An industrial robot vision system and teaching method thereof

An industrial robot and vision system technology, applied in the field of automation control, can solve problems such as user programming and system complexity, and achieve the effects of small amount of calculation, reduced system complexity, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

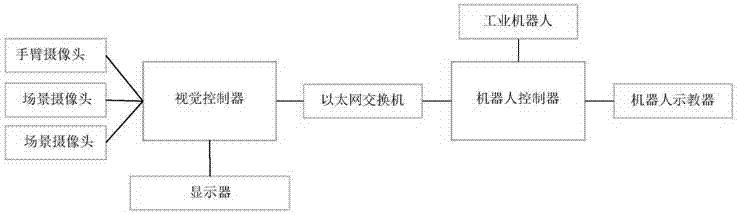

[0028] see figure 1 , an industrial robot vision system, including a camera, a vision controller, an Ethernet switch, a robot controller, and a robot teaching device; wherein, there are multiple cameras, which are set at any fixed position in the work scene or / placed on the robot arm The end moves with the robotic arm, the vision controller and the robot controller communicate through the Gigabit Ethernet network through the Ethernet switch, and the robot controller is connected to the robot teach pendant.

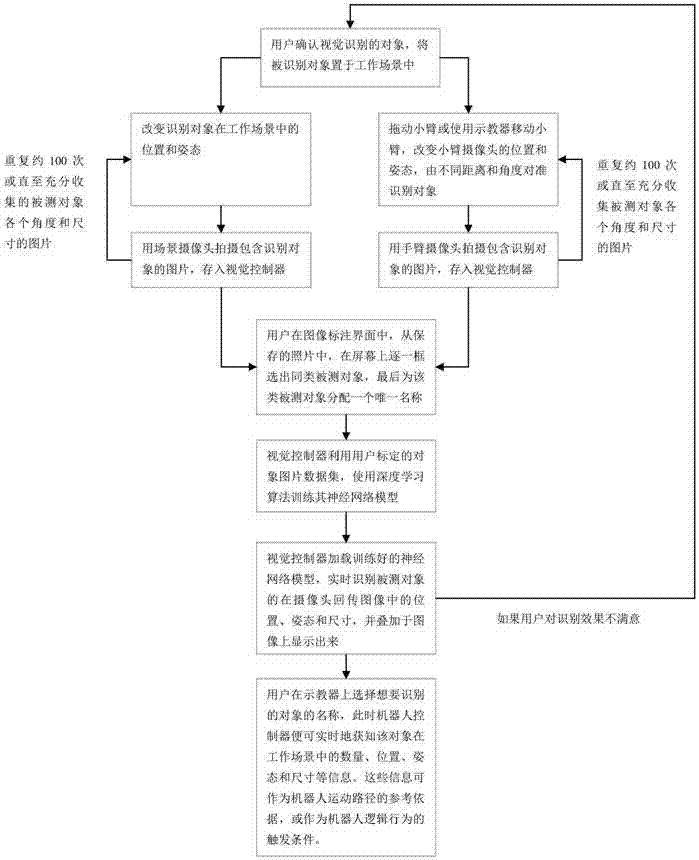

[0029] The working principle of the industrial robot vision system of the present invention is as follows: the picture of the object is recognized by the camera and stored in the vision controller, and the vision controller uses the object picture data set calibrated by the user to train its neural network model using a deep learn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com