Vertical heat exchanger with convex thin tube sheets

A heat exchanger and thin tube technology, applied in the field of vertical heat exchangers, can solve the stress corrosion and fatigue damage at the connection between the heat exchange tube and the tube sheet, the leakage failure at the connection between the heat exchange tube and the tube sheet, and reduce the use of equipment. Life and safety issues, to avoid thermal fatigue damage, reduce thermal fatigue damage, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

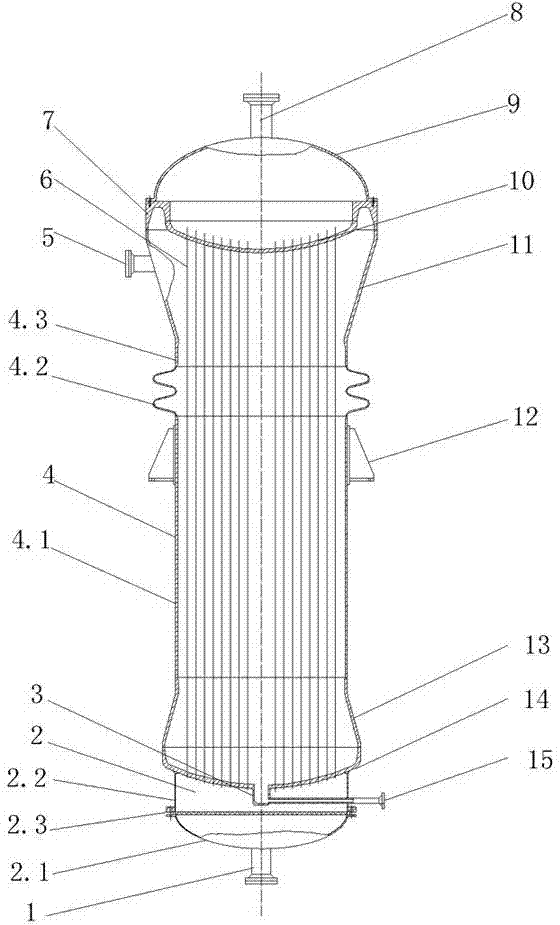

[0021] As shown in the drawings, the present invention includes a shell-side structure consisting of an upper tube box 9, an upper conical transition section 11, a shell-side cylinder 4, a lower conical transition section 13 and a lower tube box 2 and an upper tube plate 10 , tube bundle 6 and tube pass structure composed of lower tube plate 14; the upper tube box 9 is fixedly installed on the special-shaped flange 7, the lower end of the special-shaped flange 7 is an annular groove, and the upper tube plate 10 is connected to the annular groove at the lower end of the special-shaped flange 7 On the inner ring, the outer ring of the annular groove at the lower end of the special-shaped flange 7 is sealed and connected with the upper end of the shell-side cylinder 4 through the upper tapered transition section 11, and the lower end of the shell-side cylinder 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com