Novel sludge treatment device

A sludge treatment and equipment technology, applied in water/sludge/sewage treatment, sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, etc., can solve the uneven dehydration effect and the sludge dehydration effect Unsatisfactory, unstable pressure and other problems, to achieve the effect of preventing uneven dehydration effect, improving and balancing dehydration effect, and reducing the probability of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

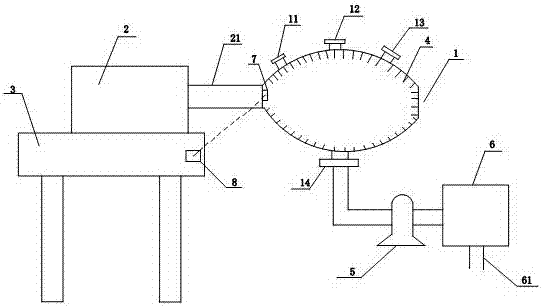

[0013] Such as figure 1 As shown, the present invention provides a new type of sludge treatment equipment, including a reaction body 1 provided with a steam inlet 11 and a sludge discharge port 14, the reaction body 1 is connected to the rotating shaft 21 of the rotating motor 2, and the rotating The motor 2 is located on the support platform 3, the reaction body 1 is also provided with a compressed gas inlet 12, the inner wall of the reaction body 1 is provided with a number of uniformly arranged cutting pieces 4, and the sludge discharge port 14 passes through The sludge pump 5 is connected to a high temperature constant temperature box 6, the bottom of the high temperature constant temperature box 6 is provided with a mud outlet 61, the inner wall of the reaction body 1 is provided with a temperature sensor 7, and the support platform 3 is equipped with and The temperature sensor 7 matches the temperature receiving display 8, and the reaction body 1 is also provided with a ...

Embodiment 2

[0015] Such as figure 1 As shown, after the sludge to be dehydrated is located in the reaction body 1, hot water vapor and compressed gas are introduced through the steam inlet 11 and the compressed gas inlet 12 respectively, so that the hot water vapor can be evenly distributed in the reaction body 1, then start the rotating motor 2, and the rotating shaft 21 drives the reaction body 1 to start rotating. When the reaction body 1 is rotating, the cutting piece 4 can break up the blocky sludge, increasing the overall contact area between the sludge and hot water vapor , the dehydration efficiency is improved, and the dehydration effect is improved. When the dehydration is completed, the sludge discharge port 14 is opened, and the sludge pump 5 is started. The sludge in the reaction body 1 enters the high-temperature thermostat 6 through the sludge pump 5, and the high-temperature The temperature of the incubator 6 is set at 300° C., and the sludge is discharged through the slud...

Embodiment 3

[0017] Set the specified temperature range for sludge dehydration to 70~90°C. During the dehydration process, once the temperature of the reaction body 1 detected by the temperature sensor 7 exceeds 90°C, the cooling air inlet 13 is opened to flow into the reaction body 1. Pass in cooling air, stop passing in cooling air after the temperature drops to within the specified temperature range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com