An automatic shifting vertical drilling machine

A drilling machine and automatic technology, which is applied to the components, driving devices, boring/drilling, etc. of the boring machine/drilling machine, can solve the problems of difficulty in shifting gears accurately, reduce the processing efficiency, affect the processing accuracy, etc., and achieve convenient and fast automatic switching. The effect of gear, reducing processing time and manpower, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

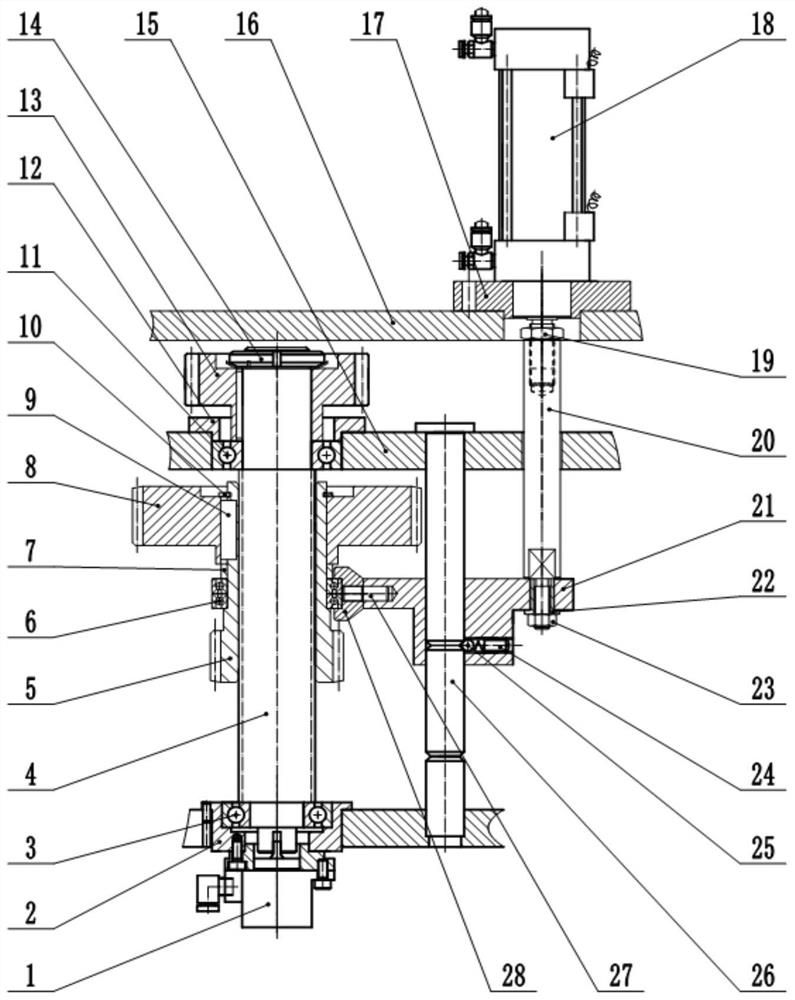

[0035] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

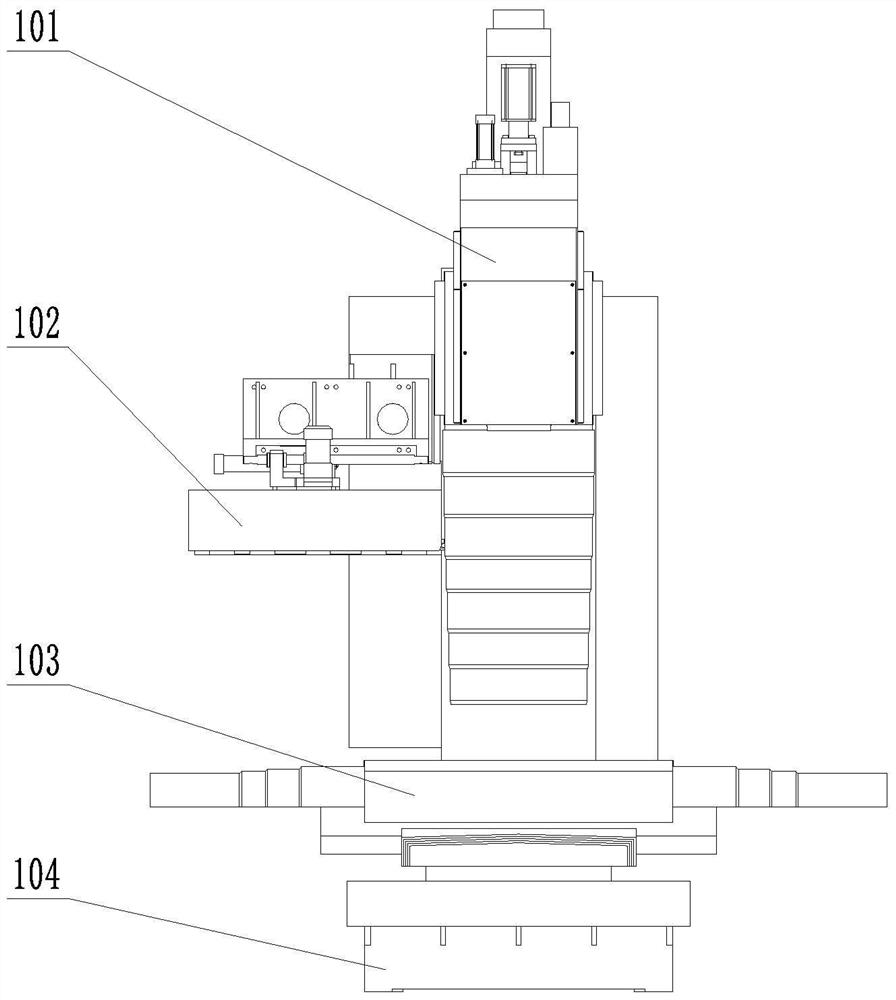

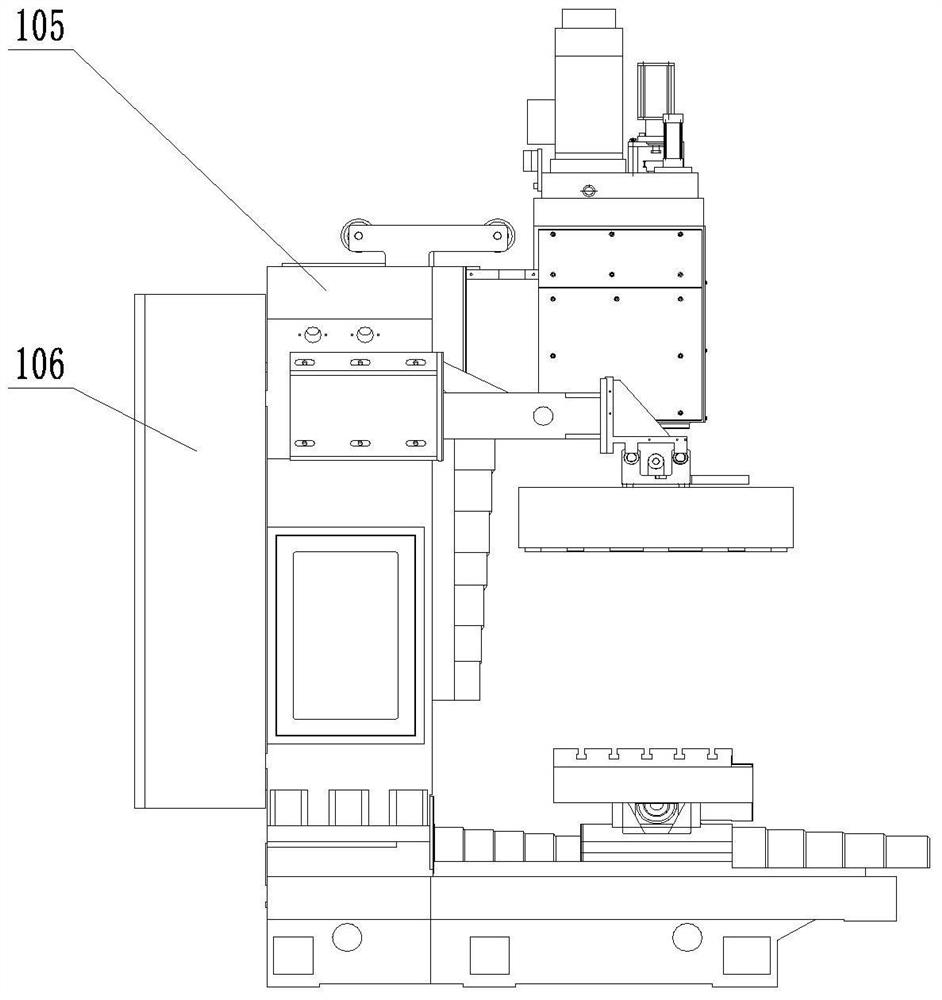

[0036] see figure 1 and 2 As shown, the automatic shifting vertical drilling machine of the embodiment of the present invention comprises a bed 104, a column 105 and a spindle box 101 at the upper end of the column 105, and a tool magazine 102 that can automatically change tools is set at the side of the bed 104; the spindle box 101 The lower side of the headstock 101 is provided with a workbench 103 opposite to it. An electric cabinet 106 is arranged at the rear of the bed 104 to control various actions of the drilling machine.

[0037] The spindle box 101 of the vertical drilling machine of the embodiment of the present invention slides on the cast iron quenching guide rail surface of the column 105, and the servo motor drives the spindle box 101 to move up and down; and the cylinder action to complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com