Carbon nano paper and its preparation method and application

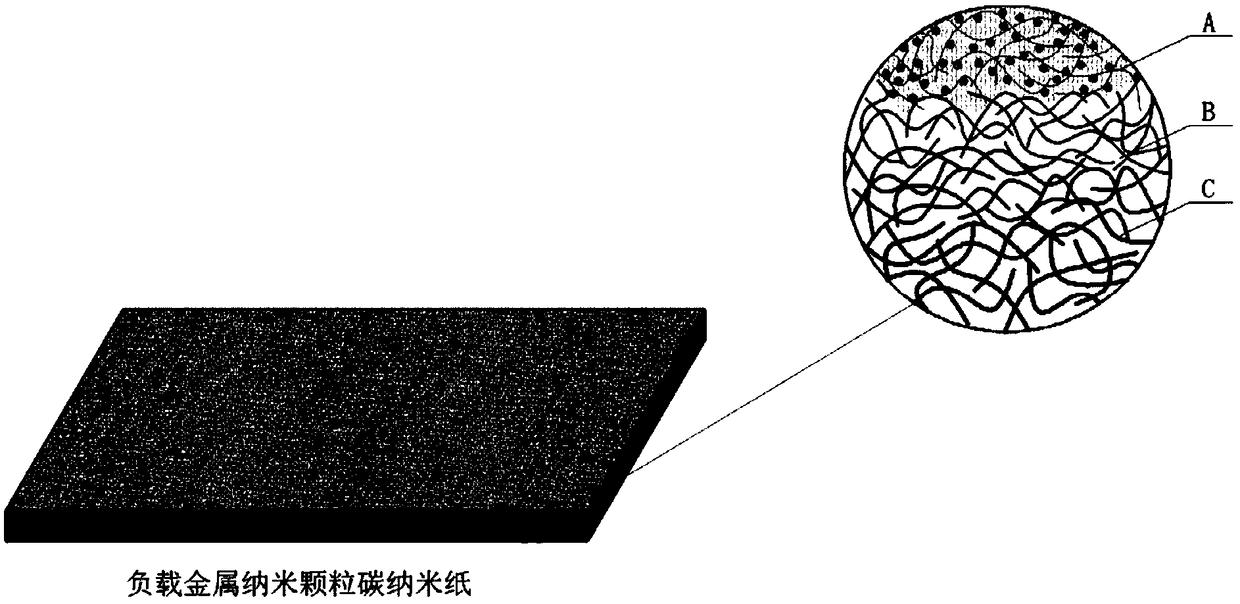

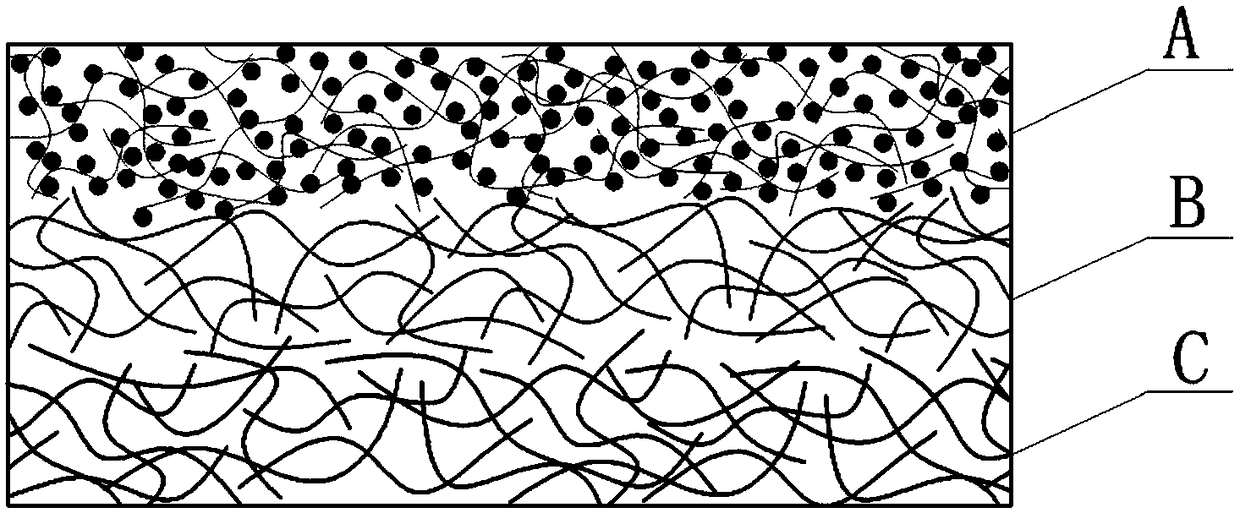

A carbon nanopaper, carbon nanotube technology, applied in papermaking, textiles and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve the problems of unsatisfactory air permeability and conductivity of composite materials, and achieve structural Good properties, excellent electrical conductivity and breathability, the effect of optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

