IGBT drive signal hardware interlocking and dead zone setting circuit

A technology for driving signals and hardware, applied in the electrical field, can solve the problems of reducing output efficiency, output waveform distortion, large dead time, etc., to avoid the risk of shoot-through and improve the level of safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

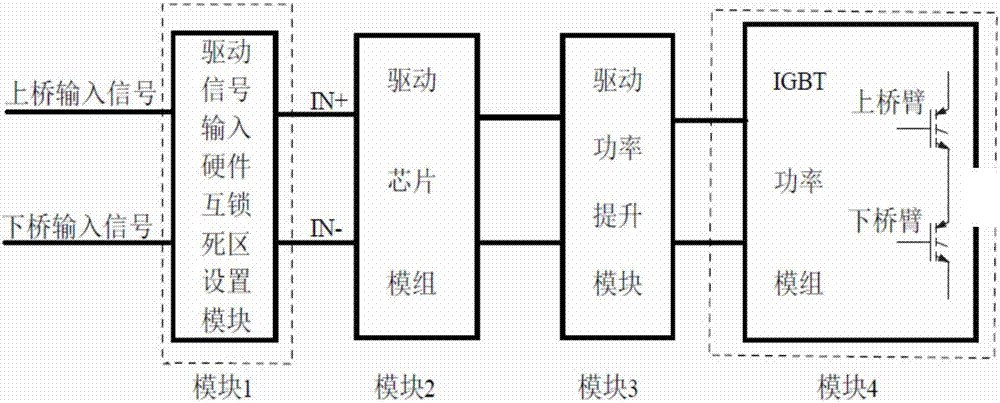

[0016] Such as figure 1 Shown is the block diagram of the IGBT drive system. Module 1 represents the input signal processing module and the IGBT drive signal interlock and hardware dead zone setting circuit. Module 2 represents the driver chip module. Module 3 represents the drive power boost module. Module 4 represents the IGBT module. .

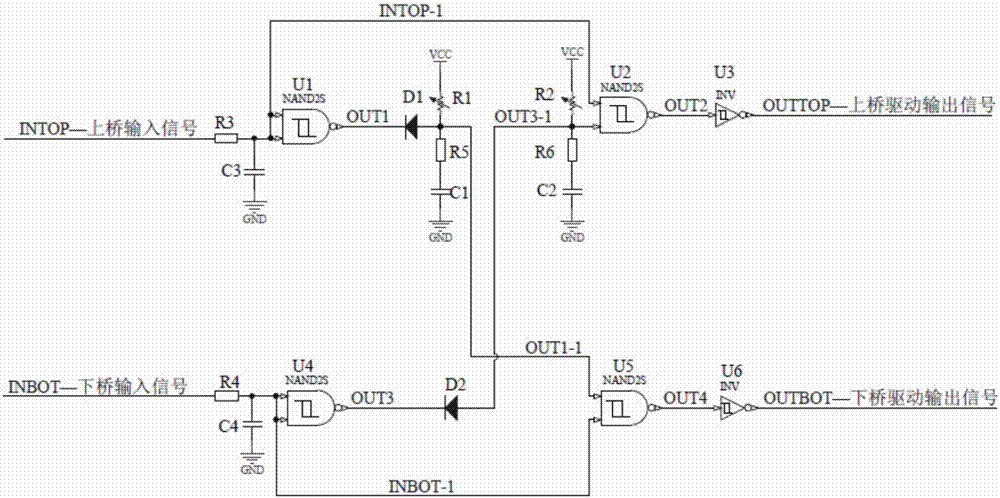

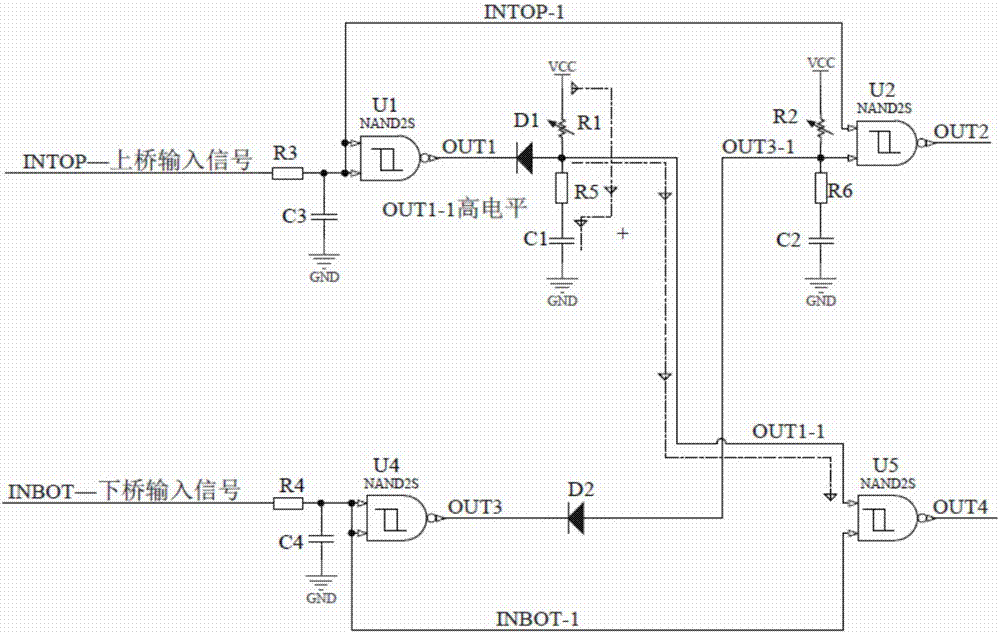

[0017] Such as figure 2 , image 3 and Figure 4 As shown, the IGBT drive signal hardware interlock and dead zone setting circuit of the present invention includes a first pull-up resistor R1, a second pull-up resistor R2, a third resistor R3, a fourth resistor R4, a first Fifth resistor R5, sixth resistor R6, first capacitor C1, second capacitor C2, third capacitor C3, fourth capacitor C4, first diode D1, second diode D2, first NAND gate Chip U1, the second NAND chip U2, the third NAND chip U3, the fourth NAND chip U4, the fifth NAND chip U5 and the sixth NAND chip U6, wherein the upper bridge input signal INTOP is connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com