A turning and throwing machine for the production of organic fertilizers and nutrient substrates

A technology of nutrient substrate and organic fertilizer, applied in the field of turning and throwing machines, can solve the problems of poor turning effect, unadjustable shape, prolonged fermentation time, etc., and achieve the effects of easy adjustment, strong adaptability, and even turning and throwing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

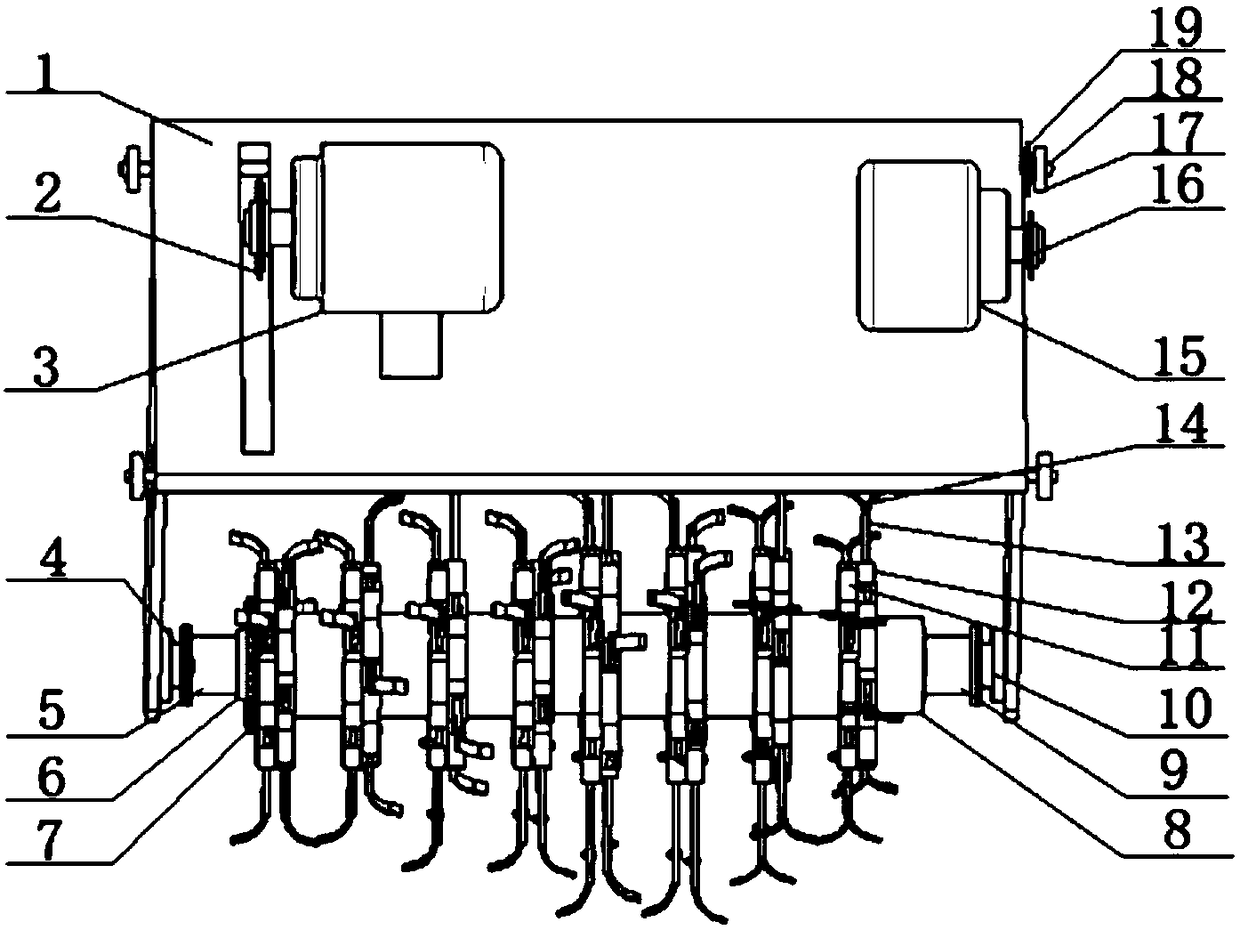

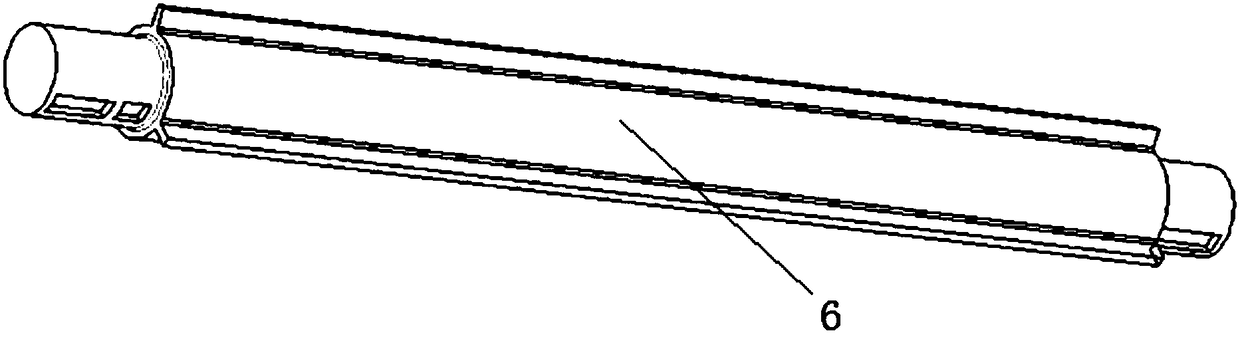

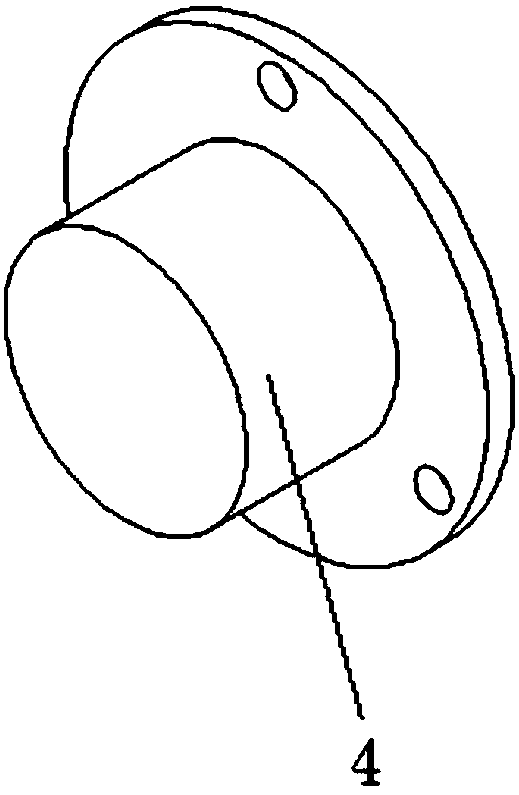

[0045] A turning and throwing machine for the production of organic fertilizers and nutrient substrates, see figure 1 , the turning machine includes frame 1, turning motor sprocket 2, turning motor 3, left support 4, left turning shaft sleeve 5, turning shaft 6, turning shaft sprocket 7, turning shaft Shaft sleeve 8, right turning and throwing shaft sleeve 9, right support 10, main turning and throwing cutter head 11, auxiliary turning and throwing cutter head 12, cutter shaft 13, cutter head 14, transmission motor 15, transmission motor sprocket 16, transmission Wheel 17, transmission shaft 18, transmission shaft sprocket 19, are provided with turning over and throwing motor 3 and transmission motor 15 on frame 1, are provided with turning over throwing mechanism horizontally in frame 1 inner bottom, are provided with in frame 1 right rear walking mechanism. The throwing mechanism is made up of turning and throwing shaft 6, main turning and throwing cutter head 11, auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com