High-expansion frozen drink and preparation method thereof

A frozen drink and puffing technology, which is applied in the direction of frozen sweets, food ingredients, sugar-containing food ingredients, etc., can solve problems that need to be improved, and achieve good shape retention, regular shape, and good melting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

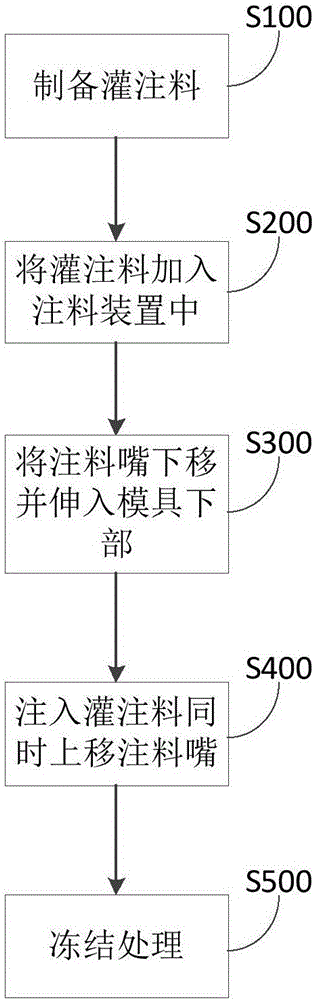

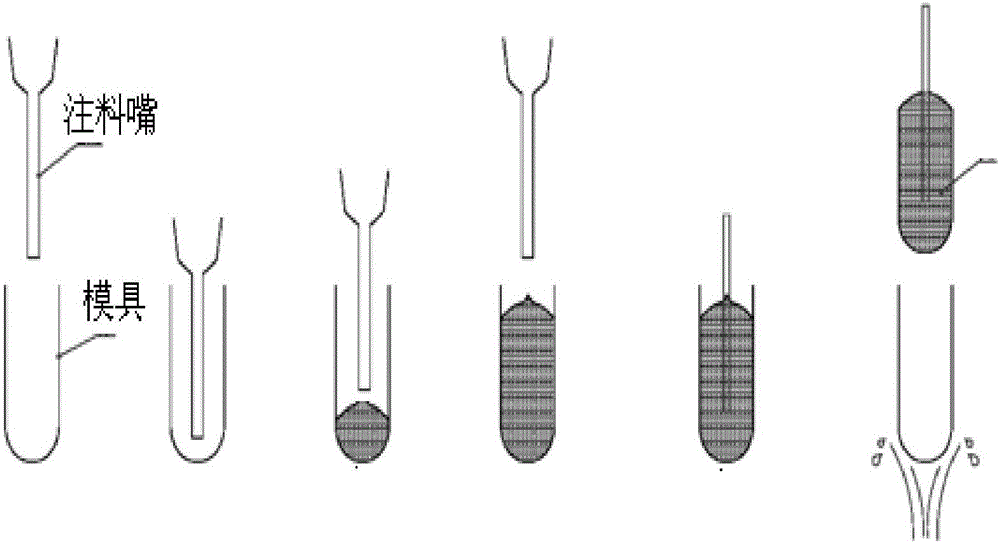

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, high puffed ice cream is prepared according to the following method:

[0066] 1. Formula (1000kg)

[0067] Maltose syrup: 100kg; white granulated sugar: 100kg; skimmed milk powder: 25kg; palm oil: 30kg; dextrin powder: 75kg; soybean powder (18% protein content): 25kg; 30% fatty acid ester, 10% sucrose fatty acid ester, 40% guar gum, 10% locust bean gum, 10% xanthan gum): 5.0kg; flavor for food: 1.0kg; the rest is drinking water.

