Nonlinear condensation water throttle control model

A condensate throttling and nonlinear model technology, applied in the direction of control of water supply, preheating, steam generation, etc., can solve the problems of complex model structure, unfavorable controller design, etc., and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

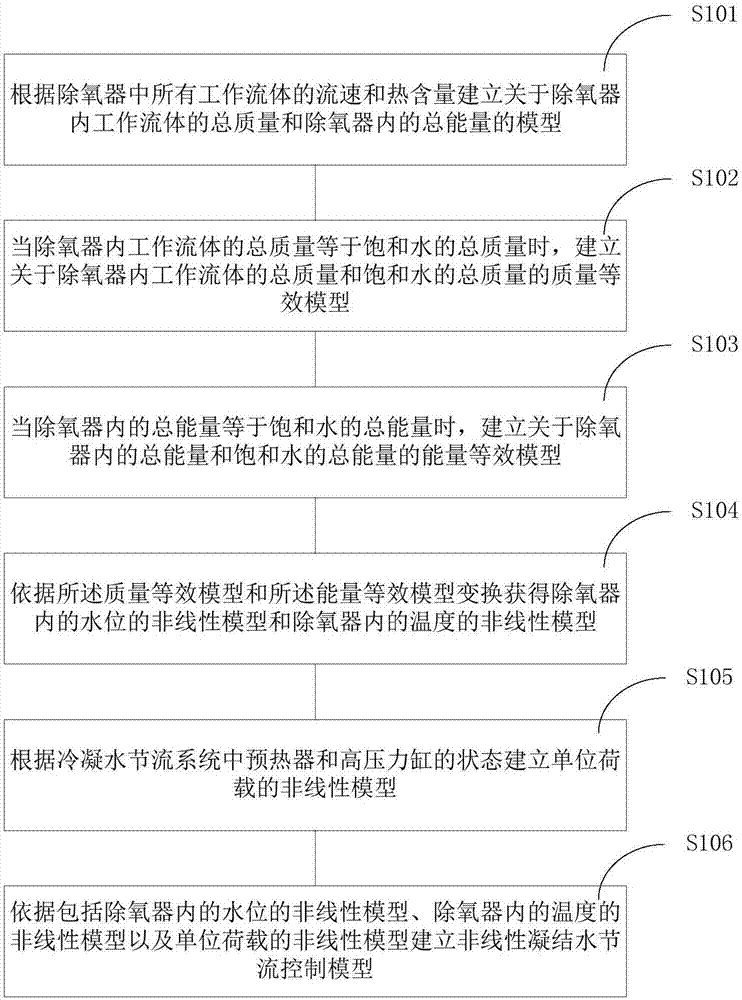

[0033] Such as figure 1 As shown, a nonlinear condensate throttling control model includes the following steps:

[0034] S101: Establish a model about the total mass of the working fluid in the deaerator and the total energy in the deaerator according to the flow rate and heat content of all working fluids in the deaerator, where the working fluid includes steam extraction from a medium-pressure cylinder, high-pressure preheating Heater drain water and condensate water and boiler feed water;

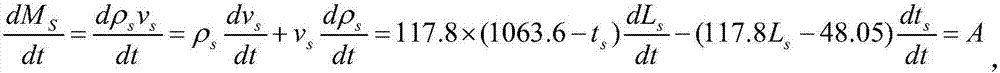

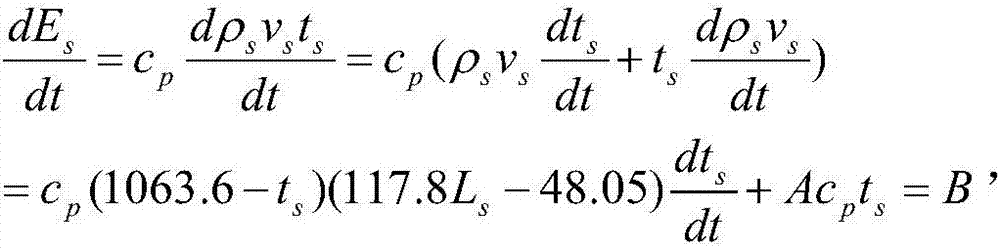

[0035] The specific content of step S101 is as follows: In this modeling process, the influence of saturated gas on the total mass and total energy of the deaerator can be ignored. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com