River mud treatment method

A technology of river silt and treatment method, applied in the field of water treatment, can solve the problem of large dosage of microbial inoculants, and achieve the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The microbial agent used in Example 1 and Example 2 is a microbial powder, which contains high-temperature bacteria, bacillus, saccharomyces and lactic acid bacteria, etc., and the concentration of bacteria in the powder is 10 9 cells / g~10 12 cells / g. The microbial agent used in Example 3 is a microbial solution, which contains high-temperature bacteria, bacillus, saccharomyces and lactic acid bacteria, etc., and the concentration of bacteria in this solution is 10 9 cells / mL~10 12 cells / mL.

[0041] Example 1

[0042] 1) Mix 1000L of untreated river silt with 2L of microbial powder and 30L of fallen garden leaves evenly, stack them on a platform with ventilation ducts at a height of 0.6m, and carry out aerobic fermentation. During the fermentation process, turn over once a day, After fermenting for 5 days, obtain the decomposed river mud for composting;

[0043] 2) First mix 10L of the above-mentioned compost with decomposed river silt, 10L of microbial powder, an...

Embodiment 2

[0049] 1), get the decomposed river silt after composting in 2000L embodiment 1, this silt is used as the decomposed river silt for composting in embodiment 2;

[0050] 2), 6000L of a certain river silt to be treated with a water content of 65% and 100L of the above-mentioned compost with decomposed river silt, 50L of microbial powder, and 750L of fallen garden leaves were mixed uniformly to obtain a mixture;

[0051] 3) Stack the above mixture in the natural drying yard, the shape of the pile is conical, and the height of the pile is 1.5m. Carry out aerobic fermentation. At the beginning, the temperature of the mixture continues to rise. After 4 hours of fermentation, the temperature rises to about 62°C. Then after continuing for 1 hour in this temperature range, the temperature began to drop. At this time, use a turning machine to turn the mixture. During the subsequent fermentation process, the temperature of the mixture repeats the above rule. Whenever the temperature of th...

Embodiment 3

[0056] 1) Mix 2000L of untreated river sludge with 40L of microbial solution and 300L of rice bran evenly, and stack them on a platform with ventilation ducts at a height of 0.8m for aerobic fermentation. Turn over and throw when beginning to descend, and after 15 days of fermentation, obtain decomposed river silt for composting;

[0057] 2), first mix 700L of decomposed river silt for composting, 200L of microbial solution, and 10500L of rice bran, add 80000L of a certain river silt to be treated with a moisture content of 70%, and mix to obtain a mixture;

[0058] 3) Stack the above mixture on a platform with ventilation ducts at a stacking height of 1.2m for aerobic fermentation. During the fermentation process, when the temperature of the fermented product starts to drop, turn it over and toss it. After 15 days of fermentation, it will be composted and decomposed River silt.

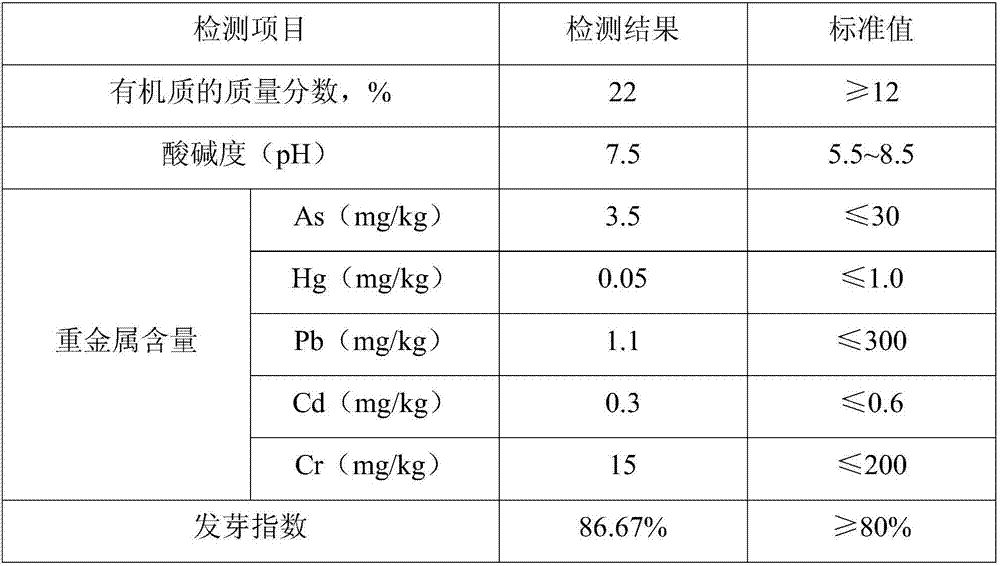

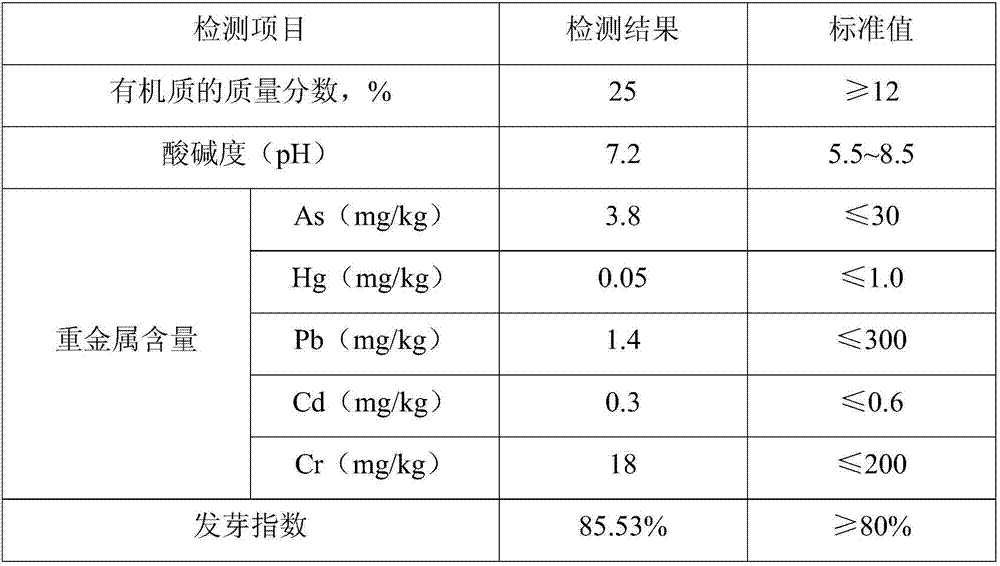

[0059] After composting, the decomposed river silt has a tan appearance, uniform particle distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com