A Lateral Insulated Gate Bipolar Transistor

A bipolar transistor, insulated gate technology, applied in semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of weakening the conductance modulation effect of the drift region, increasing the forward voltage drop, and unfavorable for the practical application of the device. Effects of high breakdown voltage, fast turn-off speed, and low turn-off loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

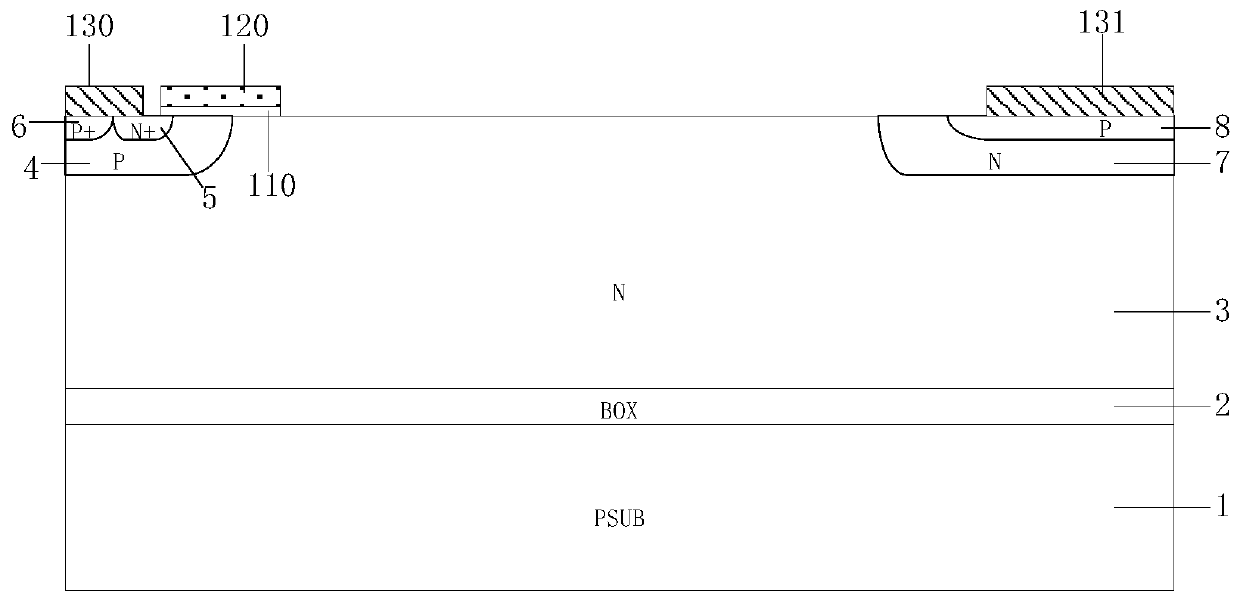

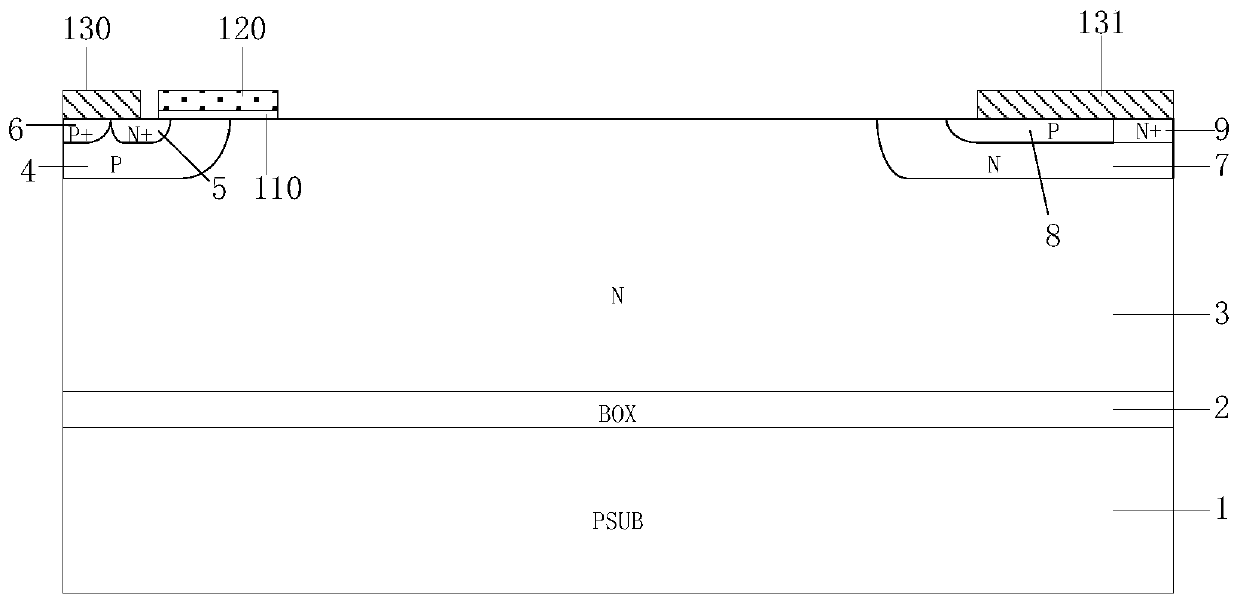

[0025] Such as image 3 As shown, it is a schematic structural diagram of this example, including a substrate 1, an insulating layer 2, and an N-type low-doped drift region 3 that are stacked sequentially from bottom to top; the upper sides of the N-type low-doped drift region 3 have respectively The P-type body region 4 and the N-type buffer zone 7, the upper layer of the P-type body region 4 has a P+ contact region 6 and an N+ emitter region 5 arranged side by side, wherein the N+ emitter region 5 is located on the side close to the N-type buffer region 7 , the N-type buffer area 7 has a P-type collector region 8 and a highly doped N+ region 9 arranged side by side, wherein the P-type collector region 8 is located on the side close to the P-type body region 4; the P+ contact The upper surface of the region 6 and part of the N+ emitter region 5 has an emitter metal electrode 130, and the upper surface of the P-type body region 4 has a first gate structure, and the first gate ...

Embodiment 2

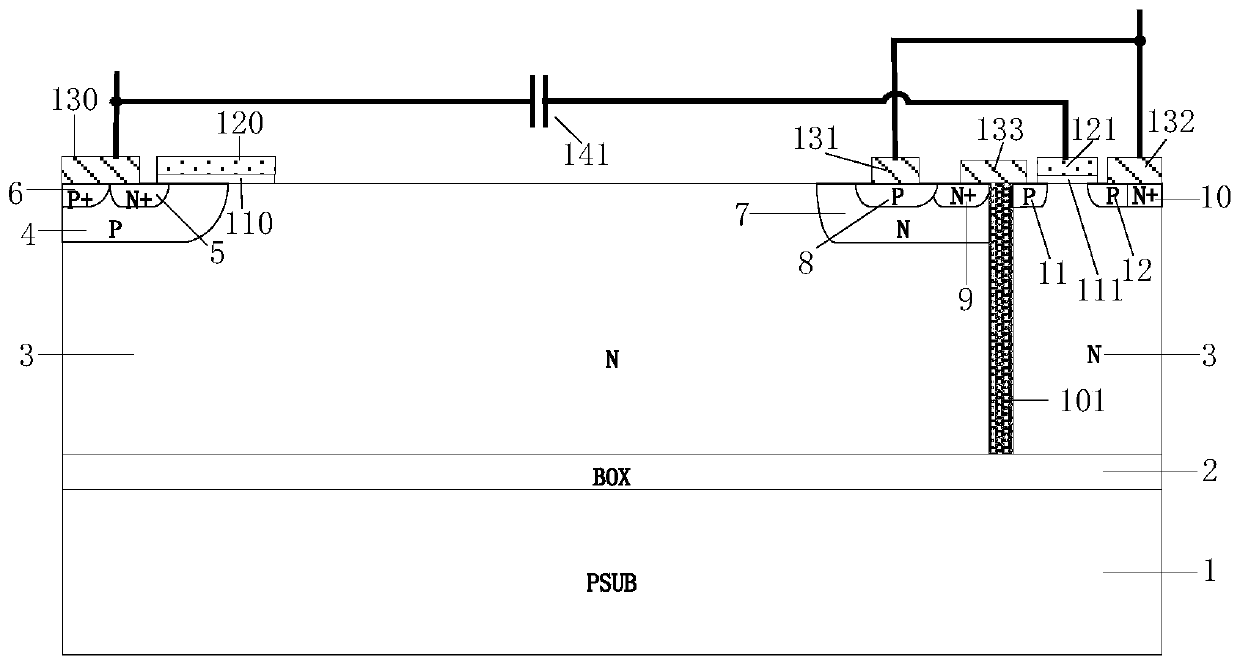

