Solid-state atomic spin sensing structure surface stress noise ultra high precision test system

A technology of atomic spin and structural surface, applied in the field of quantum sensing, which can solve the problems of unstable output signal of transmitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

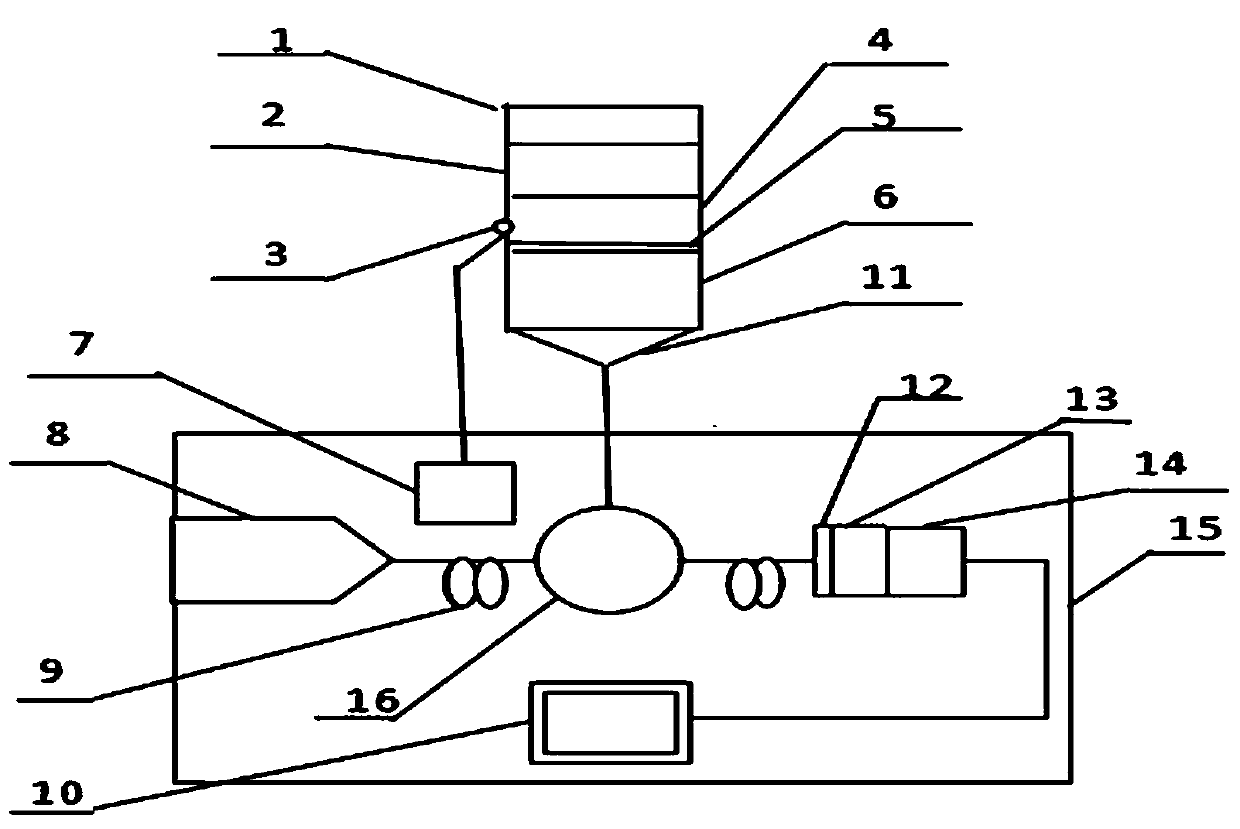

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] An ultra-high-precision test system for surface stress noise of a solid-state atomic spin sensing structure, including a 532nm laser, a microwave source, a coupler, a photodetector, a signal modulator, and a pressure display.

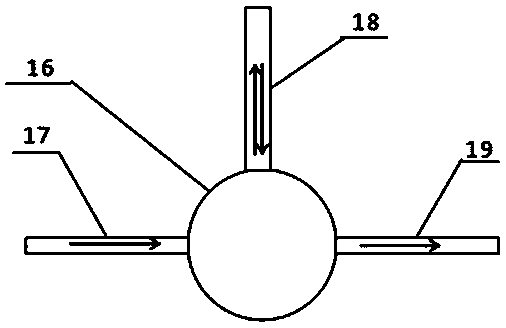

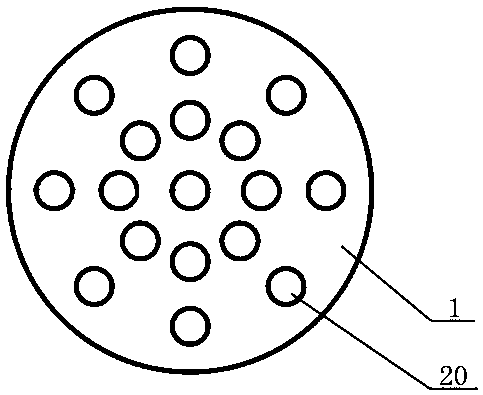

[0018] The specific connection relationship is as figure 1 As shown, the pressure sensor includes a pressure probe, and the pressure probe includes a diamond substrate 6, and the middle part of the upper surface of the diamond substrate 6 is processed with a diamond NV color center waveguide, and the diamond NV color center waveguide has a thickness of 200 microns and a diameter of 200 μm. Micron. A 200nm-thick diamond refractive index matching layer covering the NV color center waveguide is grown on the upper surface of the diamond substrate 6 as a reflective film 5 to reflect the fluorescence generated by exci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com