One-dimensional closed-loop micro-nano vibration table

A vibrating table, micro-nano technology, used in fluids, instruments, measuring devices, etc. that use vibration, can solve problems such as inability to meet high-precision sensors, inability to generate vibration, time-consuming and labor-intensive adjustment, and achieve simple structure and high structural stability. , the effect of a large amplitude range

- Summary

- Abstract

- Description

- Claims

- Application Information

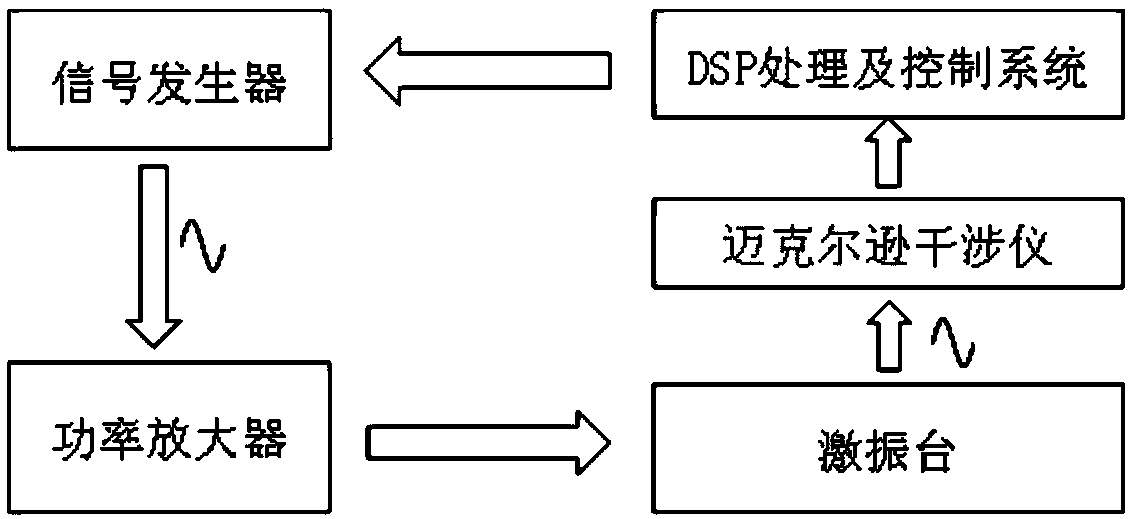

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

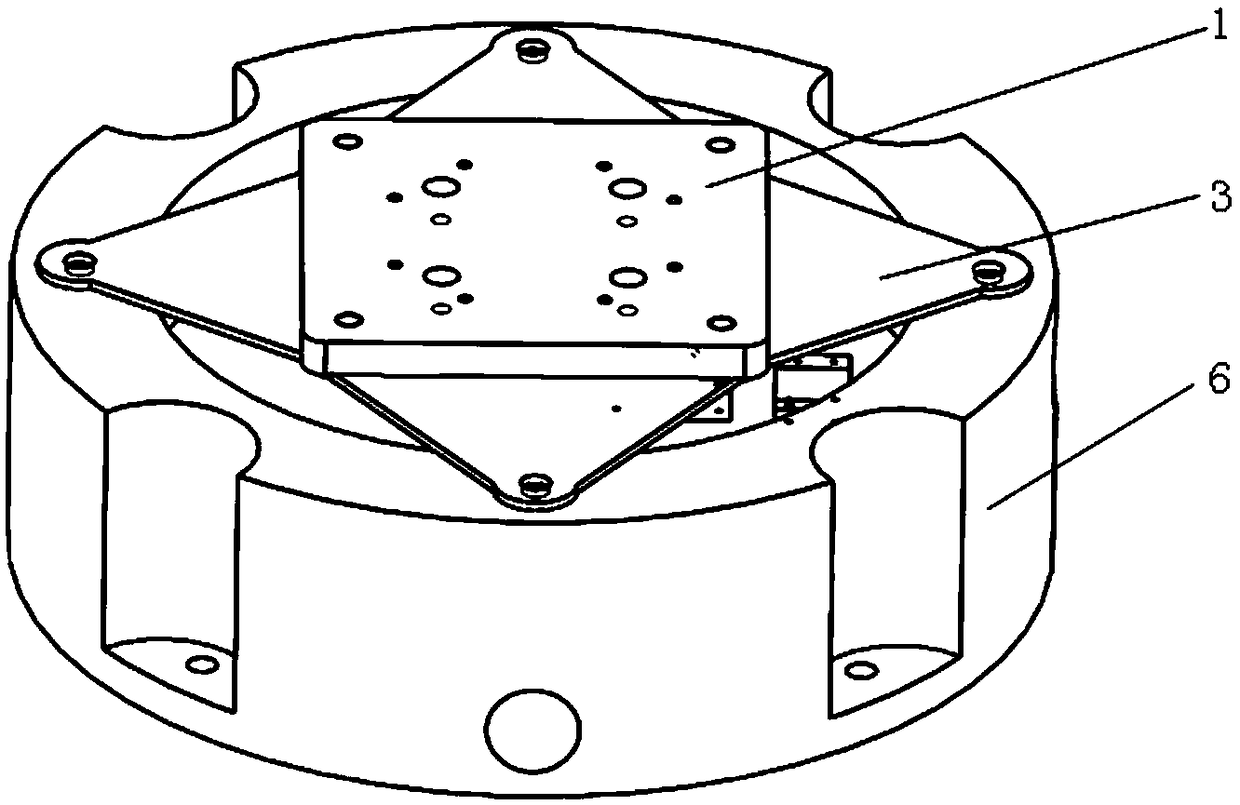

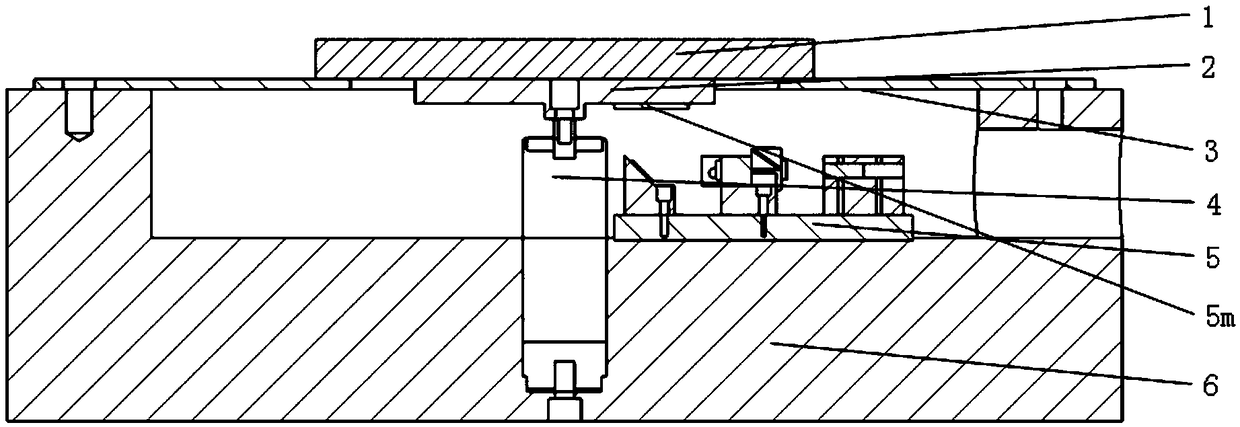

[0027] see figure 2 and image 3 , the structural form of the one-dimensional closed-loop micro-nano vibrating table in the present embodiment is: the beryllium copper reed 3 is used as the elastic component, the center of the beryllium copper reed 3 is a circular cavity, and the beryllium copper reed 3 utilizes a cross distribution The reed screws are fixed on the upper surface of the base 6; the worktable 1 is placed on the upper surface of the beryllium copper reed 3, and fixed on the beryllium copper reed 3 by table screws distributed in a cross to form an elastic structure, so that the worktable 1 The limit is obtained on the horizontal plane, and vibration displacement can be formed in the vertical direction; the shape and thickness of the beryllium copper reed 3 are optimized by ANSYS simulation to meet the application requirements.

[0028] Such as image 3 and Figure 4 As shown, the base 6 is a cylinder with a closed bottom and an open top, and a piezoelectric ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com