Preparation method of hydrophobic low-density shaddock peel carbon aerogel and application thereof

A technology of carbon aerogel and pomelo peel, which is applied in the field of material preparation and pollutant treatment, can solve the problems of expensive raw materials, incapable of large-scale industrial production, complicated and cumbersome preparation process, etc., and achieve environmental pollution relief, excellent hydrophobicity, The effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

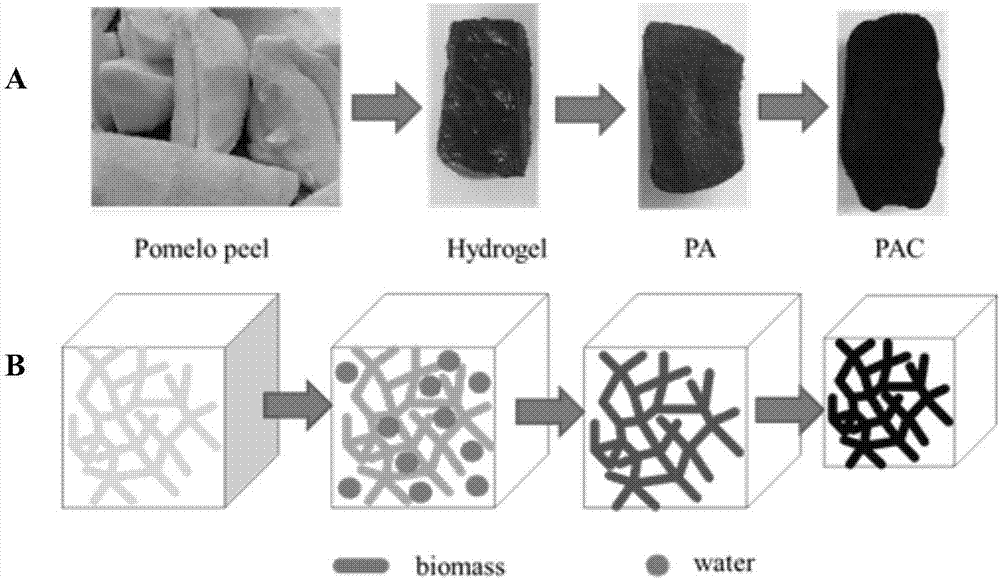

[0030] 1. Preparation of Hydrophobic Low-Density Grapefruit Peel Carbon Airgel

[0031] (1) Take the pomelo peel from which the outer skin and pulp have been removed, cut it into blocks of appropriate size, put it into an autoclave, and react at 180° C. for 24 hours to obtain the pomelo peel hydrogel.

[0032] (2) Transfer the grapefruit peel hydrogel into a large beaker filled with deionized water, and magnetically stir it in a constant temperature water bath at 40°C for 12 hours at a stirring speed of 200rpm, repeating 3 times.

[0033] (3) Freeze-drying the removed grapefruit peel hydrogel to obtain grapefruit peel aerogel. The obtained pomelo peel airgel was placed in a tube furnace at 900 °C and calcined under nitrogen for 60 min at a nitrogen flow rate of 50 mL min -1 , the heating rate is 3°C min -1 , after cooling to room temperature, a hydrophobic and low-density grapefruit peel carbon aerogel was obtained.

[0034] 2. Quantitative adsorption experiment

[0035] T...

Embodiment 2

[0037] 1. Preparation of Hydrophobic Low-Density Grapefruit Peel Carbon Airgel

[0038] (1) Take the pomelo peel from which the outer skin and pulp have been removed, cut it into blocks of suitable size, put it into an autoclave, and react at 200° C. for 12 hours to obtain the pomelo peel hydrogel.

[0039] (2) Transfer the grapefruit peel hydrogel into a large beaker filled with deionized water, and magnetically stir it in a constant temperature water bath at 60°C for 8 hours at a stirring speed of 100 rpm, and repeat 6 times.

[0040] (3) Freeze-drying the removed grapefruit peel hydrogel to obtain grapefruit peel aerogel. The obtained pomelo peel airgel was placed in a tube furnace at 800 °C and calcined under nitrogen for 120 min at a nitrogen flow rate of 50 mL min -1 , the heating rate is 3°C min -1 , after cooling to room temperature, a hydrophobic and low-density grapefruit peel carbon aerogel was obtained.

[0041] 2. Quantitative adsorption experiment

[0042] Ta...

Embodiment 3

[0044] 1. Preparation of Hydrophobic Low-Density Grapefruit Peel Carbon Airgel

[0045] (1) Take the pomelo peel from which the outer skin and pulp have been removed, cut it into blocks of suitable size, move it into an autoclave, and react at 150° C. for 24 hours to obtain the pomelo peel hydrogel.

[0046] (2) Transfer the grapefruit peel hydrogel into a large beaker filled with deionized water, and magnetically stir it in a constant temperature water bath at 20°C for 6 hours at a stirring speed of 1000rpm, repeating 12 times.

[0047] (3) Freeze-drying the removed grapefruit peel hydrogel to obtain grapefruit peel aerogel. The obtained pomelo peel aerogel was placed in a tube furnace at 950 °C and calcined under nitrogen for 30 min at a nitrogen flow rate of 50 mL min -1 , the heating rate is 3°C min -1 , after cooling to room temperature, a hydrophobic and low-density grapefruit peel carbon aerogel was obtained.

[0048] 2. Quantitative adsorption experiment

[0049] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com