Xinjiang saline-alkali oil improvement method using desulphurization gypsum

A technology for desulfurizing gypsum and saline-alkali land, applied in the fields of land preparation methods, applications, agricultural machinery and implements, etc., can solve the problems of high water resource dependence, long planting process, low agricultural yield, etc. The effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

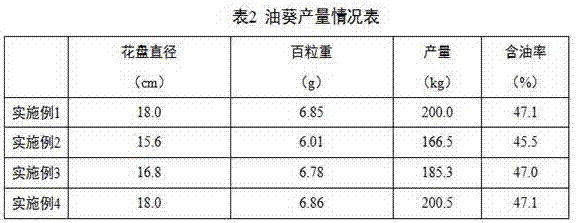

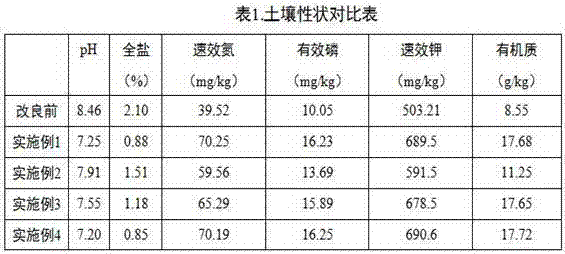

Embodiment 1

[0031] A method for improving saline-alkali land in Xinjiang with desulfurized gypsum, comprising the following steps:

[0032] S1. Grinding the humic acid-containing raw material to 100 mesh, the humic acid-containing raw material is lignite, adding water, the weight ratio of the humic acid-containing raw material to water is 1:5, performing wet ball milling, precipitation, separation, supernatant The liquid is an aqueous solution containing fulvic acid, and the precipitate is a mixture of brown humic acid and black humic acid;

[0033] S2. In August, plow the soil to 27cm deep, spray diammonium hydrogen phosphate on the unturned soil surface, the amount of diammonium hydrogen phosphate is 2kg / mu, spread desulfurization gypsum, and CaSO in desulfurization gypsum 4 2H 2 The weight content of O is >82%, and the dosage of desulfurized gypsum is 1900kg / mu;

[0034] S3. Mix the turned up soil with the mixture of brown humic acid and black humic acid, cinder and coconut bran obta...

Embodiment 2

[0038] A method for improving saline-alkali land in Xinjiang with desulfurized gypsum, comprising the following steps:

[0039] S1. Grinding the humic acid-containing raw material to 50 mesh, the humic acid-containing raw material is lignite, adding water, the weight ratio of the humic acid-containing raw material to water is 1:2, performing wet ball milling, sedimentation, separation, supernatant The liquid is an aqueous solution containing fulvic acid, and the precipitate is a mixture of brown humic acid and black humic acid;

[0040] S2. In August, plow the soil to 25cm deep, spray diammonium hydrogen phosphate on the unturned soil surface, the dosage of diammonium hydrogen phosphate is 0.5kg / mu, spread desulfurization gypsum, and CaSO in desulfurization gypsum 4 2H 2 The weight content of O is >82%, and the dosage of desulfurized gypsum is 1500kg / mu;

[0041] S3. mix the turned up soil with the mixture of brown humic acid and black humic acid obtained in step S1, coal ci...

Embodiment 3

[0045] A method for improving saline-alkali land in Xinjiang with desulfurized gypsum, comprising the following steps:

[0046]S1. Grinding the raw material containing humic acid to 200 mesh, the raw material containing humic acid is lignite, adding water, the weight ratio of raw material containing humic acid and water is 1:10, carrying out wet ball milling, precipitation, separation, supernatant The liquid is an aqueous solution containing fulvic acid, and the precipitate is a mixture of brown humic acid and black humic acid;

[0047] S2. In August, plow the soil to 25cm deep, spray diammonium hydrogen phosphate on the unturned soil surface, the dosage of diammonium hydrogen phosphate is 3kg / mu, spread desulfurization gypsum, and CaSO in desulfurization gypsum 4 2H 2 The weight content of O is >82%, and the dosage of desulfurization gypsum is 2000kg / mu;

[0048] S3. mix the turned up soil with the mixture of brown humic acid and black humic acid obtained in step S1, coal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com