A sand-carrying drag-reducing two-way fracturing fluid

A technology of fracturing fluid and jelly fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of cross-linking and temperature resistance, and achieve low reservoir damage, complete gel breaking, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

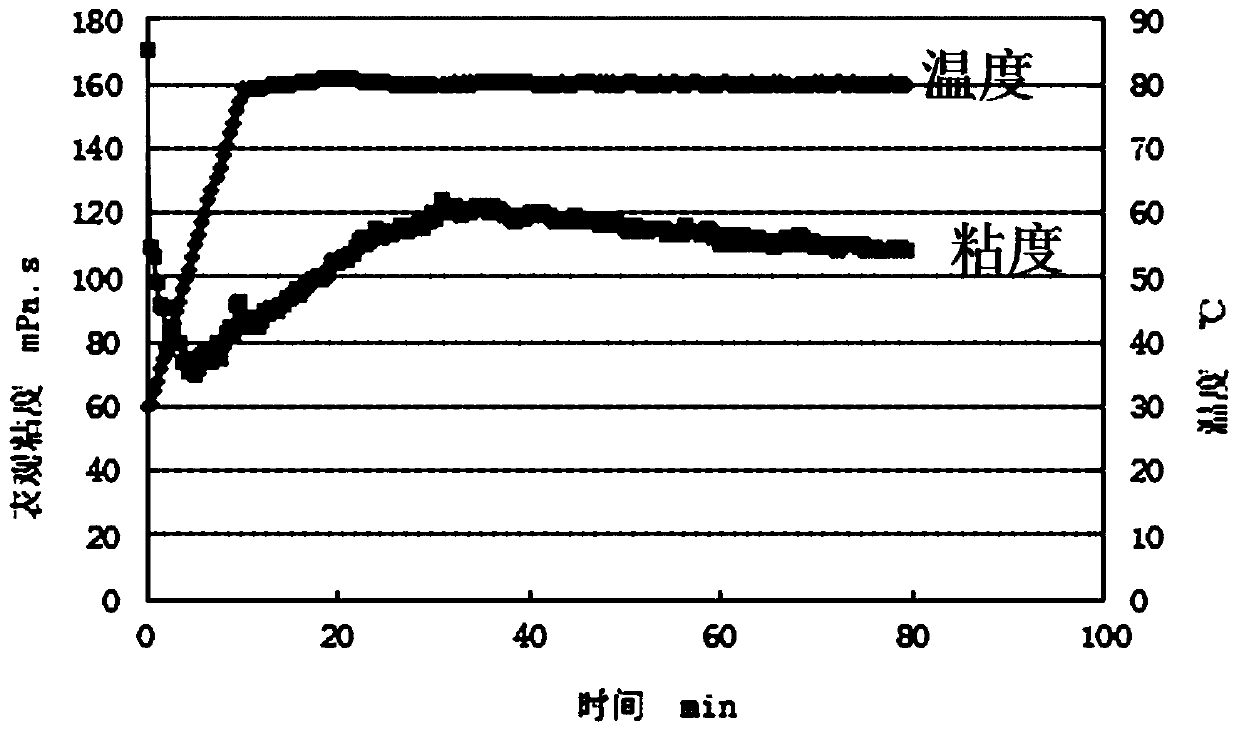

Embodiment 1

[0044] This embodiment provides a sand-carrying drag-reducing two-way fracturing fluid (slick water fracturing fluid), which is prepared through the following steps:

[0045] In terms of parts by mass, 98.82 parts of water, 0.5 parts of potassium chloride, 0.08 parts of thickener, 0.3 parts of drainage aid, and 0.3 parts of anti-swelling agent; under stirring conditions, add potassium chloride, thickener, drainage aid agent, anti-swelling agent, and stirred for 2 minutes to mix evenly to obtain slippery water fracturing fluid.

[0046] The drag reduction rate of the above-mentioned slick water fracturing fluid in this embodiment is 70.87%.

[0047] This embodiment provides a sand-carrying drag-reducing two-way fracturing fluid (jelly fracturing fluid), which is prepared through the following steps:

[0048] In terms of parts by mass, 97.3 parts of water, 0.5 parts of potassium chloride, 1.0 parts of thickener, 0.3 parts of drainage aid, 0.3 parts of cross-linking retarder and...

