An external automatic monitoring and protection system for mining machinery

A technology of automatic monitoring and protection system, applied in the direction of measuring heat, measuring devices, using electrical devices, etc., it can solve the problems of losing automatic monitoring operation status and protection, not having much practical significance, and difficult to find alternative equipment, etc., to achieve convenient personality Optimized settings, reduced maintenance time and economic costs, and high temperature acquisition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

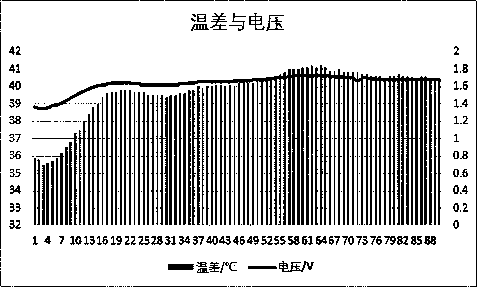

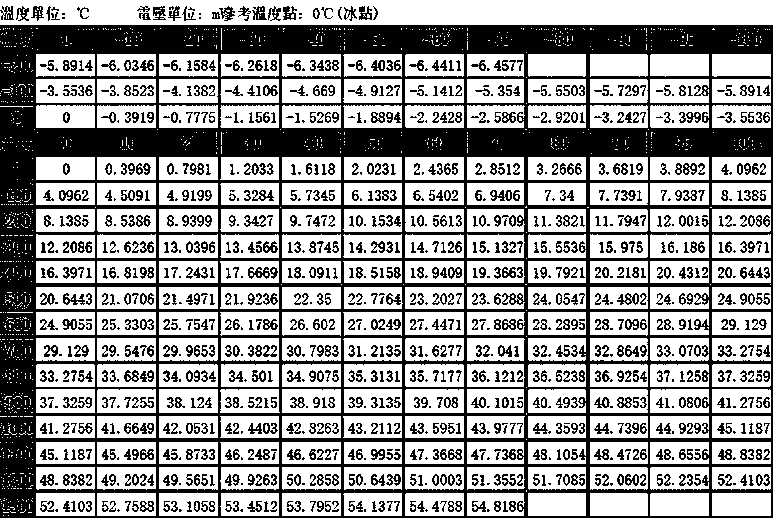

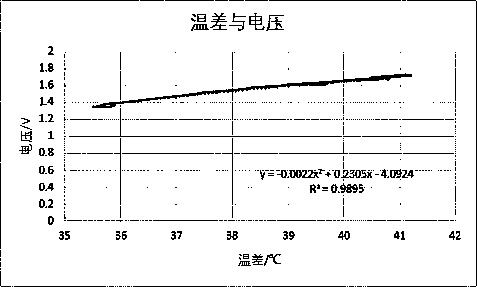

[0020] An external mining machinery automatic monitoring and protection system of the present invention includes: a temperature acquisition module, a voltage acquisition module for collecting temperature signals collected by the temperature acquisition module, and an intelligent analysis and control module; wherein the temperature acquisition module consists of a Rectangular thermoelectric material is composed independently. The temperature acquisition module is installed on the surface of the device shell of the measured temperature. One side of it contacts the surface of the device, and the other side is heat-dissipated to maintain the temperature difference. The voltage acquisition module transmits the data measured by the temperature acquisition module. For the intelligent analysis module and the control module, the intelligent analysis and control module compensates and corrects the data accordingly, and calculates the corresponding surface temperature of the device through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com