Dumper hydraulic system

A technology of hydraulic system and dumper, which is applied in the field of dumper, can solve the problems of unpredictability of whether the press cylinder is relieved, complex and scattered management of hydraulic system valve parts, inconvenient fault analysis and troubleshooting, etc., to save opening time, compact structure, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

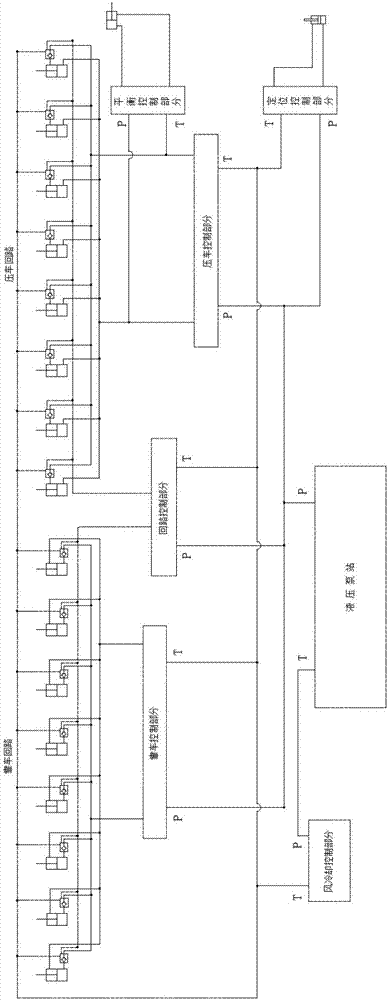

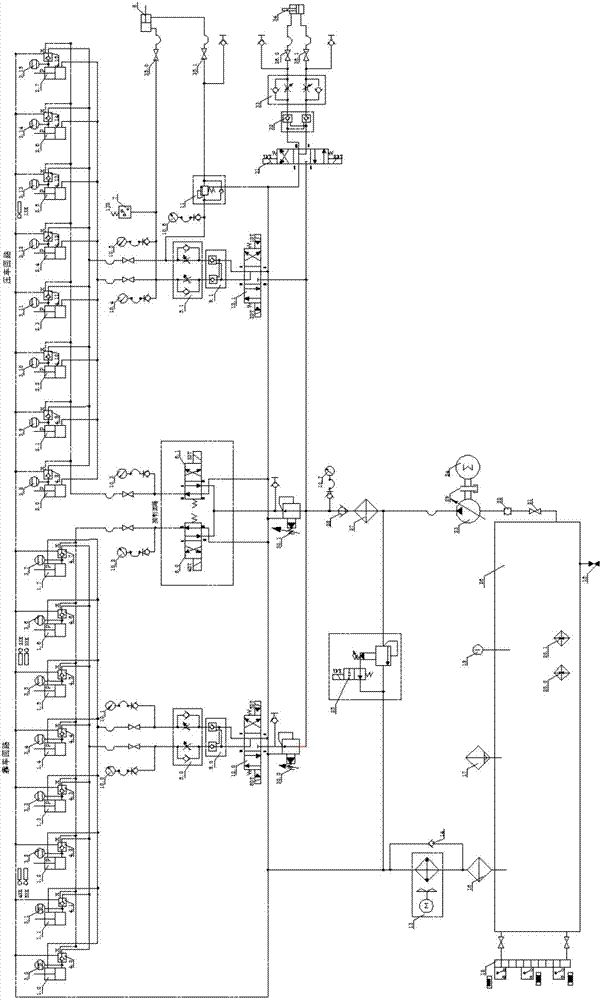

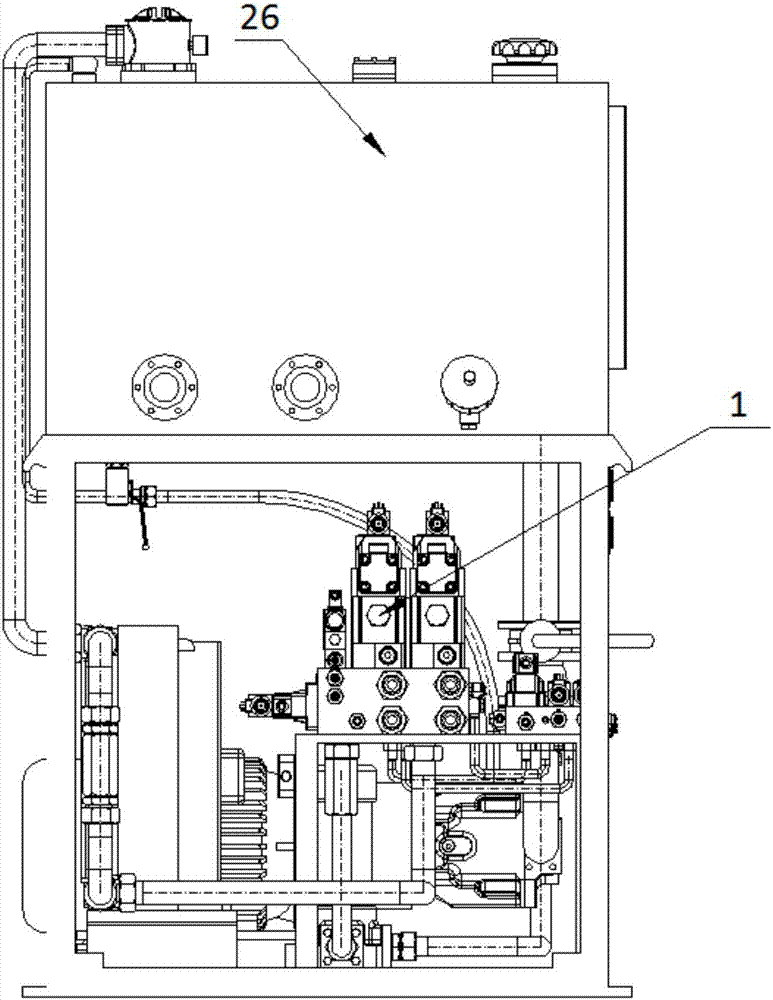

[0023] The dumper hydraulic system shown in the figure also includes a control circuit and a positioning circuit controlled by a hydraulic pump station, wherein the hydraulic pump station uses a single oil pump to supply oil to the main oil circuit, and the main oil circuit is connected to the solenoid valve overflow valve Oil return, the main oil circuit supplies oil to the vehicle circuit oil cylinder group through the pilot pressure reducing valve, electro-hydraulic reversing valve, double hydraulic control check valve, one-way throttle valve and hydraulic control check valve group; The main oil circuit supplies oil to the oil cylinder group of the press circuit through the electro-hydraulic reversing valve, double hydraulic control check valve, one-way throttle valve and hydraulic control check valve group, and the main oil circuit passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com