Hybrid power system and control method based on self-diagnosis electromagnetic jaw clutch

A technology of jaw clutches and hybrid power systems, applied in the direction of magnetic drive clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of vehicle dynamic performance disorder, strong electromagnetic interference, high dust and metal debris content, and achieve The effect of compact structure and mature structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

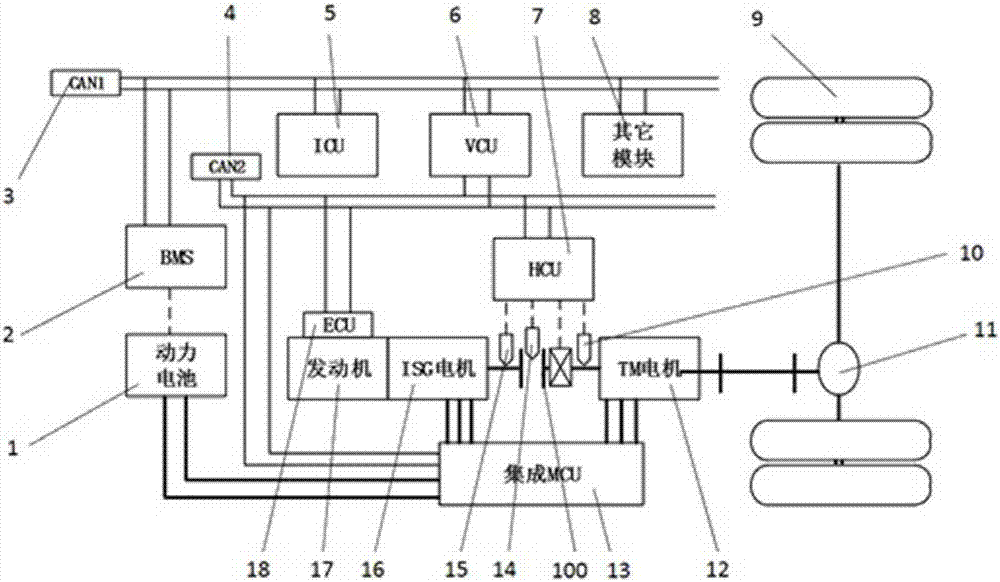

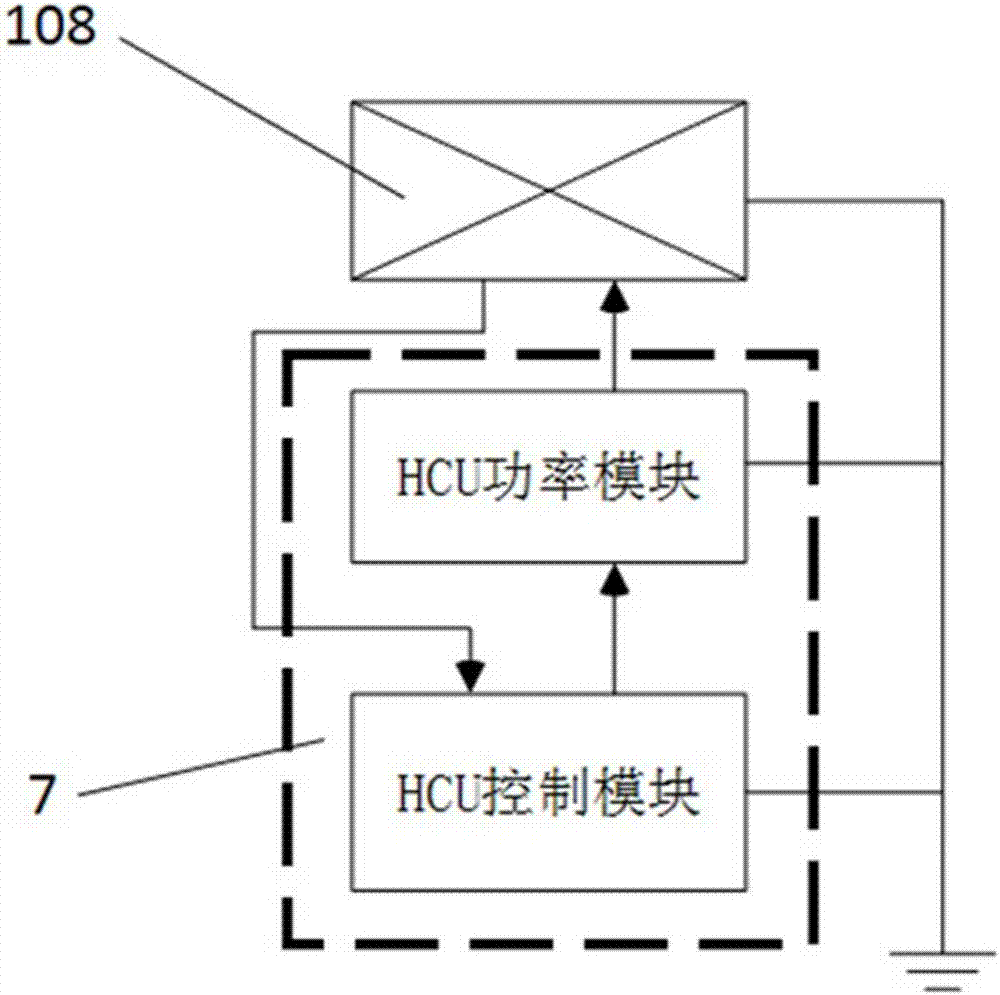

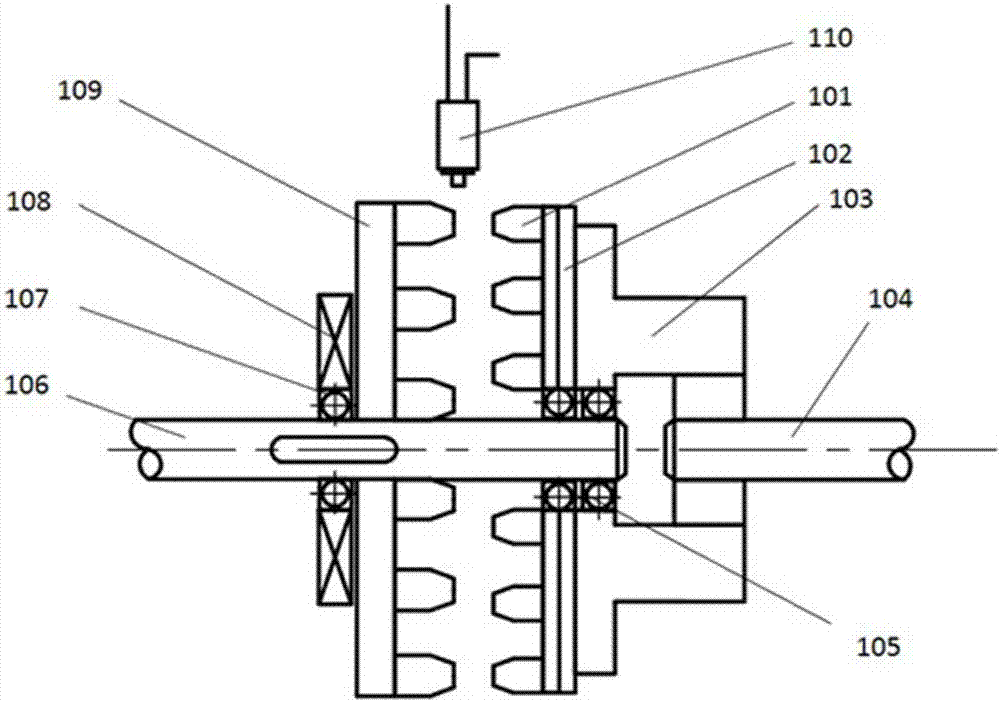

[0041] Combine below Figure 1-5 Describe in detail the technical solution of the hybrid power system based on the self-diagnosing electromagnetic jaw clutch:

[0042] A hybrid power system based on a self-diagnosing electromagnetic jaw clutch, including an engine 17, a power generation and starting integrated motor 16, a main drive motor 12 and a clutch assembly 100, the engine 17 is connected to the power generation and starting integrated motor 16, and the power generation and starting integrated motor 16 is connected with the main drive motor 12 through the clutch assembly 100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com