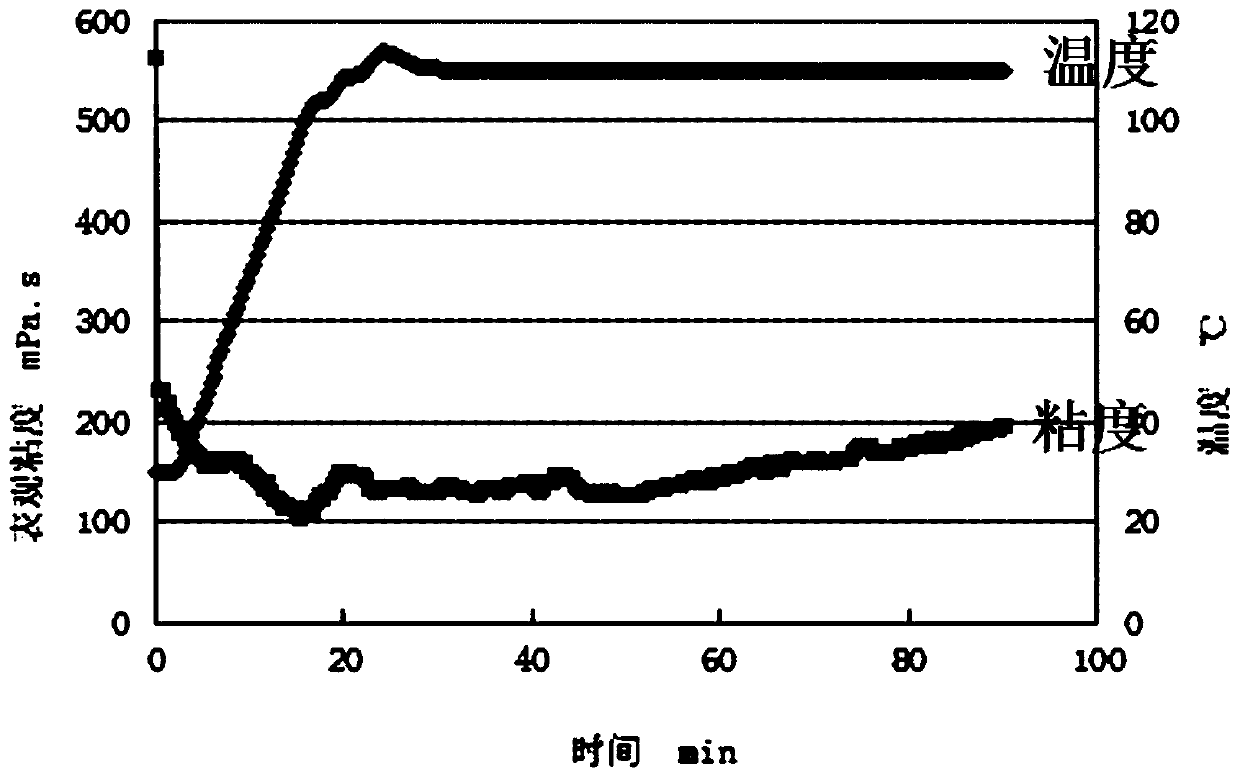

Embodiment 2

[0054] This embodiment provides a sand-carrying drag-reducing two-way fracturing fluid (slick water fracturing fluid), which is prepared through the following steps:

[0055] In terms of parts by mass, 98.31 parts of water, 1 part of potassium chloride, 0.09 parts of thickener, 0.3 parts of drainage aid, and 0.3 parts of anti-swelling agent; under stirring conditions, add potassium chloride, thickener, drainage aid agent, anti-swelling agent, and stirred for 2 minutes to mix evenly to obtain slippery water fracturing fluid.

[0056] The drag reduction rate of the slick water fracturing fluid in this embodiment is 71.01%.