[0032] Such as Figure 4 As shown, the difference between this example and Example 1 is that in this example, compared with Example 1, the N+ region 10, the second P-type region 12, the dielectric layer 111, the polysilicon electrode 121, and the N-type low-doped drift region 3 and the PMOS formed by the first P-type region 11 is formed in the N-type well region 13 located on the surface of the N-type low-doped drift region 3 , the concentration of the N-type well region 13 is greater than the concentration of the N-type low-doped drift region 3 . Therefore, the breakdown voltage of the PMOS device in this example can be further increased, further improving the breakdown voltage of the device.

Embodiment 3

[0034] Such as Figure 5 As shown, compared with Embodiment 2, this example has a Zener diode 151 between the first metal electrode 132 and the second polysilicon electrode 121, wherein the cathode of the Zener diode 151 is connected to the first metal electrode 132 and the second polysilicon electrode 121. The collector metal electrode 131, the anode of the Zener diode 151 is connected to the second polysilicon electrode 121 and the capacitor 141; the stable voltage value of the Zener diode 151 is greater than the absolute value of the threshold voltage of the PMOS, and is less than that of the dielectric layer 111 of the PMOS device. Breakdown voltage value; the Zener diode 151 is integrated on the surface of the same device through a polysilicon layer. The Zener diode 151 further improves the charging and discharging speed of the capacitor 141, increases the turn-off speed of the LIGBT, reduces the turn-off loss, and improves the reliability of the integrated PMOS device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com