Preparation method of flower-like BiOCl photocatalyst, prepared BiOCl photocatalyst and application of BiOCl photocatalyst

A photocatalyst and flower-like technology, applied in the field of BiOCl photocatalyst, can solve the problems of high cost and cumbersome process, and achieve the effects of less energy consumption and simple and convenient steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

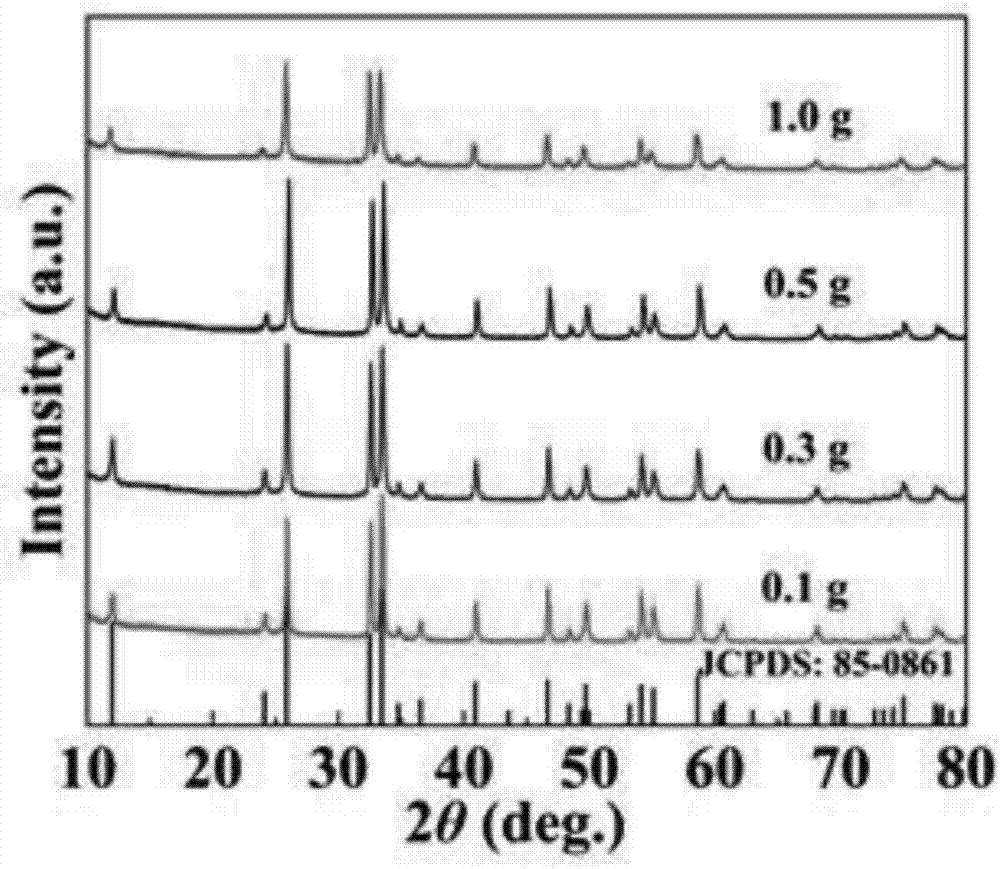

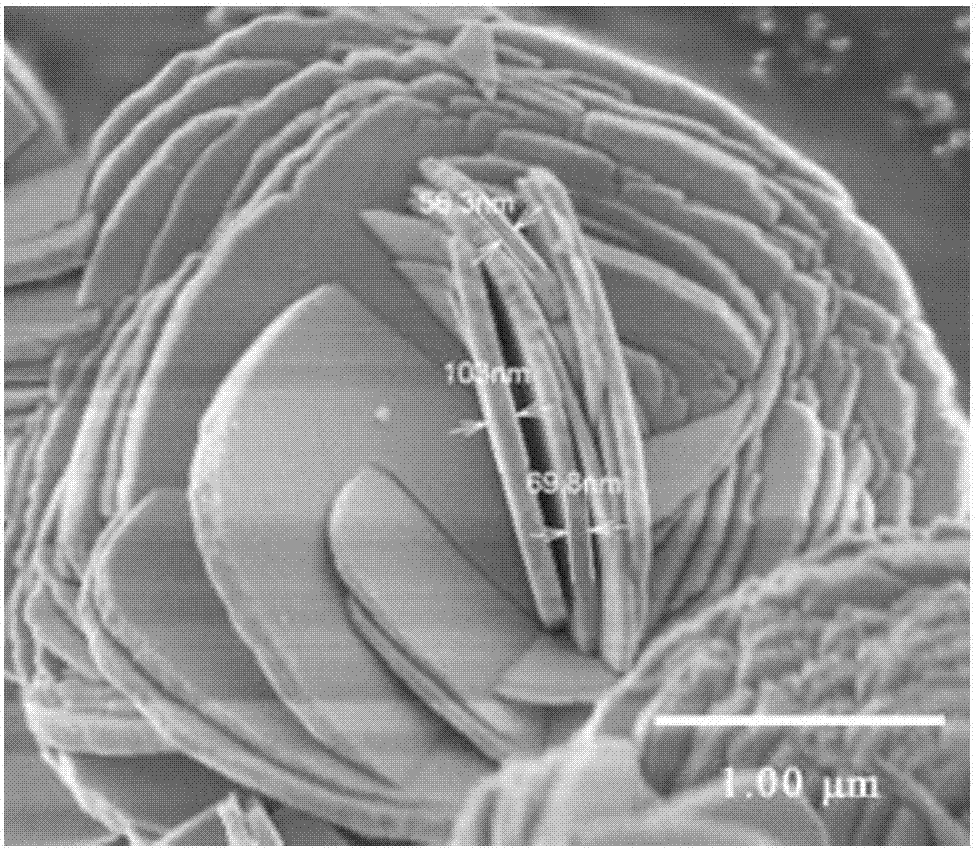

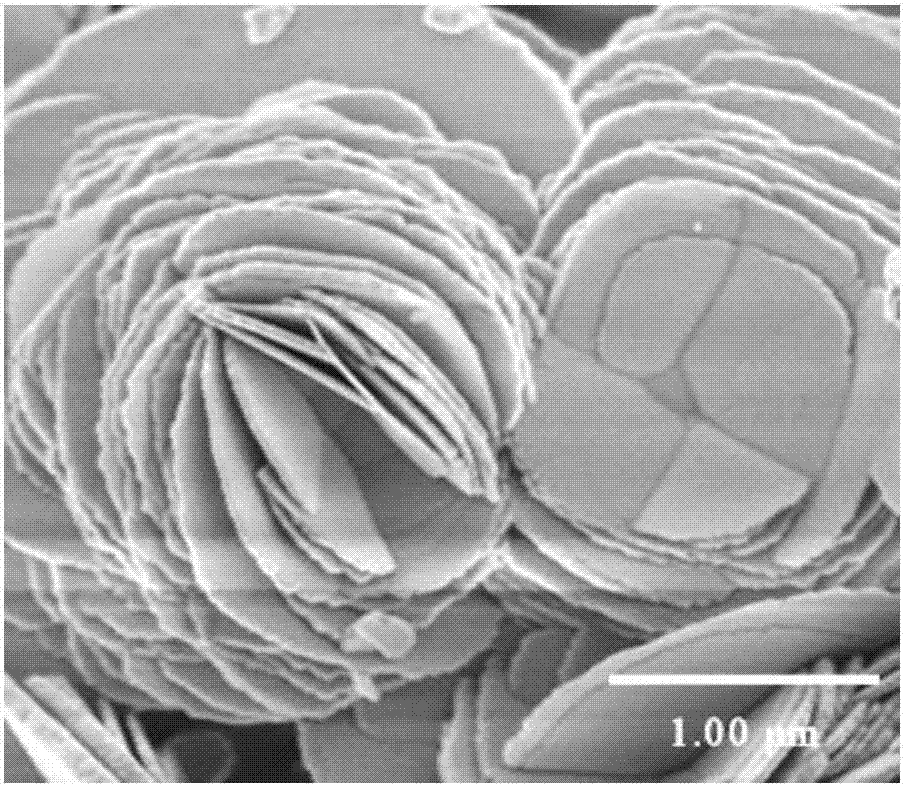

[0034] The preparation method of the flower-shaped BiOCl photocatalyst of the embodiment of the present invention, described method comprises the following steps:

[0035] (1) Add bismuth nitrate and maltose in ultrapure water, and drop chloride solution, stir to form bismuth precursor; The molar dosage ratio of described bismuth nitrate and maltose is: 1: (0.2-3);

[0036] (2) Adjust the pH value of the bismuth precursor to 5.0-6.5 with an alkaline solution to form a reactant;

[0037] (3) Reacting the reactant at 150-160°C for 24-30h to obtain a precipitate;

[0038] (4) Washing and drying the precipitate obtained in step (3) to obtain a BiOCl photocatalyst with a flower-like structure.

[0039] In the synthesis process, bismuth source generally selects bismuth nitrate, such as commercially available Bi(NO 3 ) 3 ·5H 2 O, bismuth nitrate decomposes into basic salt in water. The chloride is easily soluble in water, and it is prepared into a solution for subsequent use. T...

Embodiment 1

