Method and device for treating alkali-residue wastewater

A technology for alkali slag wastewater and treatment methods, which is applied in natural water treatment, water/sewage treatment, multi-stage water/sewage treatment, etc., and can solve problems such as high content of chemical oxygen demand in effluent, difficult biochemical treatment, high toxicity, etc. , to achieve the effects of reducing chemical oxygen demand, improving biodegradability, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

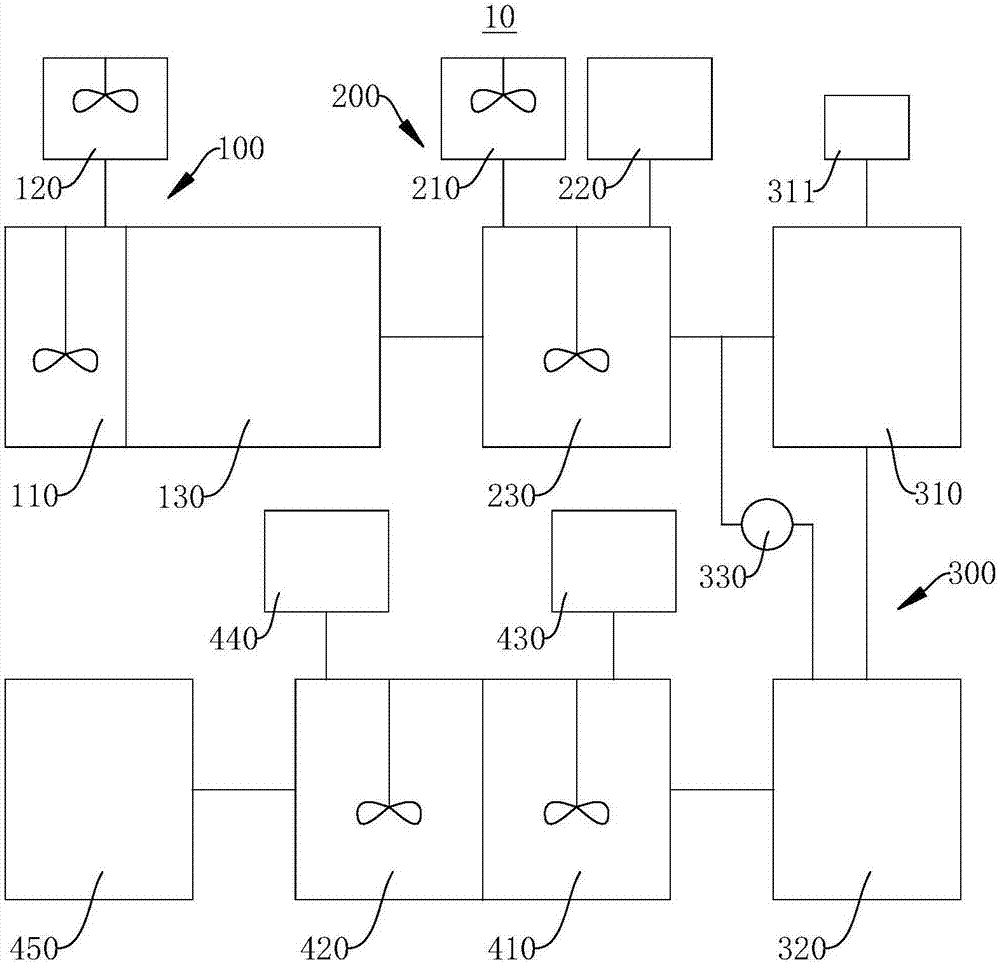

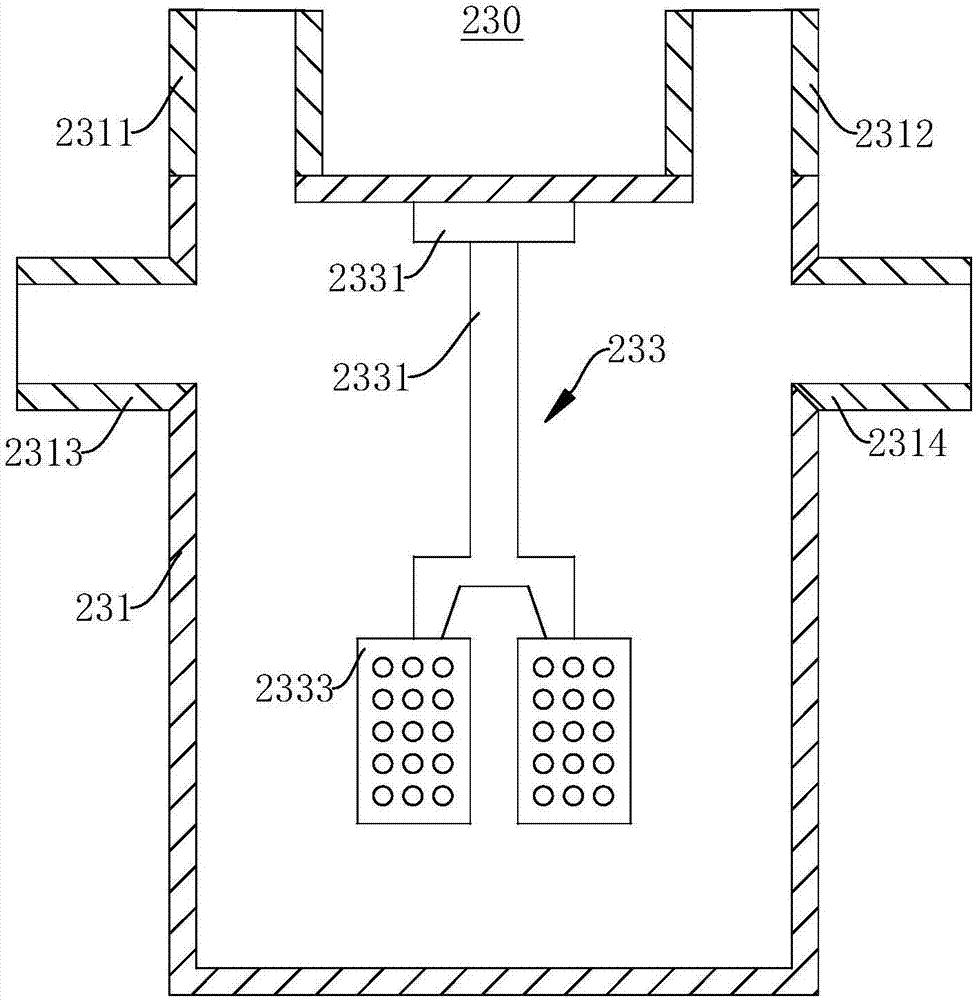

[0033] see figure 1 , this embodiment provides an alkali slag wastewater treatment device 10 for treating alkali slag neutralized water. The alkali slag wastewater treatment device 10 provided in this embodiment can effectively remove refractory organic matter in the alkali slag neutralization water, and improve the biodegradability of the alkali slag neutralization water. At the same time, the chemical oxygen demand in the treated alkali slag is significantly reduced, thereby eliminating the influence of the alkali slag neutralizing water on subsequent biochemistry.

[0034] The alkali slag wastewater treatment device 10 provided in this embodiment includes an acidification oil removal unit 100 , a pre-oxidation unit 200 , an electro-Fenton oxidation unit 300 and a solid-liquid separation unit 400 .

[0035] It can be understood that the acidizing deoiling unit 100 is used for deoiling the alkali slag and neutralized water. The pre-oxidation unit 200 is used to oxidize the ...

no. 2 example

[0055] see Figure 4 , This embodiment provides a method for treating alkali slag wastewater, which can effectively remove refractory organic matter in alkali slag neutralized water, and improve the biodegradability of alkali slag neutralized water. At the same time, the chemical oxygen demand in the treated alkali slag is significantly reduced, thereby eliminating the influence of the alkali slag neutralizing water on subsequent biochemistry.

[0056] The method for treating alkali slag wastewater provided in this embodiment includes: acidification degreasing step S1, pre-oxidation step S2, electro-Fenton oxidation step S3 and solid-liquid separation step S4, which will be described respectively below.

[0057] Acidification and deoiling step: perform demulsification and separation on the neutralized water of the alkali slag contained in the acidification tank 110 , and perform oil-water separation on the neutralized water of the alkali slag after demulsification and separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com