Method for preparing granulate and sheetlike fluorescence labeling microplastics

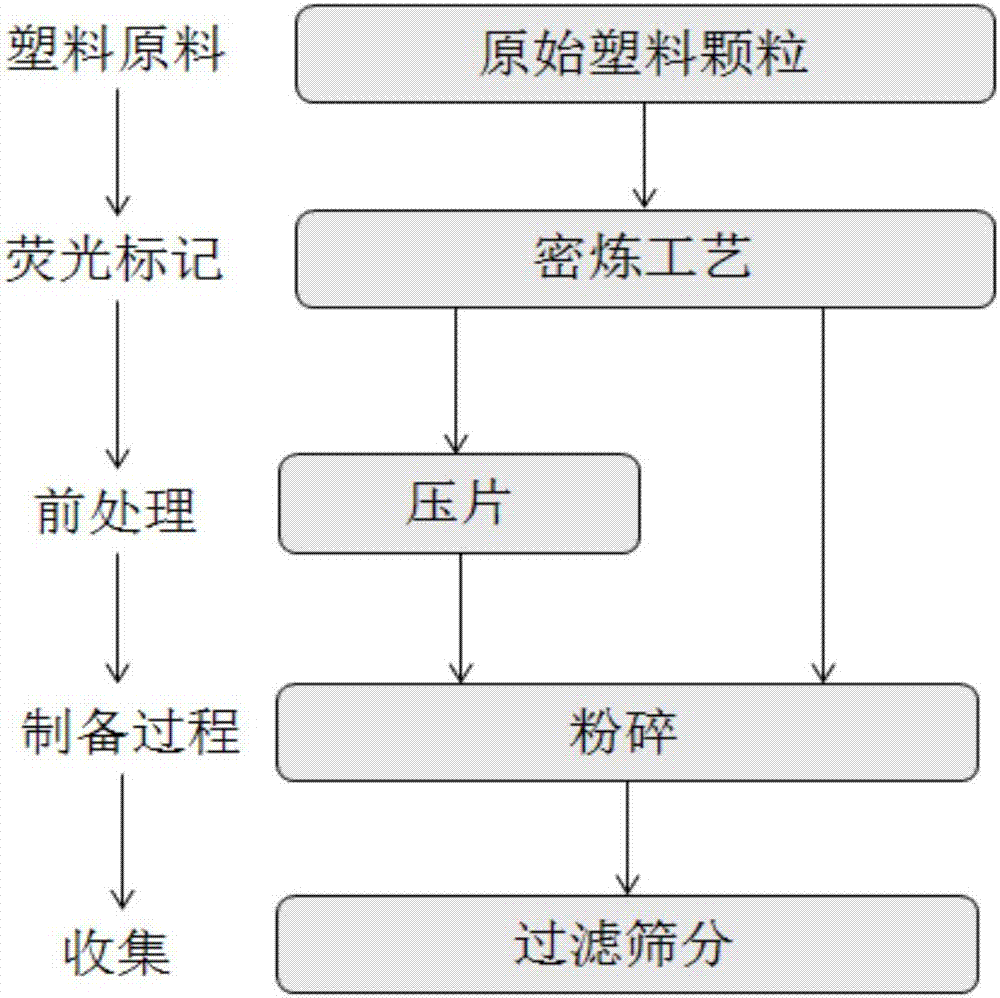

A technology for fluorescent labeling and microplastics, which is applied in the field of preparation of granular and flake fluorescent labeling microplastics. It can solve the problem that plastic microspheres with uniform shape cannot simulate microplastics well, and achieve uniform shape and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of polystyrene fluorescently labeled microplastics in the form of granules and flakes:

[0033] (1) Mix 48g of polystyrene particles with 1.92g of Thioindigo dye at one time, inject it into the feed port of the torque rheometer, set the temperature at 190°C, and set the time for 5min, and fluorescently label the polystyrene, the obtained Fluorescently labeled polystyrene, such as figure 2 shown;

[0034] (2) Take about 100 mg of fluorescently labeled polystyrene obtained in step (1) each time, place it on a flat vulcanizing machine for tableting, set the temperature at 180°C, and press at 5 MPa, and press it into a sheet with a thickness of 10 μm shaped plastics, such as image 3 shown;

[0035] (3) Use a high-speed pulverizer to pulverize the two kinds of fluorescently labeled polystyrene obtained in the above steps (1) and (2), pulverize 4 times, and pulverize each time for 5 minutes to obtain granular and flake polystyrene fluorescent polystyrene resp...

Embodiment 2

[0038] Preparation of granular and flake polyethylene fluorescently labeled microplastics:

[0039] (1) Mix 48g of polyethylene particles with 3.6g of Thioindigo dye at one time, inject it into the feed port of the torque rheometer, set the temperature at 180°C, and set the time for 6min to fluorescently label the polyethylene, and the resulting fluorescently labeled polyethylene;

[0040] (2) Take about 80 mg of the fluorescently labeled polyethylene obtained in step (1) each time, place it on a flat vulcanizing machine for tableting, set the temperature at 160 ° C, and press at 4 MPa, and press it into a sheet with a thickness of 8 μm plastic;

[0041] (3) Use a high-speed pulverizer to pulverize the two kinds of fluorescently labeled polyethylene obtained in the above steps (1) and (2), pulverize 3 times, and pulverize each time for 3 minutes to obtain granular and flake-shaped polyethylene fluorescent microplastics respectively .

[0042] (4) The two microplastics are w...

Embodiment 3

[0044] Preparation of fluorescently labeled polypropylene microplastics in the form of granules and flakes:

[0045](1) Mix 48g of polypropylene particles with 4.8g of Thioindigo dye at one time, inject it into the feeding port of the torque rheometer, set the temperature at 190°C, and the time is 8min, and carry out fluorescent labeling on polypropylene, and the obtained fluorescent labeling polypropylene;

[0046] (2) Take about 90 mg of fluorescently labeled polypropylene obtained in step (1) each time, place it on a flat vulcanizing machine for tableting, set the temperature at 180°C, and press at 3 MPa, and press it into a sheet with a thickness of 12 μm plastic;

[0047] (3) Use a high-speed pulverizer to pulverize the two fluorescently labeled polypropylenes obtained in the above steps (1) and (2), pulverize 5 times, and pulverize each time for 4 minutes to obtain granular and flake-shaped polypropylene fluorescent microplastics respectively .

[0048] (4) The two mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com