Near-bit composite torsion-reducing rock-breaking device

A rock-breaking device and near-bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of complex wellbore structure design, low efficiency, low cementing quality, etc., so as to facilitate mass production and large-scale promotion Application, control principle is simple, improve the effect of development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the drawings.

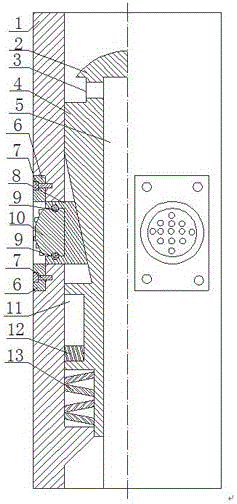

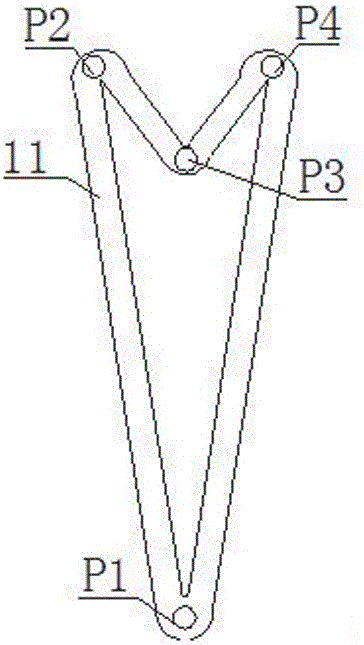

[0017] Reference attached figure 1 , The near-bit composite torsion-reducing rock breaking device is mainly composed of housing, 1, mushroom head 2, bypass hole 3, central shaft 4, central hole 5, gland 6, bolt 7, base 8, bearing 9, blade 10, The sliding groove 11, the positioning pin 12, and the spring 13 are composed. The mushroom head 2 is installed on the upper part of the central shaft 4, the central shaft 4 is processed with a central hole 5, the mushroom head 2 is processed with a bypass hole 3, the bypass hole 3 is connected to the central hole 5, the base 8 is connected with the central shaft 4, and the blade 10 is installed in the base 8, and a bearing 9 is installed between it and the base 8. The gland 6 is installed on the outer shell 1 and fixed by bolts 7. The outer wall of the lower part of the central shaft 4 is processed with a sliding groove 11, positioning pins 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com