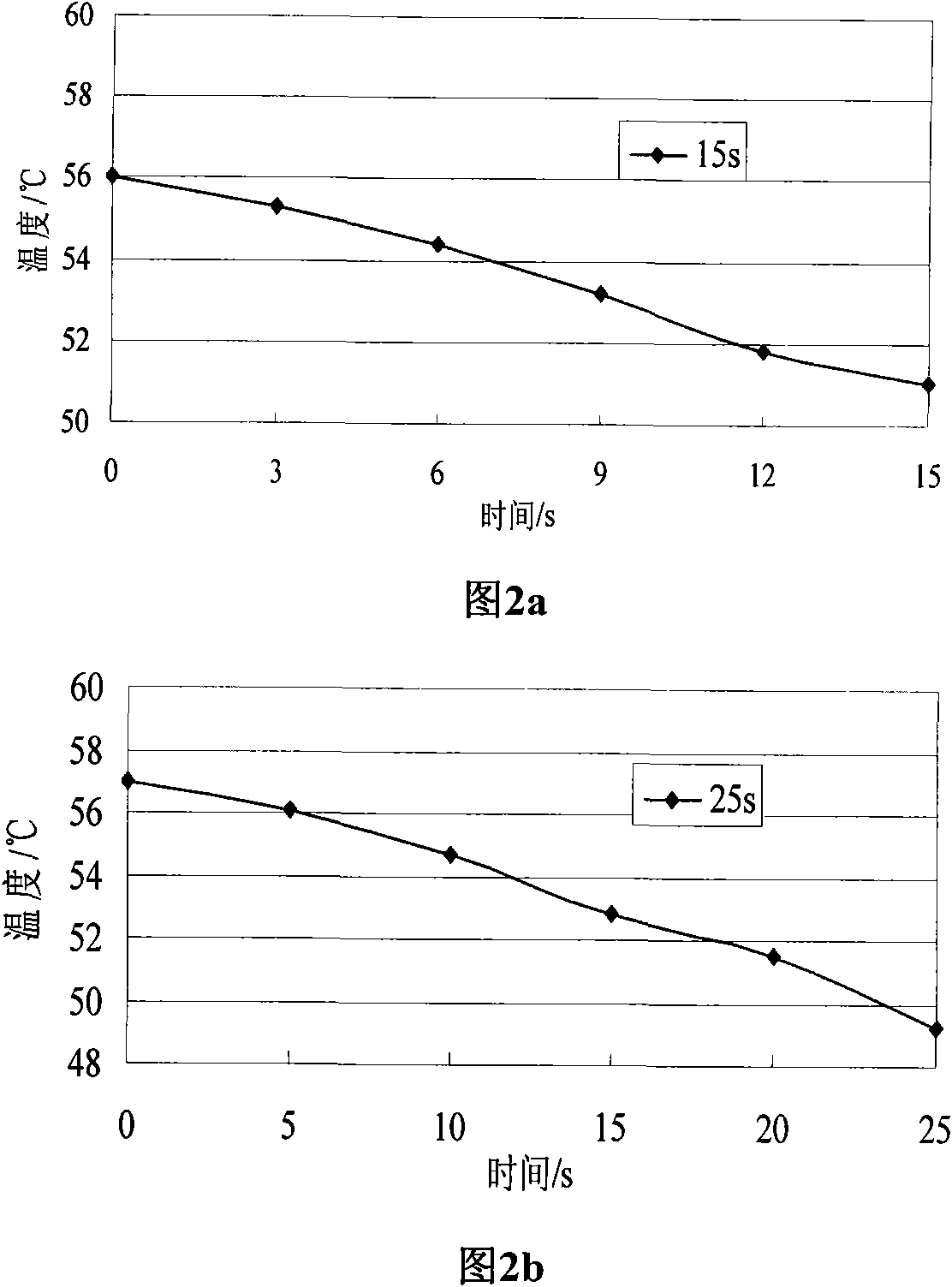

[0025] Embodiment 2 Vacuum cooling effect example

[0026] Take rice microwave vacuum packaging preservation as an example. Complete the microwave vacuum fresh-keeping process of rice according to the method in Example 1, only change the vacuuming time, and compare the cooling effect of different vacuuming time on microwave irradiation rice. See Table 1.

