Intelligent large-power rectification equipment monitoring and control system

A technology of rectification equipment and control system, which is applied in the field of control, can solve problems such as low stability and reliability, series current fluctuations, and reduced current efficiency, and achieve high peripheral integration, high precision, and improved stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. In addition, those skilled in the art can make corresponding combinations of features in the embodiments in this document and in different embodiments according to the descriptions in this document.

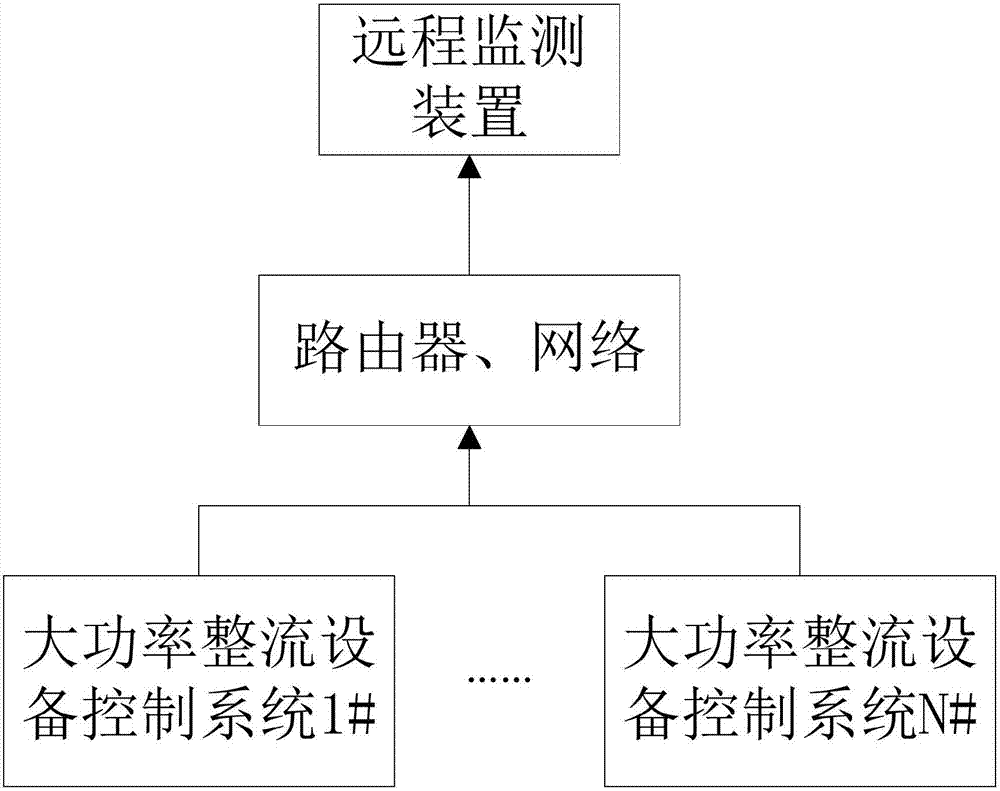

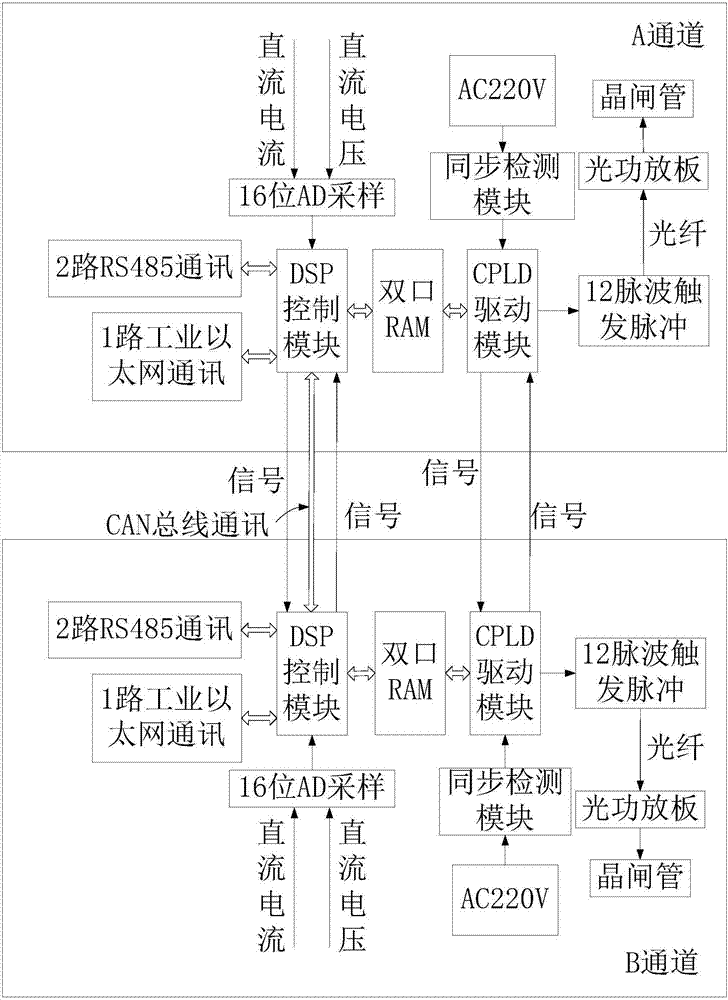

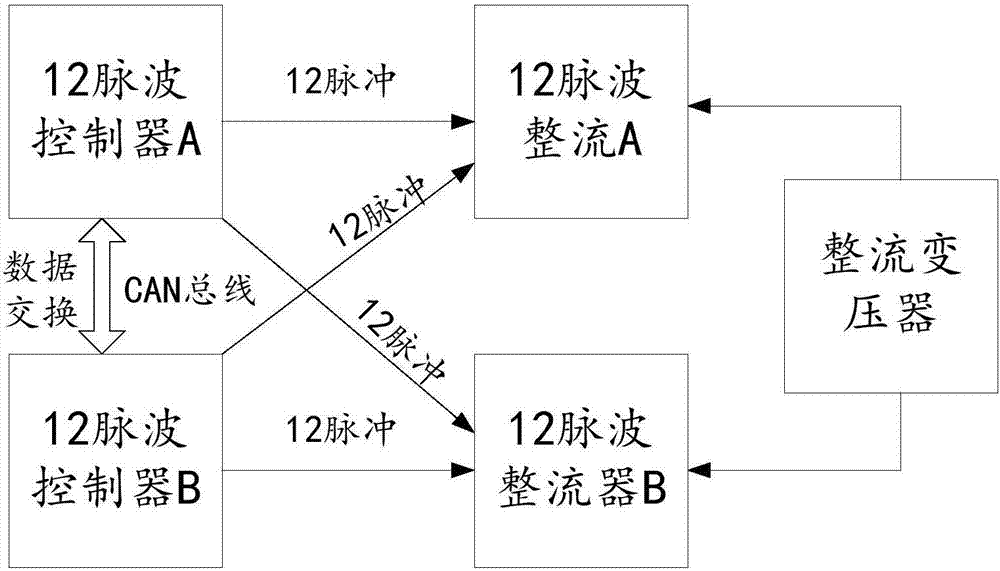

[0044] Intelligent high-power rectification equipment monitoring and control system described in the present invention, such as Figure 1 to Figure 4 As shown, an intelligent high-power rectification equipment monitoring and control system includes a remote monitoring device and a high-power rectification equipment control system, and the remote monitoring device is remotely connected to multiple high-power rectification equipment control systems through a router and a network . Such as figure 2 As shown, the high-powe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap