Lead-free solder alloy with low cost and high melting point and preparation method thereof

A lead-free solder alloy, high melting point technology, used in welding equipment, metal processing equipment, welding/cutting media/materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention also provides a method for preparing a lead-free solder alloy with low cost and high melting point, comprising the following steps:

[0070] Prepare and melt part of Sn with all other main components and auxiliary components except Sb components into master alloy;

[0071] Melting the remaining Sn and Sb in a vacuum induction heating furnace to generate an intermetallic compound Sb2Sn3, the melting temperature of which is 380-450° C., and fully stirring for 60-90 minutes; and

[0072] The intermetallic compound Sb2Sn3 which is dissolved and stirred evenly is added to the master alloy, cooled after being fully stirred, and a lead-free solder alloy with low cost and high melting point is prepared by casting.

[0073] In a specific implementation, the trace alloy is one or more of Co, Mn, Al and Si.

[0074] In specific implementation, the content and composition of the trace alloy are as follows:

[0075] 0.00~0.20%Co,

[0076] 0.00~0.20% Mn,

[...

Embodiment 1

[0094] The lead-free solder alloy with low cost and high melting point includes the following main components, auxiliary components and the balance Sn, calculated by weight percentage, the composition and content of the main components are as follows: Sb15%, Cu1.5%, Bi0.1% , Ni0.05%; the auxiliary components include microalloys for improving the microscopic crystal structure and trace antioxidants for anti-oxidation, the microalloys include Co0.05%, Mn0.1% and Si0.1%, The trace antioxidant includes P0.05% and Ge0.1%, and the balance is Sn.

[0095] The preparation method of the above-mentioned lead-free solder alloy with low cost and high melting point comprises the following steps:

[0096] Prepare part of Sn and all other main components and auxiliary components except Sb components and melt them into master alloy; the amount of Sn used in this step can be based on all other main components and auxiliary components except Sb components The content and the preparation ratio ...

PUM

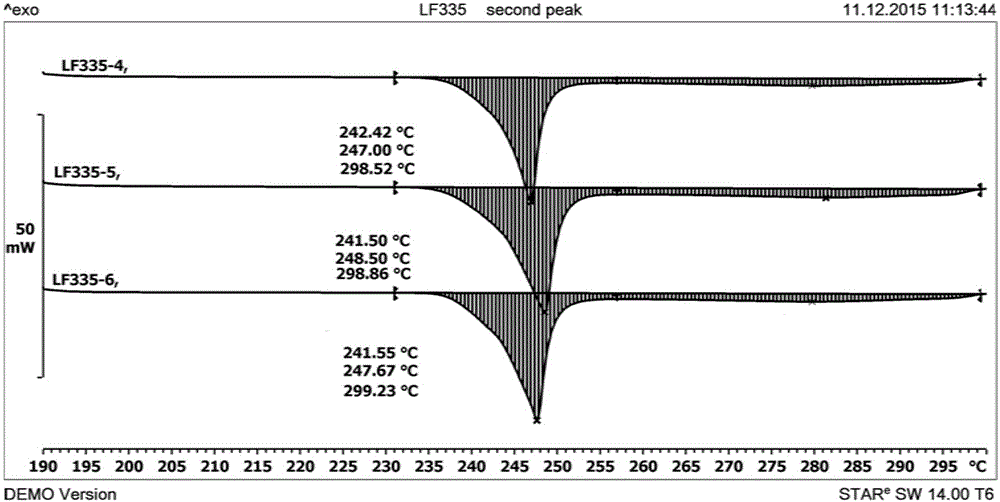

| Property | Measurement | Unit |

|---|---|---|

| Liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com