[0057] This embodiment provides a sand-carrying drag-reducing two-way fracturing fluid (jelly fracturing fluid), which is prepared through the following steps:

[0058] In terms of parts by mass, 96.5 parts of water, 1 part of potassium chloride, 1.2 parts of thickener, 0.3 parts of drainage aid, 0.4 parts of cross-linking retarder, and 0.6 parts of cross-l...

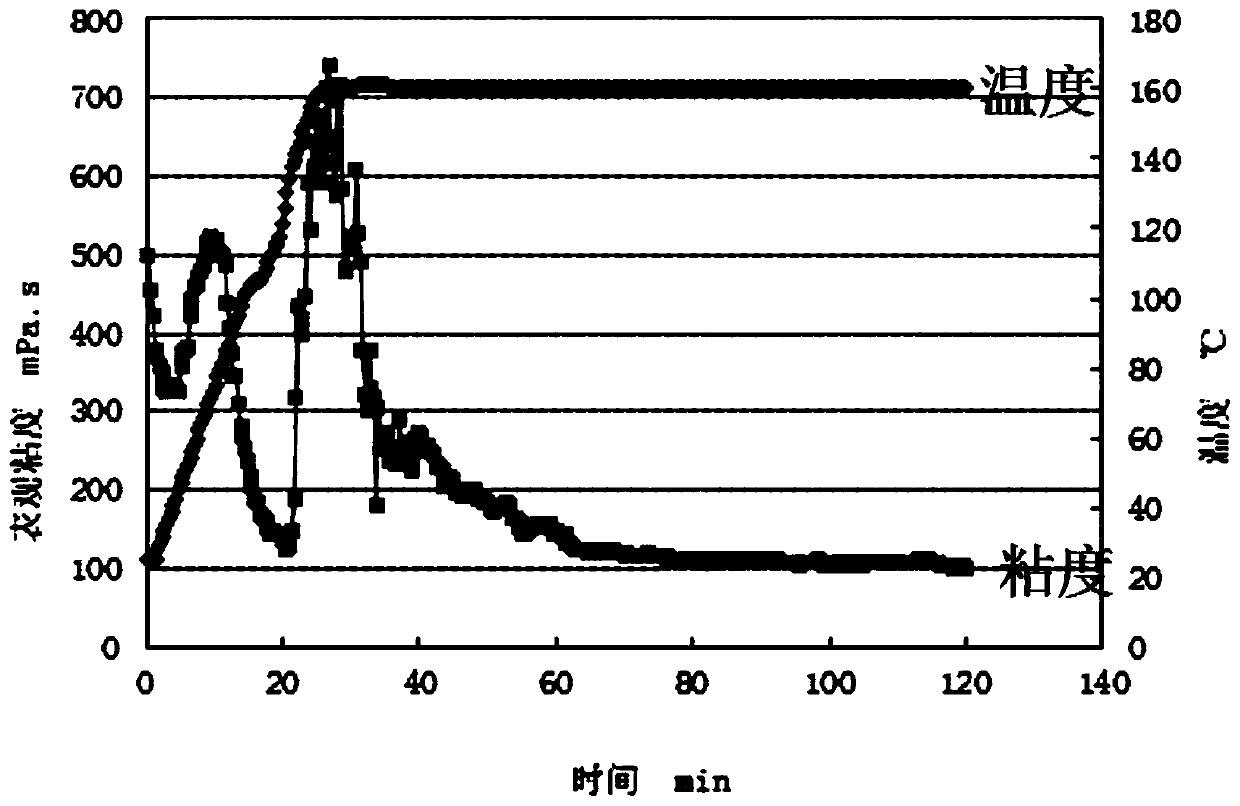

Embodiment 3

[0064] This embodiment provides a sand-carrying drag-reducing two-way fracturing fluid (slick water fracturing fluid), which is prepared through the following steps:

[0065] In terms of parts by mass, 96.92 parts of water, 2 parts of potassium chloride, 0.08 parts of thickener, 0.5 parts of drainage aid, and 0.5 parts of anti-swelling agent; under stirring conditions, add potassium chloride, thickener, drainage aid agent, anti-swelling agent, and stirred for 2 minutes to mix evenly to obtain slippery water fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com