Composite graphene far-infrared floor heating brick and floor heating device

A graphene composite and composite graphene technology, applied in the field of decorative materials, can solve the problems of slow heating, high energy consumption, and large electromagnetic radiation of floor heating for gas water pipe floor heating, so as to achieve a small occupied indoor height, solve radiation hazards, and quickly generate heat. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

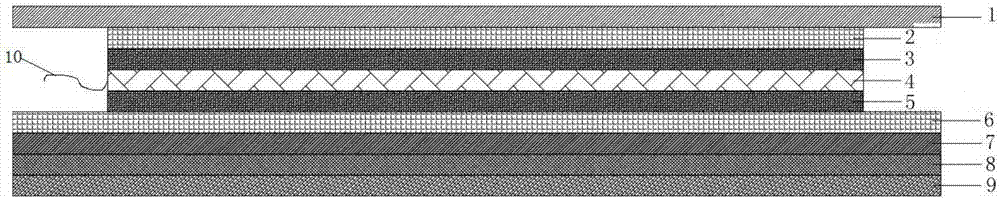

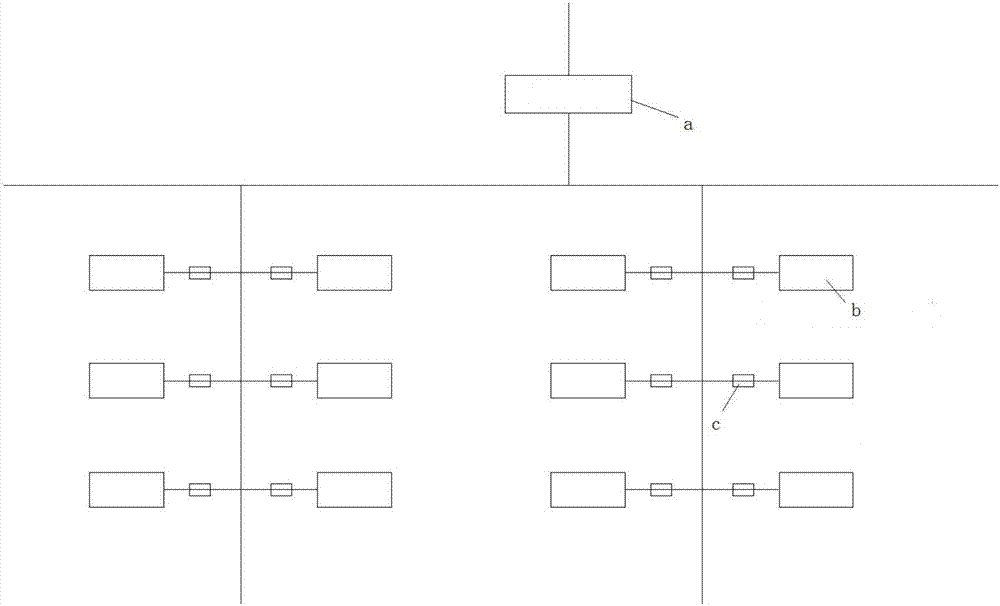

[0028] Such as figure 1 As shown, a graphene composite far-infrared floor heating tile a includes a nine-layer structure, from top to bottom: tile layer 1, first resin adhesive layer 2, first PC flame-retardant insulating layer 3, high-performance composite Graphite heating film layer 4, second PC flame retardant insulating layer 5, second resin adhesive layer 6, aluminum foil layer 7, glass fiber layer 8 and silicon rubber coating 9. The thickness of each layer is specifically as follows: the thicknesses of the first resin adhesive layer 2 and the second resin adhesive layer are both 0.05-0.1 mm; the thicknesses of the first PC flame-retardant insulating layer 3 and the second PC flame-retardant insulating layer 5 are both 0.1-0.2mm; the thickness of the high-performance composite graphite heating film layer 4 is 1.95-2.05mm; the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com