[0027] The cooling effect (raw material: rice) of different vacuum pumping time of the present invention of table 1

[0028] Vacuum time (s)

Embodiment 3

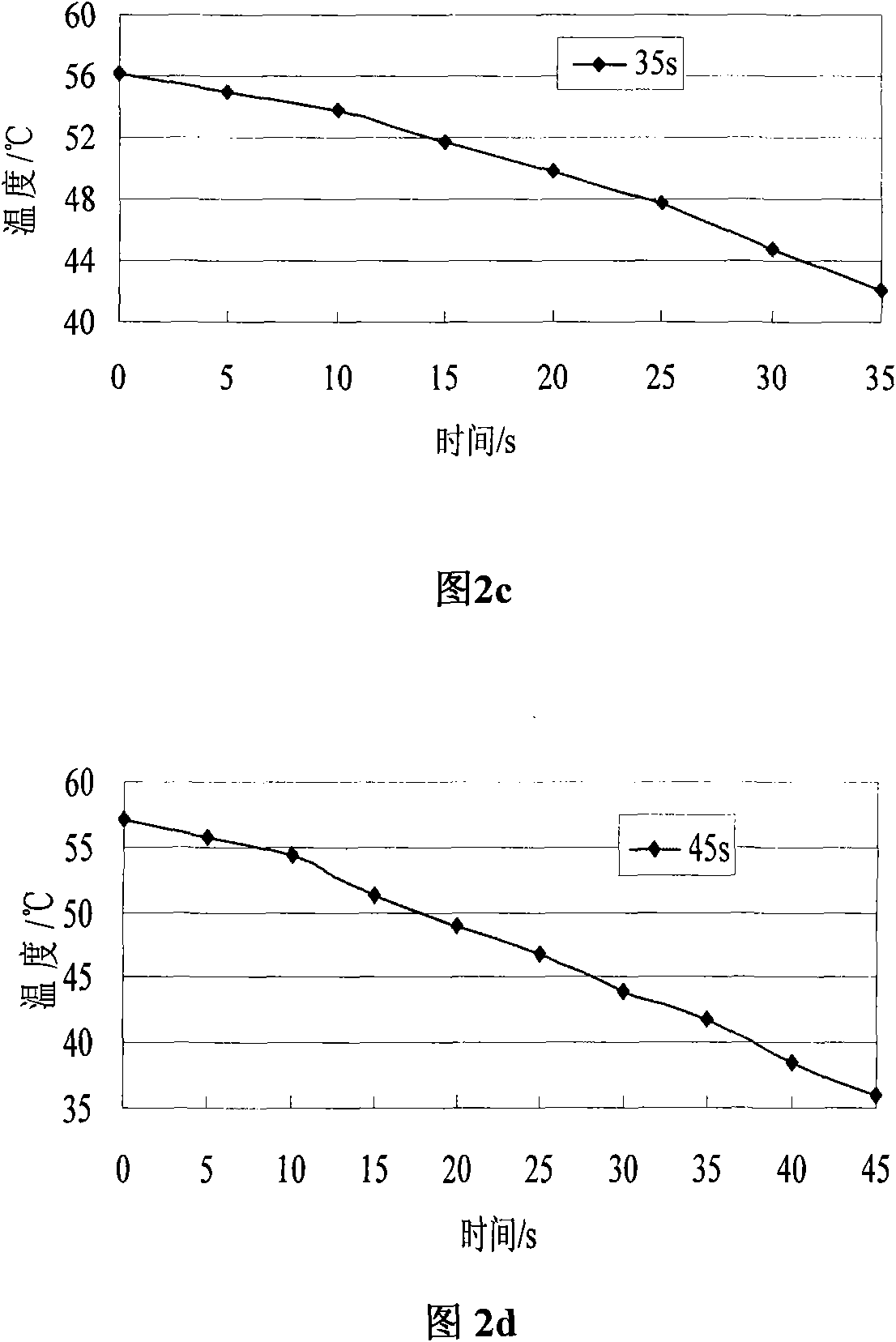

[0029] Example 3 Microwave Vacuum Preservation Effect Example

[0030] Take rice microwave vacuum packaging preservation as an example. This example is completed according to the method in Example 1. The results showed that there was no significant change in the appearance and nutritional components of rice after microwave irradiation treatment and vacuum packaging treatment. After three months of storage, the water loss of the rice was small, and the appearance quality, nutritional components and rice flavor had no obvious changes. Table 2 shows the microwave vacuum preservation effect of rice.

[0031] Microwave vacuum preservation effect of the present invention (raw material: rice) of table 2

[0032]

[0033]

[0034] Note: No. 1 is microwave + vacuum treated rice; No. 2 is control, untreated rice; No. 3 is rice stored for three months after microwave + vacuum treatment; No. 4 is control, untreated rice stored for three months Rice: 10 points for each sensory scor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com