Preparation process and equipment of citric acid cellulose phthalate

A technology of cellulose and citric acid, applied in the direction of mixers, feeding devices, chemical/physical/physicochemical processes, etc., can solve the problem that components cannot continue to work for a long time, thermal fatigue of equipment components, and affect the progress of processing and other problems to achieve the effect of preventing heat from being dissipated in time, increasing the contact area, and promoting air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

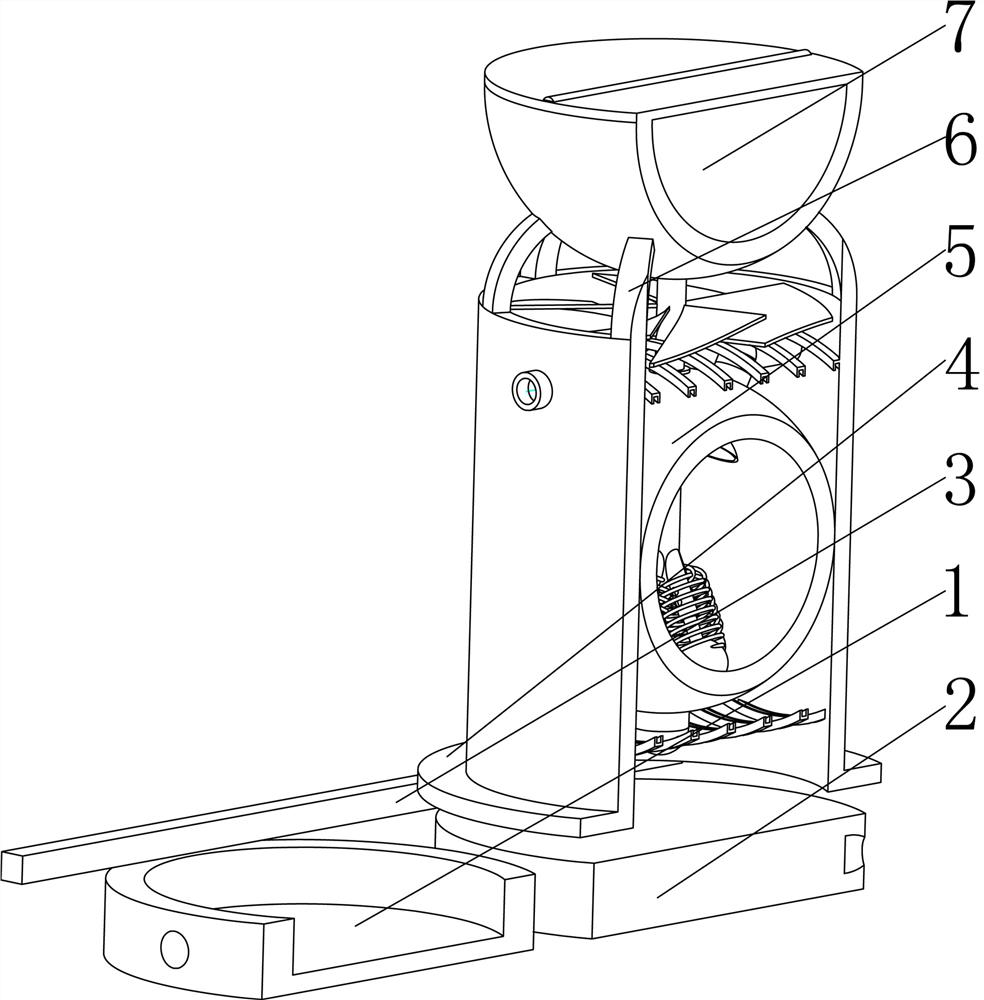

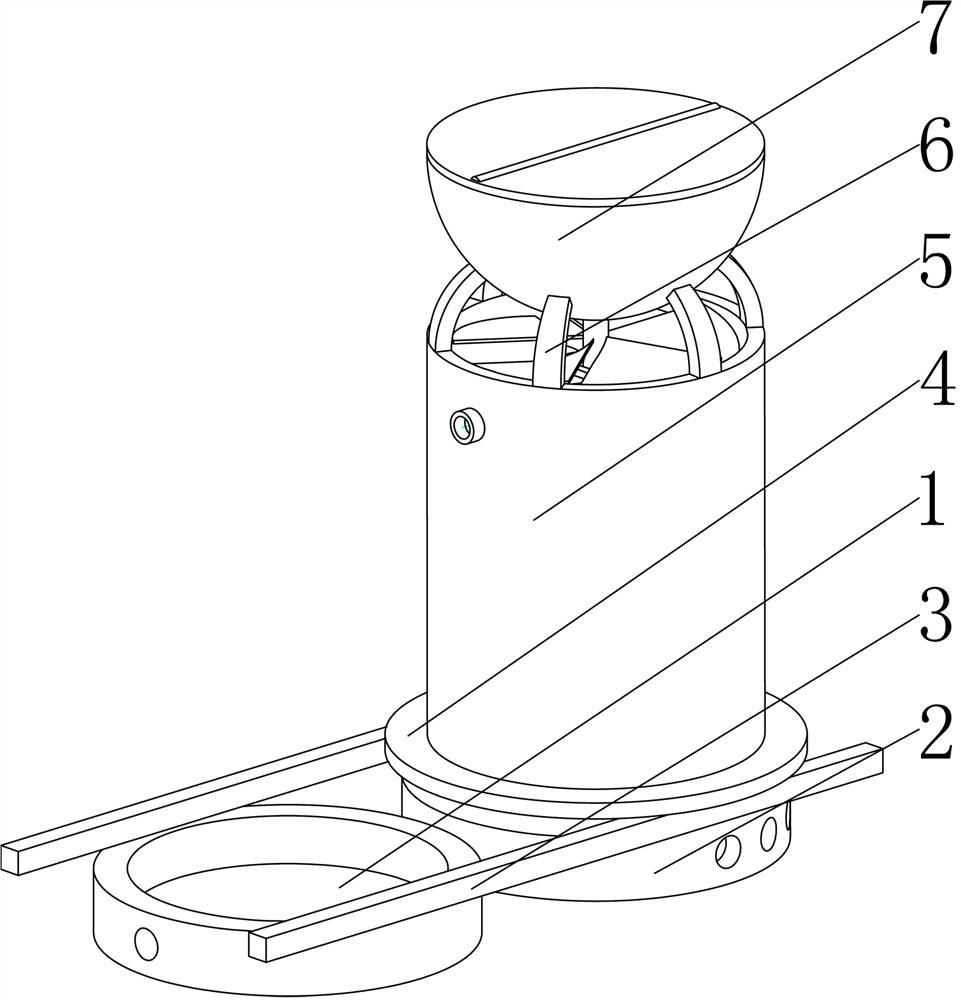

[0047] see Figure 1-7 , the present invention provides a technical solution: a preparation equipment for cellulose citrate phthalate, specifically comprising:

[0048] Material guide plate 1, the material guide plate 1 has a circular box, and the fan 2 installed on the right side of the outer surface of the material guide plate 1, and installed on the front and back rail slide bars 3 of the top of the circular box body, and installed on the The support slip ring 4 on the top of the track slide bar 3, and the esterification equipment 5 installed on the inner surface of the support slip ring 4, and the arc strut 6 installed on the top of the esterification equipment 5, and installed on the top of the arc strut 6 The hemispherical tank 7 provides the source of driving force for the overall equipment through the setting of the fan 2, reduces the contact area of the equipment components, and at the same time reduces the heat generated by the equipment itself when the equipment i...

