Hypereutectic aluminium-silicon alloy alterant and application

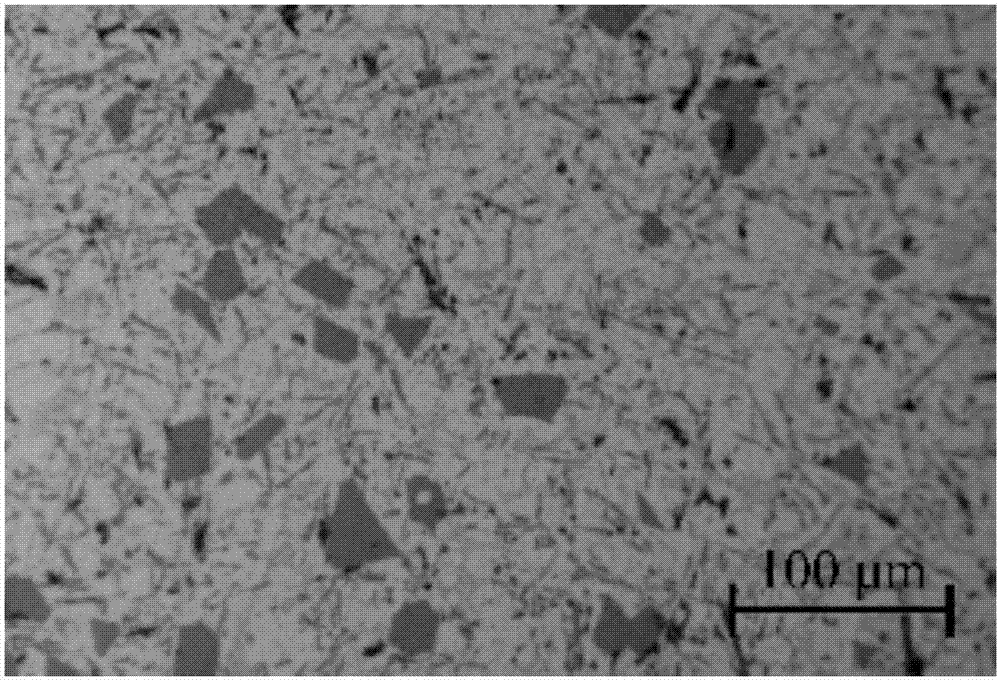

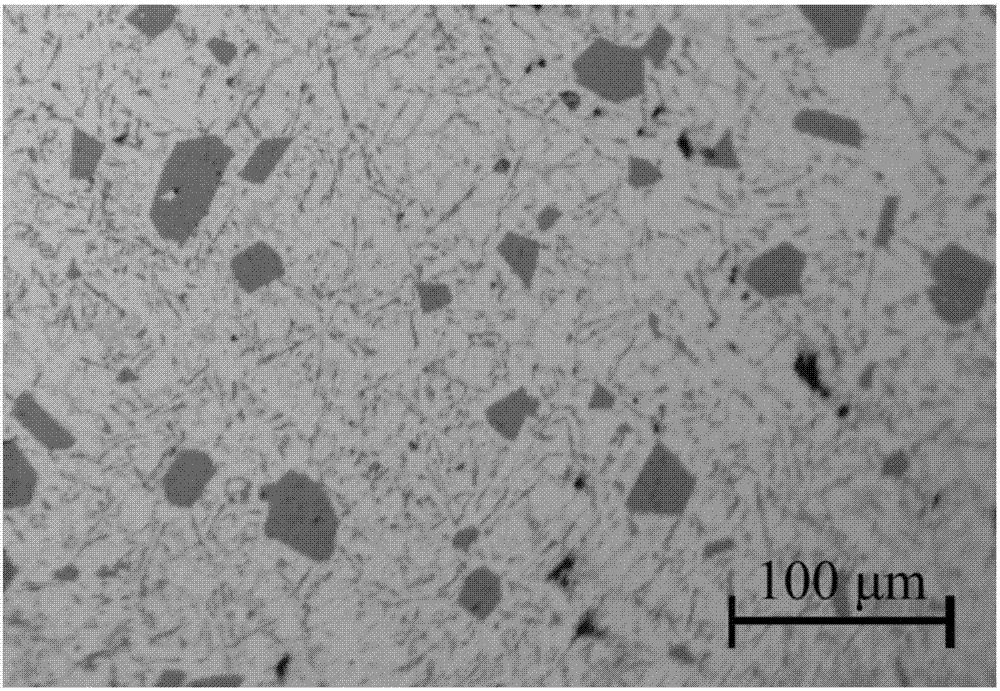

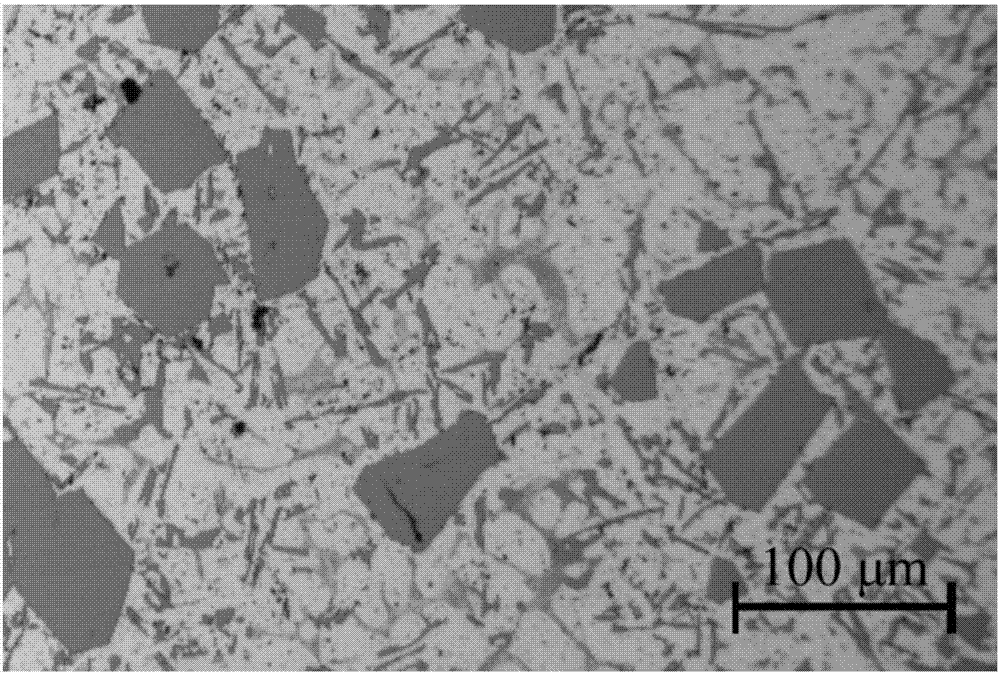

A technology of aluminum-silicon alloy and modification agent, which is applied in the field of hypereutectic aluminum-silicon alloy modification agent, which can solve the problems of coarse primary silicon and achieve the effect of dense structure, uniform distribution and simple modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention are further specifically described below through examples. It should be noted that the following examples and comparative examples are only used to explain the present invention, and should not be regarded as limiting the scope of the claims of the present invention.

[0035] Examples and comparative examples

[0036] In the present invention, the prepared hypereutectic aluminum-silicon alloy raw materials are sequentially melted in a resistance furnace, then the melt is overheated to 750-850° C., and then the Cu-2Be master alloy modifier (containing 2wt% of Be) is pressed Put it into the overheated hypereutectic aluminum-silicon alloy melt, stir it well, and keep it warm for 30-60 minutes; then add conventional refining agents for degassing and refining, and keep it warm for 10-15 minutes; finally, pour the hypereutectic aluminum-silicon alloy melt into castings or For ingot casting, the pouring temperature is 740-800°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com