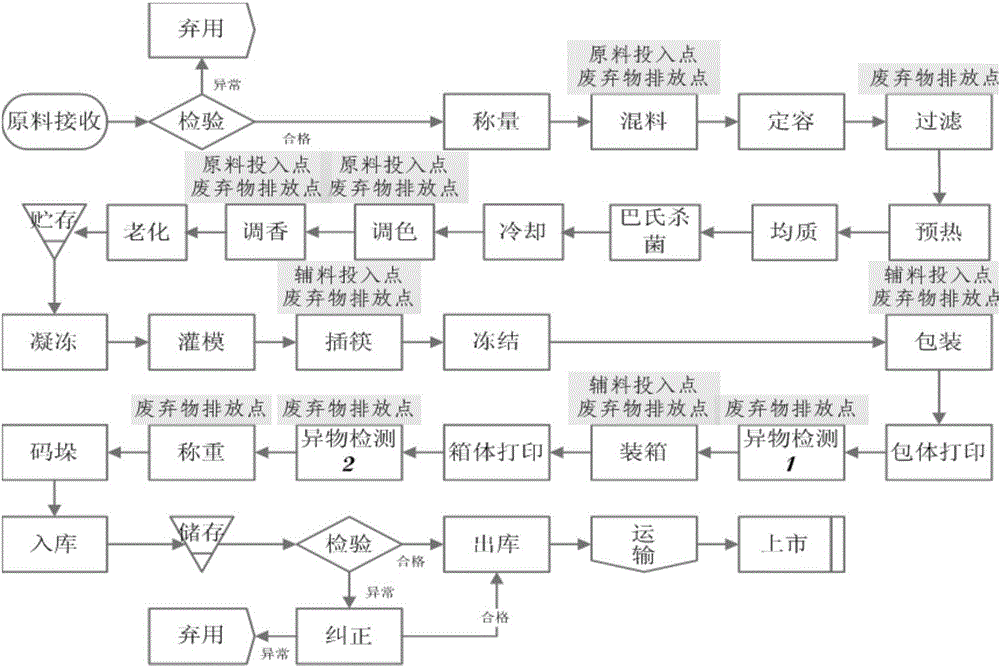

[0068] 2. Process flow such as image 3 shown.

[0069] Sterilization: the temperature is 87±2°C, and the holding time is 30-60s;

[0070] Homogenization: Homogenization temperature is 65-75°C, homogenization pressure is 130-150bar, primary pressure accounts for 80% (104-120bar), and secondary pressure accounts for 20% (24-30bar);

[0071] Aging: The aging temperature is 0-4°C, and the aging time is 2-48 hours.

[0072] Freezing: Make a 1000L continuous freezer, and the outlet temperature of the freezer is -1~-3°C.

...

Embodiment 2

[0076]Prepare high puffed ice cream according to the method for embodiment 1, difference is that formula is as follows:

[0077] Raw milk: 500kg; white sugar: 125kg; skimmed milk powder: 50kg; coconut oil: 80kg; glutinous rice flour: 5kg; Gum 15%, xanthan gum 10%, sodium carboxymethyl cellulose 30%): 5.0kg; food flavor: 1.0kg; the rest is drinking water.

[0078] According to the formula provided in this embodiment (conforming to the national standard for ice cream), through the above-mentioned production process, a kind of regular appearance, no holes, high expansion rate, fine and smooth taste, and good non-dairy cream ice cream can be obtained. The expansion rate is 100%, the solid content is 31%, and the protein content is 3%.

Embodiment 3

[0080] Prepare high puffed semi-cream ice cream according to the method of Example 1, the difference is that the formula is as follows:

[0081] Raw milk: 500kg; white granulated sugar: 125kg; skimmed milk powder: 50kg; coconut oil: 60kg; cream (milk fat content 33%): 50kg; glutinous rice flour: 5kg; Sorbitol 20%, Tween 80 5%, sodium alginate 30%, carrageenan 5%, gelatin 25%)): 5.0kg; food flavor: 1.0kg; the rest is drinking water.

[0082] According to the formula provided in this embodiment (conforming to the national ice cream standard), through the above-mentioned production process, a semi-cream ice cream with regular appearance, no holes, high expansion rate, delicate taste and good shape retention effect can be obtained. The expansion rate is 100%, the solid content is 31%, and the protein content is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com