Embodiment 2

[0060] see Figure 1-7 On the basis of Example 1, the present invention provides a technical solution: a preparation process of cellulose citrate phthalate, comprising the following steps,

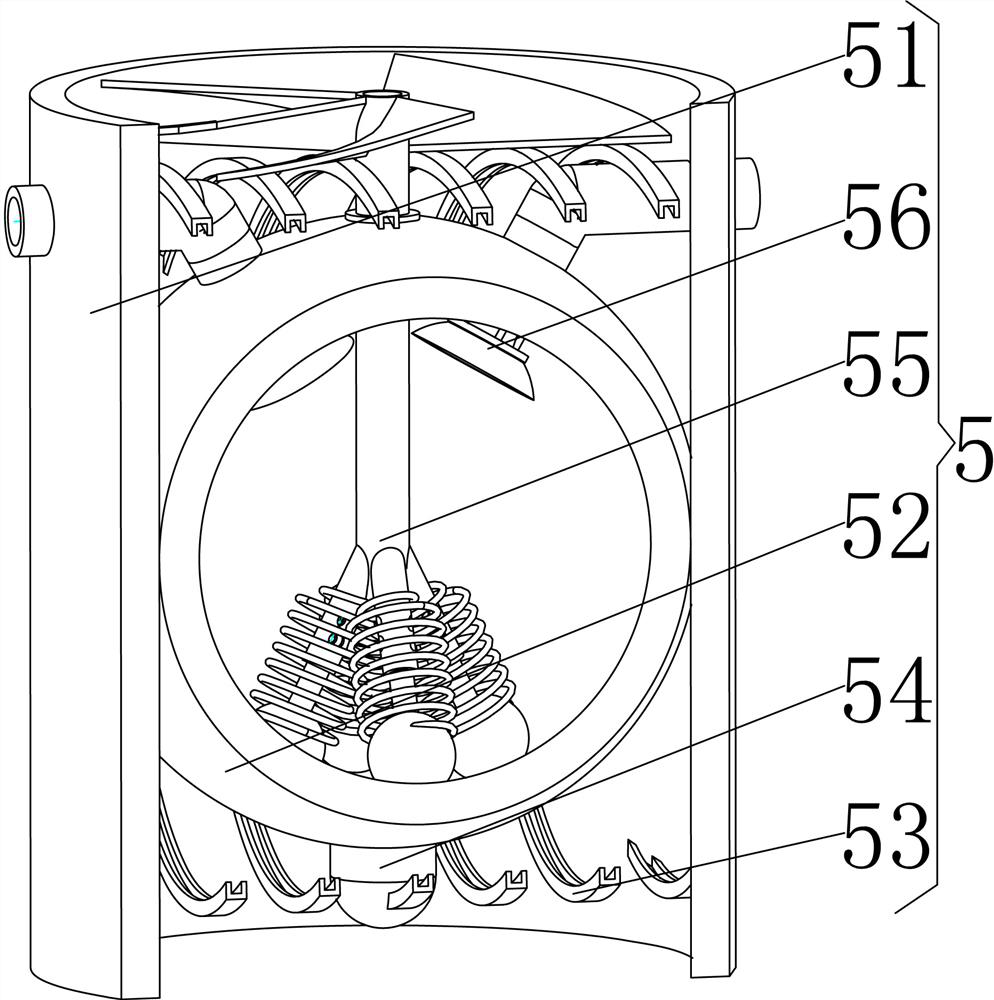

[0061] Step 1: Fill the hemispherical material tank 7 with citric acid, and fill the cellulose through the injection pipe 56 at the same time, so that the cellulose is infused into the inner cavity of the esterification spherical shell 52 through the sealing ring 562;

[0062] Step 2: Push the esterification device 5 along the track slide bar 3 through the support slip ring 4, so that the esterification device 5 is located directly above the fan 2;

[0063] Step 3: Start the fan 2 to infuse the air flow, the air flow rises along the protective tube 51, the air flow rises from the outer surface of the esterification spherical shell 52, blows the air flow fan blade 552, and the air flow fan blade 552 is driven to rotate by the air flow;

[0064] Step 4: The air flow fan blade 552 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com