[0047] Use an electronic balance to weigh 0.48507g of bismuth nitrate pentahydrate and 0.5g of maltose in a beaker; prepare a potassium chloride solution with a concentration of 0.2mol / L and a potassium hydroxide solution with a concentration of 1mol / L; add 25mL of deionized water to the beaker water, and add 10mL of 0.2mol / L potassium chloride solution dropwise, and stir while adding dropwise. After the dropwise addition, continue to stir at room temperature for 0.5h to form a certain concentration of bismuth precursor; The precursor was transferred to the inner lining of the reactor and continued to stir at room temperature; the pH of the bismuth precursor was adjusted to 6.0 with the prepared potassium hydroxide solution; Thermal reaction to obtain a precipitate; wash the precipitate with ultrapure water until clarified, then with absolute ethanol until clarified, put it in a vacuum drying oven, and dry it at 40°C to obtain the target product BiOCl.

Embodiment 2

[0049] Use an electronic balance to weigh 0.48507g of bismuth nitrate pentahydrate and 0.1g of maltose in a beaker; prepare a potassium chloride solution with a concentration of 0.2mol / L and a potassium hydroxide solution of 1mol / L; add 25mL of deionized water to the beaker water, and add 10mL of 0.2mol / L potassium chloride solution dropwise, and stir while adding dropwise. After the dropwise addition, continue to stir at room temperature for 0.5h to form a certain concentration of bismuth precursor; The precursor was transferred to the inner lining of the reactor and continued to stir at room temperature; the pH of the bismuth precursor was adjusted to 6.0 with the prepared potassium hydroxide solution; Thermal reaction to obtain a precipitate; wash the precipitate with ultrapure water until clarified, then with absolute ethanol until clarified, put it in a vacuum drying oven, and dry it at 40°C to obtain the target product BiOCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com