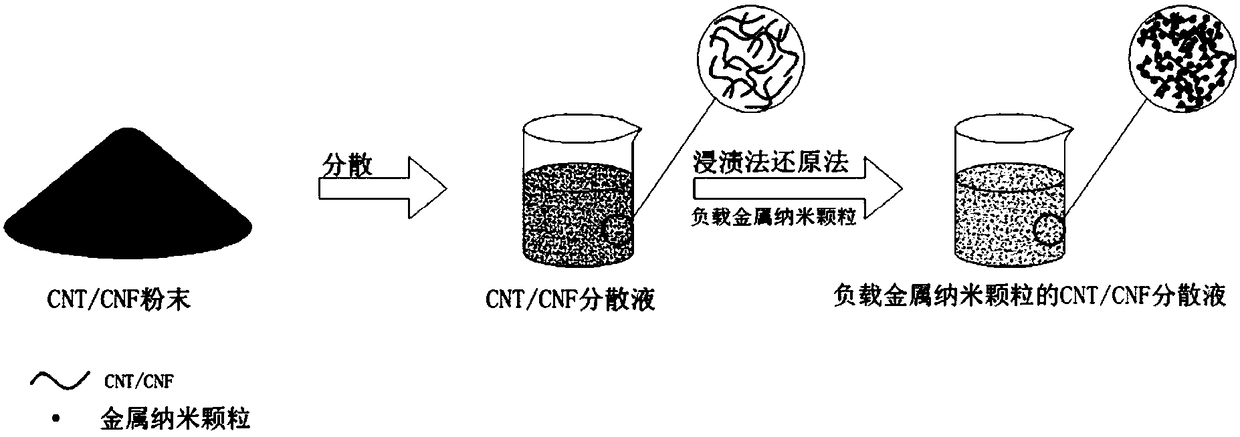

[0041] The present embodiment is a kind of carbon nano paper, and its preparation method is as follows:

[0042] (1) carbon nanotubes and surfactants with a diameter of 10-30nm are added into water at a mass ratio of 1:2, and No. 1 dispersion liquid 400ml is obtained through dispersion;

[0043]Add carbon nanotubes and surfactants with a diameter of 50-100nm into water at a mass ratio of 1:1.8, and disperse to obtain 200ml of No. 2 dispersion;

[0044] Add carbon nanofibers with a diameter of 200-600nm and a surfactant into water at a mass ratio of 1:1.5, and disperse to obtain 200ml of No. 3 dispersion;

[0045] Wherein, the mass ratio of carbon nanomaterials in No. 1, No. 2, and No. 3 dispersions is: 2:1:1;

[0046] (2) Under the condition of a temperature of 20-30°C, the Pt salt precursor solution (H 2 PtCl 6 aqueous solution) and added to No. 1 dispersion liquid, the addition amount is 100mL, after stirring for 20min, add NaOH to adjust the pH value of the mixed liquid>...

Embodiment 2

[0052] A kind of carbon nano paper of present embodiment, its preparation method is as follows

[0053] (1) carbon nanotubes and surfactants with a diameter of 10-30nm are added into water at a mass ratio of 1:1.8, and No. 1 dispersion liquid 300ml is obtained through dispersion;

[0054] Add carbon nanotubes with a diameter of 50-100nm and a surfactant into water at a mass ratio of 1:1.6, and disperse to obtain 200ml of No. 2 dispersion;

[0055] Add carbon nanofibers with a diameter of 200-600nm and a surfactant into water at a mass ratio of 1:1.2, and disperse to obtain 200ml of No. 3 dispersion;

[0056] Wherein, the mass ratio of carbon nanomaterials in No. 1, No. 2 and No. 3 dispersions is: 3:2:2;

[0057] (2) Prepare the Ag salt precursor solution (AgNO 3 aqueous solution) and added to No. 1 dispersion liquid, the addition amount is 100mL, after stirring for 60min, add NaOH to adjust the pH value of the mixed liquid>8; Reducing agent NaBH 4 , stirring for 10-30min, ...

Embodiment 3

[0063] This embodiment is a kind of carbon nano paper, the preparation method of which is the same as that of embodiment 1, the difference is that: it only includes two layers of carbon nano material structure, and the carbon nano tube layer with a diameter of 50-100 nm is not prepared.

[0064] The resistivity of the carbon nanopaper was tested by a four-probe resistance tester, and its resistivity was about 26.3mΩ.cm; its thickness was measured by a thickness tester to be 62 μm; the gas permeability test was carried out by a Schober air permeability tester, Its air permeability is 3.2μm / Pa.S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com