Novel boiler main steam temperature regulating device and control method

A main steam temperature and boiler technology, which is applied in the field of new boiler main steam temperature adjustment devices, can solve problems such as thermal fatigue cracks, leakage of desuperheating water for regulating valve cage and valve core, impact of steam turbine blades, etc., so as to avoid thermal fatigue damage and ensure Stability, guaranteed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

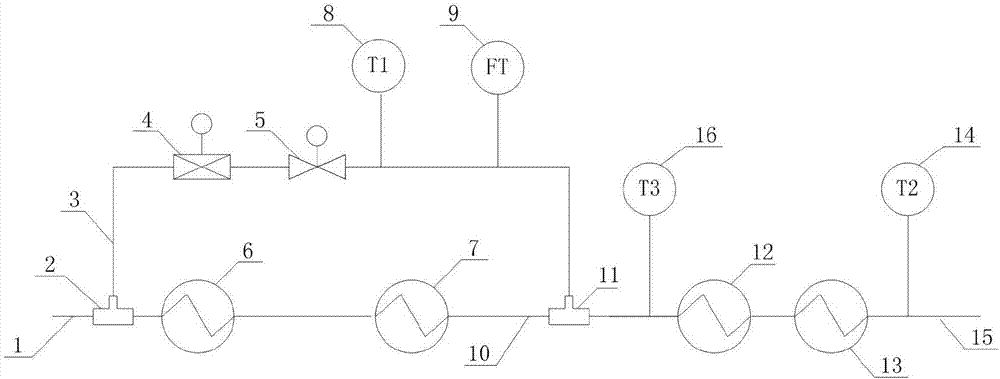

[0026] as attached figure 1 As shown, the new type boiler main steam temperature regulating device of this embodiment includes a series-connected primary superheater 6 and a panel superheater 7, one end of the primary superheater and the desuperheating steam pipeline and the front end of the primary superheater The steam pipelines are respectively connected, the panel superheater is connected with one end of the steam pipeline before the inlet tube group of the secondary superheater, and the other end of the steam pipeline before the inlet tube group of the secondary superheater is connected with the desuperheating steam pipeline One end of the two-stage superheater inlet tube group is respectively connected, the secondary superheater inlet tube group 12 is connected in series with the secondary superheater outlet tube group 13, and the secondary superheater outlet tube group is connected in series with the main steam pipeline 15;

[0027] The desuperheating steam pipeline is ...

Embodiment 2

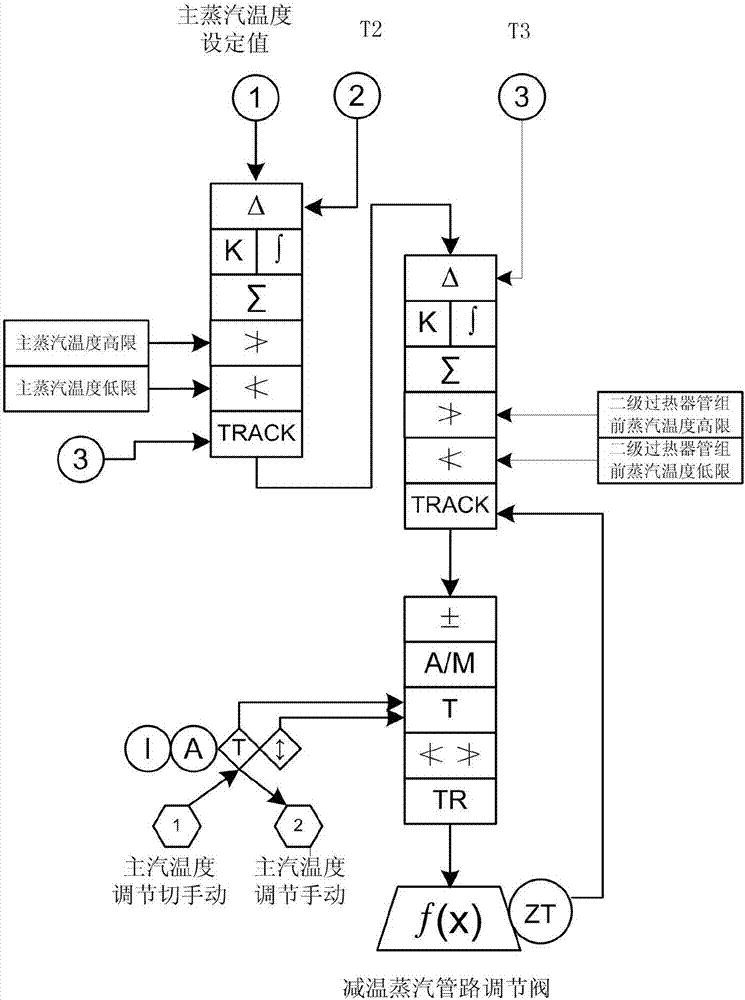

[0033] The new boiler main steam temperature adjustment method of this embodiment adopts the adjustment device described in Embodiment 1, and the temperature of the main steam detected by the main steam temperature measuring device and the inlet pipe of the secondary superheater are adjusted by the adjustment valve of the desuperheating steam pipeline. The steam temperature before the inlet tube group of the secondary superheater detected by the steam temperature measuring device before the group is adjusted and controlled, wherein the control method of the steam temperature before the inlet tube group of the secondary superheater is: adopting a decentralized control system for cascade PID Automatic adjustment, in which the main steam temperature is the main regulating variable, and the steam temperature before the inlet tube group of the secondary superheater is the secondary regulating variable; the isolating valve of the desuperheating steam pipeline is used to quickly cut of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com