Comprehensive utilization process of rutile middlings

A rutile and process technology, applied in the direction of silicon compounds, non-metallic elements, inorganic chemistry, etc., can solve the problems of failure to obtain sorting indicators, waste of valuable resources, low efficiency, etc., to improve comprehensive utilization rate and recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

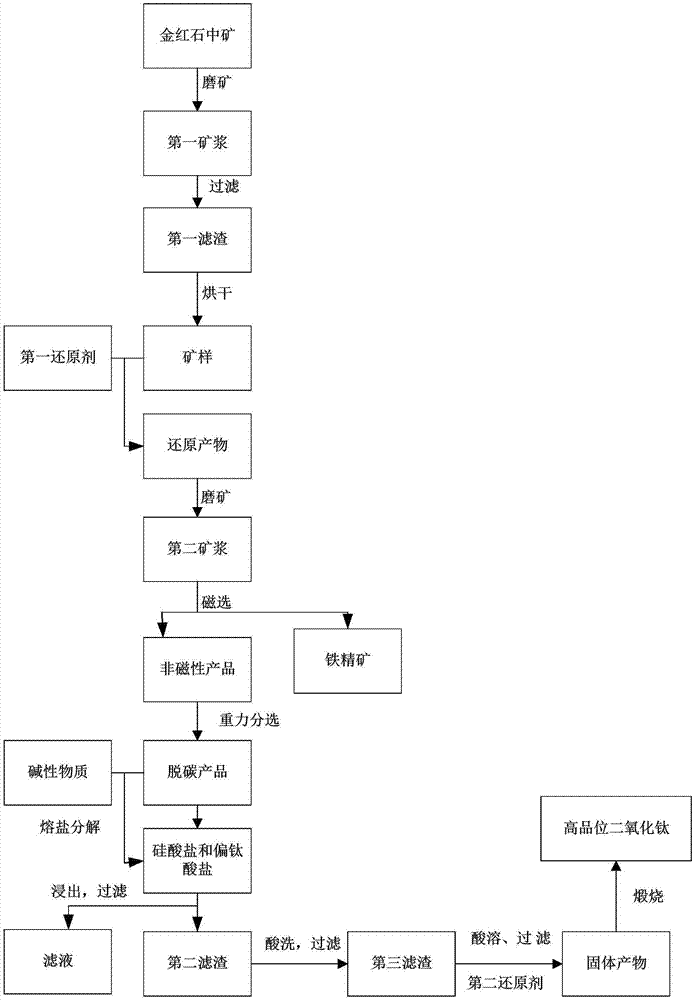

[0028] Please refer to figure 1 , the embodiment of the present invention provides a kind of rutile middling comprehensive utilization process, comprises the following steps:

[0029] (1) Grinding the middle ore of rutile until the particle size is -0.037mm has an occupancy rate of 85% to 90%, and the first pulp is obtained after classification; ore grinding is a technical means well known to those skilled in the art. The ore grinding equipment can be wet grinding or dry grinding, which is not particularly limited in this application.

[0030] (2) Filter the first pulp to obtain a first filter residue, and then dry the first filter residue to obtain an ore sample.

[0031] (3) Add the first reducing agent to the ore sample. After the ore sample is mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com